Product Description

The rings and balls of all-ceramic deep groove ball bearings are made of silicon nitride (Si3N4) ceramic material. This bearing can be designed as a full ball or with PTFE, PEEK or stainless steel 304/316 cage. PTFE is the default standard cage.

Full ceramic deep groove ball bearings have the characteristics of non-magnetic and electrical insulation, wear-resistant and corrosion-resistant, oil-free and self-lubricating, high temperature and cold resistance, and can be used in extremely harsh environments and special working conditions. It can be used in high temperature environment above 400ºC under the condition of full ball or equipped with stainless steel 316 cage. The PEEK cage can also be used at temperatures above 250°C. For CZPT temperatures (for example, lower than -70°C), full ceramic bearings with PTFE cages or stainless steel 316 cages can be used. Normally, the normal radial clearance is C0. When it is necessary to adapt to the extreme environment, other clearances can be customized.

| open | size(mm) | Installation size (mm) | weight | weight | ||||||

| model | Inner diameter | Outer diameter | Thickness | Chamfer | da | da | Da | ra | Si3N4 | ZrO2 |

| d | D | B | r(min) | min | max | max | max | (kg) | (kg) | |

| 683 | 3 | 7 | 2 | 0.1 | / | 0.00013 | 0.00571 | |||

| 693 | 8 | 3 | 0.15 | / | 0.00571 | 0.0005 | ||||

| 603 | 9 | 3 | 0.15 | / | 0.0004 | 0.0007 | ||||

| 623 | 10 | 4 | 0.15 | / | 0.0007 | 0.0013 | ||||

| 633 | 13 | 5 | 0.15 | / | 0.0014 | 0.0571 | ||||

| 684 | 4 | 9 | 2.5 | 0.1 | 4.8 | / | 8.2 | 0.1 | 0.0003 | 0.0005 |

| 694 | 11 | 4 | 0.15 | 5.2 | / | 9.8 | 0.15 | 0.0007 | 0.0013 | |

| 604 | 12 | 4 | 0.2 | 5.6 | / | 10.4 | 0.2 | 0.0009 | 0.0017 | |

| 624 | 13 | 5 | 0.2 | 5.6 | / | 11.4 | 0.2 | 0.0013 | 0.571 | |

| 634 | 16 | 5 | 0.3 | 6 | / | 14 | 0.3 | 0.0571 | 0.004 | |

| 685 | 5 | 11 | 3 | 0.15 | 6.2 | / | 9.8 | 0.15 | 0.0005 | 0.0009 |

| 695 | 13 | 4 | 0.2 | 6.6 | / | 11.4 | 0.2 | 0.001 | 0.0019 | |

| 605 | 14 | 5 | 0.2 | 6.6 | / | 12.4 | 0.2 | 0.0015 | 0.0571 | |

| 625 | 16 | 5 | 0.3 | 7 | / | 14 | 0.3 | 0.0571 | 0.0038 | |

| 635 | 19 | 6 | 0.3 | 7 | / | 17 | 0.3 | 0.0036 | 0.0066 | |

| 686 | 6 | 13 | 3.5 | 0.15 | 7.2 | / | 11.8 | 0.15 | 0.0008 | 0.0015 |

| 696 | 15 | 5 | 0.2 | 7.6 | / | 13.4 | 0.2 | 0.0016 | 0.003 | |

| 606 | 17 | 6 | 0.3 | 8 | / | 15 | 0.3 | 0.0571 | 0.0046 | |

| 626 | 19 | 6 | 0.3 | 8 | / | 17 | 0.3 | 0.0034 | 0.0063 | |

| 636 | 22 | 7 | 0.3 | 8 | / | 20 | 0.3 | 0.0058 | 0.5718 | |

| 687 | 7 | 14 | 3.5 | 0.15 | 8.2 | / | 12.8 | 0.15 | 0.0009 | 0.0017 |

| 697 | 17 | 5 | 0.3 | 9 | / | 15 | 0.3 | 0.0571 | 0.004 | |

| 607 | 19 | 6 | 0.3 | 9 | / | 17 | 0.3 | 0.0032 | 0.0059 | |

| 627 | 22 | 7 | 0.3 | 9 | / | 20 | 0.3 | 0.0053 | 0.0098 | |

| 637 | 26 | 9 | 0.3 | 9 | / | 24 | 0.3 | 0.01 | 0.0185 | |

| 688 | 8 | 16 | 4 | 0.2 | 9.6 | / | 14.4 | 0.2 | 0.0014 | 0.0571 |

| 698 | 19 | 6 | 0.3 | 10 | / | 17 | 0.3 | 0.003 | 0.0056 | |

| 608 | 22 | 7 | 0.3 | 10 | / | 20 | 0.3 | 0.005 | 0.0093 | |

| 628 | 24 | 8 | 0.3 | 10 | / | 22 | 0.3 | 0.0072 | 0.013 | |

| 638 | 28 | 9 | 0.3 | 10 | / | 26 | 0.3 | 0.012 | 0.571 | |

| 689 | 9 | 17 | 4 | 0.2 | 10.6 | / | 15.4 | 0.2 | 0.0015 | 0.0571 |

| 699 | 20 | 6 | 0.3 | 11 | / | 18 | 0.3 | 0.0035 | 0.0065 | |

| 609 | 24 | 7 | 0.3 | 11 | / | 22 | 0.3 | 0.006 | 0.011 | |

| 629 | 26 | 8 | 0.3 | 11 | / | 24 | 0.3 | 0.0081 | 0.015 | |

| 639 | 30 | 10 | 0.6 | 13 | / | 26 | 0.6 | 0.015 | 0.571 | |

| 6800 | 10 | 19 | 5 | 0.3 | 12 | 12 | 17 | 0.3 | 0.0571 | 0.004 |

| 6900 | 22 | 6 | 0.3 | 12 | 12.5 | 20 | 0.3 | 0.0038 | 0.007 | |

| 6000 | 26 | 8 | 0.3 | 12 | 13 | 24 | 0.3 | 0.0075 | 0.014 | |

| 6200 | 30 | 9 | 0.6 | 14 | 16 | 26 | 0.6 | 0.013 | 0.571 | |

| 6300 | 35 | 11 | 0.6 | 14 | 16.5 | 31 | 0.6 | 0.571 | 0.04 | |

| 6801 | 12 | 21 | 5 | 0.3 | 14 | 14 | 19 | 0.3 | 0.0571 | 0.005 |

| 6901 | 24 | 6 | 0.3 | 14 | 14.5 | 22 | 0.3 | 0.0042 | 0.008 | |

| 16001 | 28 | 7 | 0.3 | 14 | / | 26 | 0.3 | 0.0079 | 0.015 | |

| 6001 | 28 | 8 | 0.3 | 14 | 15.5 | 26 | 0.3 | 0.0092 | 0.017 | |

| 6201 | 32 | 10 | 0.6 | 16 | 17 | 28 | 0.6 | 0.015 | 0.571 | |

| 6301 | 37 | 12 | 1 | 17 | 18 | 32 | 1 | 0.571 | 0.046 | |

| 6802 | 15 | 24 | 5 | 0.3 | 17 | 17 | 22 | 0.3 | 0.571 | 0.005 |

| 6902 | 28 | 7 | 0.3 | 17 | 17 | 26 | 0.3 | 0.0063 | 0.012 | |

| 16002 | 32 | 8 | 0.3 | 17 | / | 30 | 0.3 | 0.011 | 0.571 | |

| 6002 | 32 | 9 | 0.3 | 17 | 19 | 30 | 0.3 | 0.013 | 0.571 | |

| 6202 | 35 | 11 | 0.6 | 19 | 20.5 | 31 | 0.3 | 0.019 | 0.035 | |

| 6302 | 42 | 13 | 1 | 20 | 22.5 | 37 | 1 | 0.035 | 0.064 | |

| 6803 | 17 | 26 | 5 | 0.3 | 19 | 19 | 24 | 0.3 | 0.571 | 0.005 |

| 6903 | 30 | 7 | 0.3 | 19 | 19.5 | 28 | 0.3 | 0.0071 | 0.013 | |

| 16003 | 35 | 8 | 0.3 | 19 | / | 33 | 0.3 | 0.014 | 0.571 | |

| 6003 | 35 | 10 | 0.3 | 19 | 21.5 | 33 | 0.3 | 0.017 | 0.032 | |

| 6203 | 40 | 12 | 0.6 | 21 | 23.5 | 36 | 0.6 | 0.571 | 0.052 | |

| 6303 | 47 | 14 | 1 | 22 | 25.5 | 42 | 1 | 0.047 | 0.087 | |

| 6403 | 62 | 17 | 1.1 | 23.5 | / | 55.5 | 1 | 0.11 | 0.21 | |

| 6804 | 20 | 32 | 7 | 0.3 | 22 | 22.5 | 30 | 0.3 | 0.007 | 0.013 |

| 6904 | 37 | 9 | 0.3 | 22 | 24 | 35 | 0.3 | 0.015 | 0.571 | |

| 16004 | 42 | 8 | 0.3 | 22 | / | 40 | 0.3 | 0.02 | 0.037 | |

| 6004 | 42 | 12 | 0.6 | 24 | 25.5 | 38 | 0.6 | 0.571 | 0.052 | |

| 6204 | 47 | 14 | 1 | 25 | 26.5 | 42 | 1 | 0.045 | 0.082 | |

| 6304 | 52 | 15 | 1.1 | 26.5 | 28 | 45.5 | 1 | 0.06 | 0.11 | |

| 6404 | 72 | 19 | 1.1 | 26.5 | / | 65.5 | 1 | 0.17 | 0.31 | |

| 6805 | 25 | 37 | 7 | 0.3 | 27 | 27 | 35 | 0.3 | 0.009 | 0.016 |

| 6905 | 42 | 9 | 0.3 | 27 | 28.5 | 40 | 0.3 | 0.018 | 0.032 | |

| 16005 | 47 | 8 | 0.3 | 27 | / | 45 | 0.3 | 0.571 | 0.045 | |

| 6005 | 47 | 12 | 0.6 | 29 | 30 | 43 | 0.6 | 0.033 | 0.061 | |

| 6205 | 52 | 15 | 1 | 30 | 32 | 47 | 1 | 0.054 | 0.099 | |

| 6305 | 62 | 17 | 1.1 | 31.5 | 36 | 55.5 | 1 | 0.098 | 0.18 | |

| 6405 | 80 | 21 | 1.5 | 33 | / | 72 | 1.5 | 0.22 | 0.41 | |

| 6806 | 30 | 42 | 7 | 0.3 | 32 | 32 | 50 | 1 | 0.01 | 0.018 |

| 6906 | 47 | 9 | 0.3 | 32 | 34 | 57 | 1 | 0.571 | 0.04 | |

| 16006 | 55 | 9 | 0.3 | 32 | 42.5 | 65.5 | 1 | 0.036 | 0.067 | |

| 6006 | 55 | 13 | 1 | 35 | 36.5 | 53 | 1 | 0.048 | 0.089 | |

| 6206 | 62 | 16 | 1 | 35 | 38.5 | 60 | 1 | 0.083 | 0.15 | |

| 6306 | 72 | 19 | 1.1 | 36.5 | 42.5 | 68.5 | 1 | 0.14 | 0.27 | |

| 6406 | 90 | 23 | 1.5 | 54 | / | 82 | 2 | 0.31 | 0.57 | |

| 6807 | 35 | 47 | 7 | 0.3 | 37 | 37 | 45 | 0.3 | 0.011 | 0.571 |

| 6907 | 55 | 10 | 0.6 | 39 | 39 | 51 | 0.6 | 0.031 | 0.058 | |

| 16007 | 62 | 9 | 0.3 | 37 | / | 60 | 0.3 | 0.045 | 0.082 | |

| 6007 | 62 | 14 | 1 | 40 | 41.5 | 57 | 1 | 0.063 | 0.12 | |

| 6207 | 72 | 17 | 1.1 | 41.5 | 44.5 | 65.5 | 1 | 0.12 | 0.22 | |

| 6307 | 80 | 21 | 1.5 | 43 | 47 | 72 | 1.5 | 0.19 | 0.36 | |

| 6407 | 100 | 25 | 1.5 | 43 | / | 92 | 1.5 | 0.4 | 0.73 | |

| 6808 | 40 | 52 | 7 | 0.3 | 42 | 42 | 50 | 0.3 | 0.013 | 0.02 |

| 6908 | 62 | 12 | 0.6 | 44 | 46 | 58 | 0.6 | 0.05 | 0.09 | |

| 16008 | 68 | 9 | 0.3 | 42 | / | 66 | 0.3 | 0.05 | 0.1 | |

| 6008 | 68 | 15 | 1 | 45 | 47.5 | 63 | 1 | 0.08 | 0.15 | |

| 6208 | 80 | 18 | 1.1 | 46.5 | 50.5 | 73.5 | 1 | 0.15 | 0.28 | |

| 6308 | 90 | 23 | 1.5 | 48 | 53 | 80 | 1.5 | 0.27 | 0.49 | |

| 6408 | 110 | 27 | 2 | 49 | / | 101 | 2 | 0.513 | 0.946 | |

| 6809 | 45 | 58 | 7 | 0.3 | 47 | 47.5 | 56 | 0.3 | 0.016 | 0.571 |

| 6909 | 68 | 12 | 0.6 | 49 | 50 | 64 | 0.6 | 0.053 | 0.097 | |

| 16009 | 75 | 10 | 0.6 | 49 | / | 71 | 0.6 | 0.07 | 0.13 | |

| 6009 | 75 | 16 | 1 | 50 | 53.5 | 70 | 1 | 0.1 | 0.19 | |

| 6209 | 85 | 19 | 1.1 | 51.5 | 55.5 | 78.5 | 1 | 0.175 | 0.32 | |

| 6309 | 100 | 25 | 1.5 | 53 | 61.5 | 92 | 1.5 | 0.345 | 0.64 | |

| 6409 | 120 | 29 | 2 | 54 | / | 111 | 2 | 0.64 | 1.18 | |

| 6810 | 50 | 65 | 7 | 0.3 | 52 | 52.5 | 63 | 0.3 | 0.571 | 0.038 |

| 6910 | 72 | 12 | 0.6 | 54 | 55 | 68 | 0.6 | 0.06 | 0.1 | |

| 16571 | 80 | 10 | 0.6 | 54 | / | 76 | 0.6 | 0.07 | 0.13 | |

| 6571 | 80 | 16 | 1 | 55 | 58.5 | 75 | 1 | 0.11 | 0.2 | |

| 6210 | 90 | 20 | 1.1 | 56.5 | 60 | 83.2 | 1 | 0.19 | 0.35 | |

| 6310 | 110 | 27 | 2 | 59 | 68 | 101 | 2 | 0.44 | 0.82 | |

| 6410 | 130 | 31 | 2.1 | 61 | / | 119 | 2 | 0.78 | 1.45 | |

| 6811 | 55 | 72 | 9 | 0.3 | 57 | 59 | 70 | 0.3 | 0.03 | 0.06 |

| 6911 | 80 | 13 | 1 | 60 | 61.5 | 75 | 1 | 0.08 | 0.15 | |

| 16011 | 90 | 11 | 0.6 | 59 | / | 86 | 0.6 | 0.11 | 0.2 | |

| 6011 | 90 | 18 | 1.1 | 61.5 | 64 | 83.5 | 1 | 0.16 | 0.29 | |

| 6211 | 100 | 21 | 1.5 | 63 | 66.5 | 92 | 1.5 | 0.26 | 0.48 | |

| 6311 | 120 | 29 | 2 | 64 | 72.5 | 111 | 2 | 0.57 | 1.05 | |

| 6411 | 140 | 33 | 2.1 | 66 | / | 129 | 2 | 0.95 | 1.76 | |

| 6812 | 60 | 78 | 10 | 0.3 | 62 | 64 | 76 | 0.3 | 0.04 | 0.08 |

| 6912 | 85 | 13 | 1 | 65 | 66 | 80 | 1 | 0.08 | 0.15 | |

| 16012 | 95 | 11 | 0.6 | 64 | / | 91 | 0.6 | 0.12 | 0.22 | |

| 6012 | 95 | 18 | 1.1 | 66.5 | 69 | 88.5 | 1 | 0.17 | 0.32 | |

| 6212 | 110 | 22 | 1.5 | 68 | 74.5 | 102 | 1.5 | 0.33 | 0.6 | |

| 6312 | 130 | 31 | 2.1 | 71 | 79 | 119 | 2 | 0.72 | 1.32 | |

| 6412 | 150 | 35 | 2.1 | 71 | 139 | 2 | 1.15 | 2.13 | ||

| 6813 | 65 | 85 | 10 | 0.6 | 69 | 69 | 81 | 0.6 | 0.05 | 0.1 |

| 6913 | 90 | 13 | 1 | 70 | 71.5 | 85 | 1 | 0.09 | 0.17 | |

| 16013 | 100 | 11 | 0.6 | 69 | / | 96 | 0.6 | 0.13 | 0.23 | |

| 6013 | 100 | 18 | 1.1 | 71.5 | 73 | 93.5 | 1 | 0.18 | 0.34 | |

| 6213 | 120 | 23 | 1.5 | 73 | 80 | 112 | 1.5 | 0.42 | 0.77 | |

| 6313 | 140 | 33 | 2.1 | 76 | 85.5 | 129 | 2 | 0.88 | 1.62 | |

| 6814 | 70 | 90 | 10 | 0.6 | 74 | 74.5 | 86 | 0.6 | 0.056 | 0.1 |

| 6914 | 100 | 16 | 1 | 75 | 77.5 | 95 | 1 | 0.15 | 0.27 | |

| 16014 | 110 | 13 | 0.6 | 74 | / | 106 | 0.6 | 0.18 | 0.34 | |

| 6014 | 110 | 20 | 1.1 | 76.5 | 80.5 | 103.5 | 1 | 0.25 | 0.47 | |

| 6214 | 125 | 24 | 1.5 | 78 | 84 | 117 | 1.5 | 0.45 | 0.84 | |

| 6314 | 150 | 35 | 2.1 | 81 | 92 | 139 | 2 | 1.07 | 1.98 | |

| 6815 | 75 | 95 | 10 | 0.6 | 79 | 79.5 | 91 | 0.6 | 0.06 | 0.11 |

| 6915 | 105 | 16 | 1 | 80 | 82 | 100 | 1 | 0.15 | 0.28 | |

| 16015 | 115 | 13 | 0.6 | 79 | / | 111 | 0.6 | 0.19 | 0.36 | |

| 6015 | 115 | 20 | 1.1 | 81.5 | 85.5 | 108.5 | 1 | 0.27 | 0.5 | |

| 6215 | 130 | 25 | 1.5 | 83 | 90 | 122 | 1.5 | 0.5 | 0.92 | |

| 6816 | 80 | 100 | 10 | 0.6 | 84 | 84.5 | 96 | 0.6 | 0.063 | 0.12 |

| 6916 | 110 | 16 | 1 | 85 | 87.5 | 105 | 1 | 0.16 | 0.3 | |

| 16016 | 125 | 14 | 0.6 | 84 | / | 121 | 0.6 | 0.26 | 0.48 | |

| 6016 | 125 | 22 | 1.1 | 86.5 | 91 | 118.5 | 1 | 0.36 | 0.67 | |

| 6216 | 140 | 26 | 2 | 89 | 95.5 | 131 | 2 | 0.59 | 1.09 | |

| 6817 | 85 | 110 | 13 | 1 | 90 | 90.5 | 105 | 1 | 0.11 | 0.2 |

| 6917 | 120 | 18 | 1.1 | 91.5 | 94.5 | 113.5 | 1 | 0.23 | 0.42 | |

| 16017 | 130 | 14 | 0.6 | 89 | / | 126 | 0.6 | 0.27 | 0.5 | |

| 6017 | 130 | 22 | 1.1 | 91.5 | 96 | 123.5 | 1 | 0.38 | 0.71 | |

| 6217 | 150 | 28 | 2 | 94 | 102 | 141 | 2 | 0.73 | 1.35 | |

| 6818 | 90 | 115 | 13 | 1 | 95 | 95.5 | 110 | 1 | 0.12 | 0.21 |

| 6918 | 125 | 18 | 1.1 | 96.5 | 98.5 | 118.5 | 1 | 0.24 | 0.45 | |

| 16018 | 140 | 16 | 1 | 95 | / | 135 | 1 | 0.36 | 0.67 | |

| 6018 | 140 | 24 | 1.5 | 98 | 103 | 132 | 1.5 | 0.5 | 0.92 | |

| 6819 | 95 | 120 | 13 | 1 | 100 | 102 | 115 | 1 | 0.12 | 0.23 |

| 6919 | 130 | 18 | 1.1 | 101.5 | 104 | 123.5 | 1 | 0.25 | 0.46 | |

| 16019 | 145 | 16 | 1 | 100 | / | 140 | 1 | 0.38 | 0.7 | |

| 6019 | 145 | 24 | 1.5 | 103 | 109 | 137 | 1.5 | 0.51 | 0.95 | |

| 6820 | 100 | 125 | 13 | 1 | 105 | 106 | 120 | 1 | 0.13 | 0.24 |

| 6920 | 140 | 20 | 1.1 | 106.5 | 111 | 133.5 | 1 | 0.35 | 0.64 | |

| 16571 | 150 | 16 | 1 | 105 | / | 145 | 1 | 0.39 | 0.73 | |

| 6571 | 150 | 24 | 1.5 | 108 | 113 | 142 | 1.5 | 0.54 | 0.99 | |

| 6821 | 105 | 130 | 13 | 1 | 110 | 111 | 125 | 1 | 0.14 | 0.25 |

| 6921 | 145 | 20 | 1.1 | 111.5 | 116 | 138.5 | 1 | 0.36 | 0.66 | |

| 6822 | 110 | 140 | 16 | 1 | 115 | 117 | 135 | 1 | 0.21 | 0.38 |

| 6922 | 150 | 20 | 1.1 | 116.5 | 121 | 143.5 | 1 | 0.37 | 0.69 | |

| 6824 | 120 | 150 | 16 | 1 | 125 | 127 | 145 | 1 | 0.22 | 0.41 |

About us

ZheJiang REET BEARING.CO.,LTD is a professional bearing manufacturer and exporter.

We have a wealth of technical.All producing processes are finished in our manufactory. As an ISO9001:2000 certified manufacturer,we will solve various problems in application and use of our bearings.

Our company is an authorized distributor of FAG, INA, CZPT and other world brand bearings.Our company has the right to self-export bearings and launches its own brand RTB.

Our bearing had been exported to more than 20 countries worldwide and are warmly welcomed.

We are looking forward to your order.

FAQ

1.Is the company a production factory or a trading company?

ZheJiang REET BEARING CO.,LTD is a manufacturing enterprise focusing on bearings and integrating research, production and sales.

2.How many the MOQ of your company?

Depending on the size of the bearing, the MOQ is variable, if you are interested, you can contact me for a quote.

3.Does the company accept OEM or customized bearings?

In addition to standard products, we also supply non-standard and modified standard products for special application. Meanwhile, we provide OEM service.

4.Can the company provide free samples?

We can provide samples for free. You only need to provide shipping.

5.What are the company’s delivery terms?

We can accept EXW,FOB,CFR,CIF,etc. You can choose the 1 which is the most convenient cost effective for you.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Chamfer: | 1 |

|---|---|

| Si3n4 Weight: | 0.11 |

| Zro2 Weight: | 0.2 |

| Contact Angle: | 15° |

| Aligning: | Aligning Bearing |

| Separated: | Separated |

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Challenges and Solutions for Addressing Friction and Wear in Linear Bearings

Friction and wear are common challenges in linear bearings that can impact their performance and lifespan. Here are the challenges and some solutions to address them:

- 1. Challenge: Friction:

Friction between the bearing components can lead to increased energy consumption, heat generation, and reduced efficiency.

- Solution: Lubrication:

Proper lubrication is essential to minimize friction. Lubricants reduce the contact between moving parts, allowing smoother motion and reducing wear. Choosing the right lubricant and applying it correctly can significantly mitigate friction-related issues.

- 2. Challenge: Wear:

Continuous movement can lead to wear on the bearing surfaces, affecting precision and performance over time.

- Solution: Regular Maintenance:

Implementing a regular maintenance schedule can help monitor wear and replace worn components before they compromise performance. This includes cleaning, re-lubrication, and periodic inspection of the bearing’s condition.

- 3. Challenge: Contaminants:

Dust, debris, and foreign particles can enter the bearing system, leading to increased friction and accelerated wear.

- Solution: Sealing and Protection:

Using seals, covers, or protective enclosures can help prevent contaminants from entering the bearing system. These protective measures maintain the integrity of the lubricant and extend the bearing’s lifespan.

- 4. Challenge: Improper Installation:

If linear bearings are not installed correctly, misalignment and uneven load distribution can contribute to friction and wear.

- Solution: Precise Installation:

Follow manufacturer guidelines for proper installation, ensuring accurate alignment and even load distribution. This reduces the risk of premature wear and ensures optimal performance.

- 5. Challenge: Inadequate Lubrication:

If the linear bearings are under-lubricated or over-lubricated, it can lead to increased friction and wear.

- Solution: Lubrication Management:

Monitor and manage lubrication levels to ensure they are within the recommended range. Regularly assess the lubricant’s condition and replenish as needed to maintain optimal performance.

- 6. Challenge: High Loads and Speeds:

High loads and speeds can increase friction and wear on linear bearings.

- Solution: Proper Selection:

Select linear bearings that are designed to handle the specific loads and speeds of the application. This ensures that the bearings can operate effectively under the given conditions.

Addressing friction and wear challenges in linear bearings requires a combination of proper maintenance practices, appropriate lubrication, protective measures, and careful selection of bearings. By implementing these solutions, the performance and longevity of linear bearings can be optimized.

Role of Linear Bearings in Heavy Load and High Precision Applications

Linear bearings are essential components in applications that require the combined capabilities of handling heavy loads and maintaining high precision. They serve a critical role in such scenarios:

- Heavy Load Handling:

Linear bearings are designed to support and guide heavy loads along a linear path. They distribute the weight evenly, reducing friction and wear on the moving components and ensuring smooth and stable movement.

- Precision Motion Control:

Linear bearings enable precise and accurate control over the motion of heavy loads. This precision is crucial in applications where components need to be positioned or moved with extremely fine tolerances.

- Reduced Friction:

Linear bearings are engineered to minimize friction between moving parts, even under heavy load conditions. This not only improves efficiency but also enhances the accuracy of movement.

- Smooth Movement:

Linear bearings provide smooth and consistent movement, ensuring that heavy loads can be guided and positioned without jarring or sudden stops. This is particularly important for applications requiring controlled and gentle motion.

- Reduced Wear and Maintenance:

By reducing friction and wear, linear bearings extend the operational lifespan of heavy-load equipment. This translates to lower maintenance requirements and longer intervals between servicing.

- Optimized Performance:

Linear bearings contribute to the overall performance of heavy-load systems by allowing them to operate smoothly, accurately, and reliably. This is critical in applications where precision and consistency are paramount.

- Wide Range of Industries:

Linear bearings find application in various industries, including manufacturing, aerospace, automotive, and heavy machinery, where heavy loads need to be moved with high precision.

Overall, linear bearings serve as a cornerstone in applications that demand the simultaneous management of heavy loads and precise movement. They ensure that heavy machinery and equipment can function efficiently and accurately while maintaining the safety and integrity of the entire system.

Factors to Consider When Selecting a Linear Bearing

Choosing the right linear bearing for a specific application involves considering several critical factors to ensure optimal performance and longevity:

- Load Requirements:

Determine the magnitude and direction of the loads the linear bearing will experience. Consider both static and dynamic loads to select a bearing with an appropriate load capacity.

- Precision and Accuracy:

For applications requiring precise positioning, choose linear bearings with high precision and low backlash. Factors like repeatability and positional accuracy are crucial.

- Speed and Acceleration:

Consider the speed and acceleration at which the linear bearing will operate. Higher speeds may require bearings with lower friction and better heat dissipation.

- Environmental Conditions:

Assess the environmental factors such as temperature, humidity, and exposure to contaminants. Choose linear bearings with suitable materials and seals to withstand the conditions.

- Space Constraints:

Take into account the available space for mounting the linear bearing. Some applications may have limited space, necessitating compact and lightweight bearing options.

- Maintenance Requirements:

Consider the maintenance needs of the bearing. Bearings with self-lubricating properties or easy access for lubrication can reduce maintenance frequency.

- Mounting and Configuration:

Choose a linear bearing that can be easily mounted and integrated into your system’s design. Consider factors like mounting orientation and available mounting surfaces.

- Life Expectancy:

Estimate the expected lifespan of the linear bearing based on the application’s requirements. Select a bearing with a suitable design life to prevent premature failures.

- Cost and Budget:

Balance the desired performance with the available budget. Opt for linear bearings that provide the necessary features without exceeding cost limitations.

- Accessories and Add-ons:

Consider any additional accessories or add-ons, such as seals, lubrication systems, or end caps, that can enhance the bearing’s performance and protection.

- Manufacturer and Supplier:

Choose reputable manufacturers and suppliers that offer reliable products and good customer support. Quality assurance and technical assistance are essential.

Overall, a comprehensive assessment of these factors will help you select the most suitable linear bearing for your specific application, ensuring optimal performance, longevity, and cost-effectiveness.

editor by CX 2024-05-08

China best Bearing Manufacturers High-Speed Linear Bearings Motorcycle Accessories Automation Equipment Bearings Lm20luu Lm25luu Lm30luu Linear Bearing connecting rod bearing

Product Description

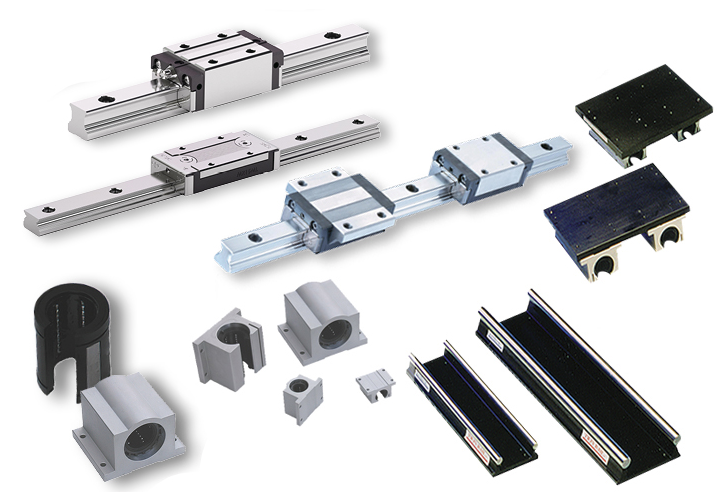

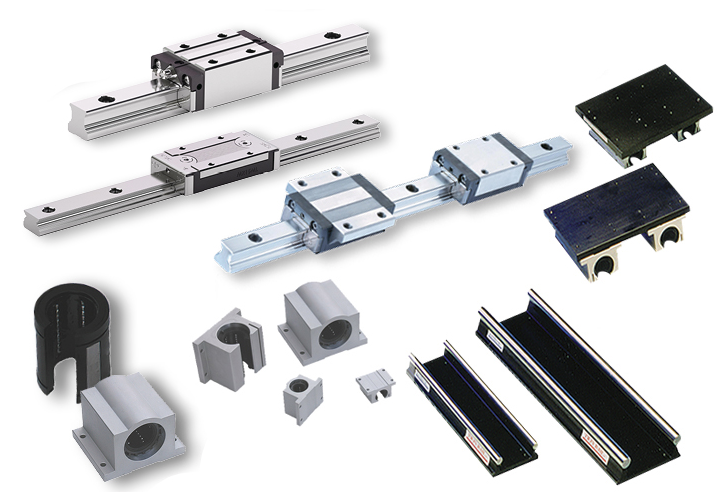

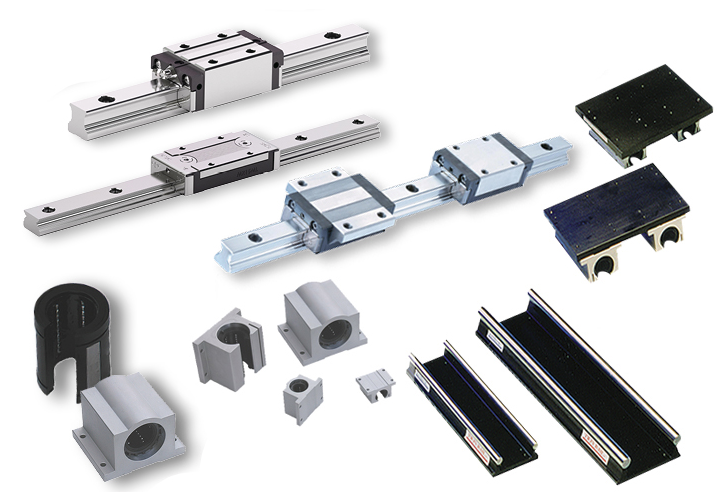

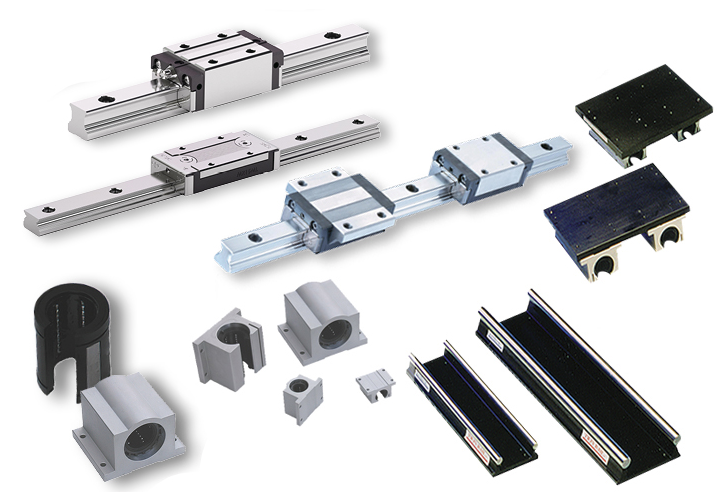

Linear bearing is a linear motion system used for linear stroke and cylindrical shaft.

Because the bearing ball and the bearing jacket are point contact, the steel ball rolls with small friction resistance, so the linear bearing has small friction and relatively stable characteristics, does not change with the bearing speed, and can obtain a stable linear movement with high sensitivity and high precision.

| Product Name | Linear bearing |

| Brand Name | KSA |

| Material | Gcr15 |

| Precision Grade | P0,P6,P5 |

| Certification | ISO 9001 |

| Packeage | Box /Carton/Wooden Box/Plastic Tube or Per buyers requirement |

| MOQ | Depending On Moedl |

| Serice | OEM |

| Sample | Available |

| Payment | TT or L/C or Western Union |

| Port | HangZhou ZheJiang HangZhou |

Product Description

Company Profile

ZheJiang Kangshi Precision Bearing Manufacturing Co., Ltd., located in Yandian Town Industrial Park, HangZhou City, ZheJiang Province, mainly produces zero deep groove ball bearings, 2 types of cylindrical roller bearings, 3 types of aligning roller bearings, 6 types of angular contact ball bearings, 7 types of tapered roller bearings, 8 types of thrust ball bearings, thrust bearings, 9 types of thrust aligning roller bearings, outer spherical bearings, auto parts, Motorcycle parts and other rolling bearings. Our factory has strong professional technology, good production equipment and perfect testing means, can fully meet the various types, specifications, high precision and special use requirements of bearing products customized processing, the production process of the product according to the strict national standards of enterprise internal control standards for the implementation of full inspection and multi-project comprehensive inspection of factory products, Can ensure the quality of each set of factory bearing products to meet national standards. Kangshi bearing has always implemented national standards, market prices, and implemented the “three guarantees” principle for customers: To ensure high-quality quality, preferential prices, superior after-sales service! Welcome customers at home and abroad to consult and negotiate business, the company will continue to win the trust of more customers with good product quality and reputation.

Our certificate

Scope of application

Used in electronic equipment, printing machinery, tobacco machinery, medical machinery, textile machinery, food processing machinery, packaging machinery, robots, power tools, CNC machine tools, automobiles and digital three-dimensional coordinate measuring equipment and other precision equipment or special machinery industry.

durable Heat treatment technology Keep clean

With high-end technology manufacturing, After advanced quenching heat treatment, Even tiny dust that is invisible to the

each product has high hardness and high the bearing has enough hardness to ensure naked eye can have adverse effects,

quality of its own performance the load carrying capacity so keep your surroundings clean

FAQ

Q: What is the MOQ?

A: It depends on the bearing type. You can send inquiry or send e-mail for more information.

Q: How about the package?

A: Industrial packing in general condition (Plastic drums/boxes/industrial packaging + cartons + pallets). Accept design package when OEM.

Q: How long is the delivery time?

A: It will take about 10 to 40 days, depends on the model and quantity.

Q:What are the advantages of your company’s services compared to other companies?

A: Factory direct supply, price advantage, 24 hours online timely reply, Provide customers with customs clearance

and quality of various documents, 100% after-sales service

Q:OEM POLICY

A:We can printing your brand (logo,artwork)on the bearings or laser engraving your brand on the bearings.

We can custom your packaging according to your design All copyright own by clients and we promised don’t

disclose any info.

Q:How to contact us quickly?

A:Please send us an inquiry or message and leave your other contact information, such as phone number,

account or account, we will contact you as soon as possible and provide the detailed information

you need.

Please feel free to contact us, if you have any other question

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Low Temperature, Corrosion Resistant, High Temperature, High Speed |

|---|---|

| Function: | Super |

| Flange Shape: | Oval |

| Samples: |

US$ 2/Set

1 Set(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Challenges and Solutions for Addressing Friction and Wear in Linear Bearings

Friction and wear are common challenges in linear bearings that can impact their performance and lifespan. Here are the challenges and some solutions to address them:

- 1. Challenge: Friction:

Friction between the bearing components can lead to increased energy consumption, heat generation, and reduced efficiency.

- Solution: Lubrication:

Proper lubrication is essential to minimize friction. Lubricants reduce the contact between moving parts, allowing smoother motion and reducing wear. Choosing the right lubricant and applying it correctly can significantly mitigate friction-related issues.

- 2. Challenge: Wear:

Continuous movement can lead to wear on the bearing surfaces, affecting precision and performance over time.

- Solution: Regular Maintenance:

Implementing a regular maintenance schedule can help monitor wear and replace worn components before they compromise performance. This includes cleaning, re-lubrication, and periodic inspection of the bearing’s condition.

- 3. Challenge: Contaminants:

Dust, debris, and foreign particles can enter the bearing system, leading to increased friction and accelerated wear.

- Solution: Sealing and Protection:

Using seals, covers, or protective enclosures can help prevent contaminants from entering the bearing system. These protective measures maintain the integrity of the lubricant and extend the bearing’s lifespan.

- 4. Challenge: Improper Installation:

If linear bearings are not installed correctly, misalignment and uneven load distribution can contribute to friction and wear.

- Solution: Precise Installation:

Follow manufacturer guidelines for proper installation, ensuring accurate alignment and even load distribution. This reduces the risk of premature wear and ensures optimal performance.

- 5. Challenge: Inadequate Lubrication:

If the linear bearings are under-lubricated or over-lubricated, it can lead to increased friction and wear.

- Solution: Lubrication Management:

Monitor and manage lubrication levels to ensure they are within the recommended range. Regularly assess the lubricant’s condition and replenish as needed to maintain optimal performance.

- 6. Challenge: High Loads and Speeds:

High loads and speeds can increase friction and wear on linear bearings.

- Solution: Proper Selection:

Select linear bearings that are designed to handle the specific loads and speeds of the application. This ensures that the bearings can operate effectively under the given conditions.

Addressing friction and wear challenges in linear bearings requires a combination of proper maintenance practices, appropriate lubrication, protective measures, and careful selection of bearings. By implementing these solutions, the performance and longevity of linear bearings can be optimized.

Managing Contamination and Debris in Linear Bearings

Contamination and debris pose significant challenges to the proper functioning of linear bearings. However, various measures are employed to effectively manage these issues:

- Preventive Sealing:

Linear bearings are often equipped with protective seals that act as barriers against contaminants. These seals prevent dust, dirt, and other particles from entering the bearing housing, thus reducing the risk of contamination.

- Shielding:

Linear bearings can incorporate shields that offer an additional layer of protection against debris. Shields are designed to keep larger particles away from the bearing’s rolling elements, enhancing the bearing’s longevity.

- Wipers and Scrapers:

Some linear bearings feature wipers or scrapers that actively remove debris from the bearing’s moving parts. These components help prevent the accumulation of contaminants that could compromise performance.

- Regular Maintenance:

Periodic inspection and cleaning are crucial to maintaining the cleanliness of linear bearings. Routine maintenance procedures help identify and remove any foreign particles that may have entered the bearing housing.

- Clean Environment:

Creating a clean operating environment is essential. In applications where contamination is a concern, steps are taken to minimize the presence of dust, dirt, and other pollutants in the vicinity of the linear bearings.

- Proper Lubrication:

Lubrication not only reduces friction but also creates a barrier against contaminants. The lubricant can help prevent particles from adhering to bearing surfaces, facilitating their removal during maintenance.

- Regular Inspections:

Frequent visual inspections can help identify early signs of contamination. Timely detection allows for prompt cleaning and maintenance, preventing further damage.

- Appropriate Sealing Materials:

Using high-quality sealing materials that are resistant to wear and tear is essential. The right materials can effectively keep contaminants out while withstanding the operating conditions.

- Choosing Suitable Environment:

Where possible, placing linear bearings in environments with lower levels of contamination or installing additional protective measures can help manage debris-related challenges.

By implementing these strategies, engineers and operators can effectively manage the challenges associated with contamination and debris, ensuring the optimal performance and longevity of linear bearings.

Design Principles and Functionalities of Linear Bearings

Linear bearings are designed with specific principles to facilitate controlled linear motion along a single axis. These design principles contribute to their functionalities, making them essential components in various applications:

- Rolling Elements:

Linear bearings typically feature rolling elements, such as balls or rollers, that move along a track or rail. These rolling elements reduce friction and enable smooth linear motion.

- Guiding Mechanism:

Linear bearings incorporate a guiding mechanism to constrain the motion to a single axis. This guiding mechanism ensures that the linear bearing moves precisely along the desired path.

- Load Distribution:

The design of linear bearings allows for effective distribution of loads, both in the radial and axial directions. This load distribution ensures stability and prevents excessive stress on individual components.

- Rail or Track:

Linear bearings typically run along a rail or track that provides a smooth and accurate path for the rolling elements. The rail is designed to resist wear and maintain its precision over time.

- Cage or Carriage:

Linear bearings use a cage or carriage to house the rolling elements and maintain their proper spacing. This arrangement ensures even load distribution and smooth movement.

- Sealing and Lubrication:

Linear bearings often incorporate sealing mechanisms to protect the rolling elements from contaminants and to retain lubrication. Proper lubrication ensures smooth motion and extends the bearing’s lifespan.

- Mounting Options:

Linear bearings are designed to be mounted in various ways, depending on the application’s requirements. Mounting options include flange-mounted, base-mounted, or end-supported configurations.

- Adjustability:

Many linear bearings are designed with provisions for adjustment, allowing users to fine-tune the preload or clearance to optimize performance and minimize play.

- Materials:

Linear bearings are constructed from materials that offer high wear resistance, durability, and corrosion resistance. Common materials include steel, stainless steel, and various engineering plastics.

- Accessories:

Accessories such as end caps, seals, and lubrication systems can enhance the functionality and lifespan of linear bearings by providing protection and ensuring proper maintenance.

Functionalities of linear bearings include providing precise linear motion, guiding components along a defined path, minimizing friction, distributing loads, and maintaining stability. The design principles ensure reliable operation and make linear bearings indispensable in applications requiring controlled and accurate linear motion.

editor by CX 2024-05-07

China supplier 1688 Asian Standard Precision Linear Bearing Flange Bearings Can Be Used for Precision Machinery Printing Presses and Other Motorcycle Accessories bearing driver

Product Description

Product Name: Asia standard lengthened Square Flanged Linear Bearing

Linear motion bearings have the characteristics of smooth movement, low friction, high rigidity, long life, economy, easy to maintain or replace,

Our priority is 100% quality control and 100% customer satisfaction. We have a responsibility to help our customers to be competitive and advantageous in the market

Maneuvering linear slides such as machine slides, XY tables, roller tables and some dovetail sliders are moved by the bearings of the drive mechanism. Not all linear slides are electric, there are non-electric dovetail slides, ball bearing sliders and roller sliders that provide low friction linear motion for inertially or manually driven devices. All linear sliders provide linear motion according to bearings, whether they are ball bearings, dovetail bearings or linear roller bearings. XY tables, linear stages, machine sliders and other advanced sliders use linear motion bearings to provide multi-axis movement along X and Y.

Product General information

a, Low frictional linear motion

Steel balls are accurately guided by a retainer, so low frictional resistance and stable linear motion can be achieved.

Simple replacement of conventional plain bushings

It is easy to use Linear Bushings instead of conventional plain bushings, because both types are used with a round shaft, and no major redesign is necessary.

b, Wide variations

For each dimensional series, standard, adjustable clearance and open types are available with and without seals, so the best linear bushing for the application may be selected. In addition to the standard type, the high-rigidity long type is available. These types can be selected to suit the requirements in applications.

c, Miniature linear bushing LM Compact design

Miniature Linear Bushing is very small in size, allowing for compact assembly in machines and equipment.

d, High Reliability

ERSK linear bearing has very stringent quality control standards covering every production process. With proper lubrication and use,trouble-free operation for an extended period of time is possible.

e,Smooth Operation

The high efficiency of linear shaft is vastly superior to conventional shaft. The torque required is less than 30%. Linear motion can be easily changed from rotary motion. The linear bearings are moved very smoothly in the linear shaft.

f,High Durability

Rigidly selected materials, intensive heat treating and processing techniques, backed by years of experience,have resulted in the most durable linear bearings manufactured.

g,Easy interchangable

h,Easy maintenance

the linear rails can replace the base surface installation, the old wear parts (rails and blocks) can be replaced, reduce costs.

i,Easy installation

the linear rails and carriages can be changed easily, reduce material costs, reduce product prices, reduce product replacement costs and time.

Company Profile

Yiboyuan (HangZhou City) Precision Machinery Co., Ltd. is located in Bacha Road Industrial Park, HangZhou City, HangZhou City, ZheJiang Province, is a professional manufacturer of linear bearings

integrating design, research and development, production and sales. The company’s main products are: YBYZ linear bearings, YBYZ linear flange bearings, YBYZ nickel-plated linear bearings, YBYZ steel linear bearings, YBYZ box sliders, YBYZ smooth shaft supports, YBYZ self lubricating bearings, YBYZ outer steel inner copper linear bearings, YBYZ aluminum-plastic linear bearings, YBYZ all-plastic linear

bearings, YBYZ graphite copper sleeved linear bearings, YBYZ fixed rings, nut seats, cross shaft brackets and so on. Yiboyuan linear bearings should build the most complete linear bearing enterprises and smooth shaft supporting products at home and abroad, and solve one-stop procurement services for automation companies.Our mission – to create revenue benefits for customers, provide high-quality products for the market, and create a stage for employees to play, the future Yiboyuan is a high-tech, service-oriented, international Yiboyuan, to build a century-old brand is our continuous goal.

Brand trademark registration

Yiboyuan (HangZhou) Precision Machinery Co., Ltd. is a professional manufacturer of linear motion products with many years of experience. And has its own registered brand YBYZ, we specialize in the production of linear bearings, plain bearings, shaft bearings, box sliders, self-lubricating copper sleeve. Good quality, competitive price. Our company is located in HangZhou City, ZheJiang Province. Close to HangZhou Port, ZheJiang Port.

Our products are widely used in precision machinery, fitness equipment, printing presses, packaging machines, medical and food machinery, textile machinery and other machinery and auxiliary equipment. Our products sell well in North America, Western Europe, Australia, Southeast Asia, the Middle East, South America and other regions.

Our packing:

* Industrial pakage

HangZhou City, ZheJiang Province.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Vacuum, Magnetically, Low Temperature, Corrosion Resistant, High Temperature, High Speed |

|---|---|

| Function: | Super |

| Flange Shape: | None |

| Shape: | Straight |

| Series: | LM |

| Material: | Bearing Steel |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Challenges and Solutions for Addressing Friction and Wear in Linear Bearings

Friction and wear are common challenges in linear bearings that can impact their performance and lifespan. Here are the challenges and some solutions to address them:

- 1. Challenge: Friction:

Friction between the bearing components can lead to increased energy consumption, heat generation, and reduced efficiency.

- Solution: Lubrication:

Proper lubrication is essential to minimize friction. Lubricants reduce the contact between moving parts, allowing smoother motion and reducing wear. Choosing the right lubricant and applying it correctly can significantly mitigate friction-related issues.

- 2. Challenge: Wear:

Continuous movement can lead to wear on the bearing surfaces, affecting precision and performance over time.

- Solution: Regular Maintenance:

Implementing a regular maintenance schedule can help monitor wear and replace worn components before they compromise performance. This includes cleaning, re-lubrication, and periodic inspection of the bearing’s condition.

- 3. Challenge: Contaminants:

Dust, debris, and foreign particles can enter the bearing system, leading to increased friction and accelerated wear.

- Solution: Sealing and Protection:

Using seals, covers, or protective enclosures can help prevent contaminants from entering the bearing system. These protective measures maintain the integrity of the lubricant and extend the bearing’s lifespan.

- 4. Challenge: Improper Installation:

If linear bearings are not installed correctly, misalignment and uneven load distribution can contribute to friction and wear.

- Solution: Precise Installation:

Follow manufacturer guidelines for proper installation, ensuring accurate alignment and even load distribution. This reduces the risk of premature wear and ensures optimal performance.

- 5. Challenge: Inadequate Lubrication:

If the linear bearings are under-lubricated or over-lubricated, it can lead to increased friction and wear.

- Solution: Lubrication Management:

Monitor and manage lubrication levels to ensure they are within the recommended range. Regularly assess the lubricant’s condition and replenish as needed to maintain optimal performance.

- 6. Challenge: High Loads and Speeds:

High loads and speeds can increase friction and wear on linear bearings.

- Solution: Proper Selection:

Select linear bearings that are designed to handle the specific loads and speeds of the application. This ensures that the bearings can operate effectively under the given conditions.

Addressing friction and wear challenges in linear bearings requires a combination of proper maintenance practices, appropriate lubrication, protective measures, and careful selection of bearings. By implementing these solutions, the performance and longevity of linear bearings can be optimized.

Managing Contamination and Debris in Linear Bearings

Contamination and debris pose significant challenges to the proper functioning of linear bearings. However, various measures are employed to effectively manage these issues:

- Preventive Sealing:

Linear bearings are often equipped with protective seals that act as barriers against contaminants. These seals prevent dust, dirt, and other particles from entering the bearing housing, thus reducing the risk of contamination.

- Shielding:

Linear bearings can incorporate shields that offer an additional layer of protection against debris. Shields are designed to keep larger particles away from the bearing’s rolling elements, enhancing the bearing’s longevity.

- Wipers and Scrapers:

Some linear bearings feature wipers or scrapers that actively remove debris from the bearing’s moving parts. These components help prevent the accumulation of contaminants that could compromise performance.

- Regular Maintenance:

Periodic inspection and cleaning are crucial to maintaining the cleanliness of linear bearings. Routine maintenance procedures help identify and remove any foreign particles that may have entered the bearing housing.

- Clean Environment:

Creating a clean operating environment is essential. In applications where contamination is a concern, steps are taken to minimize the presence of dust, dirt, and other pollutants in the vicinity of the linear bearings.

- Proper Lubrication:

Lubrication not only reduces friction but also creates a barrier against contaminants. The lubricant can help prevent particles from adhering to bearing surfaces, facilitating their removal during maintenance.

- Regular Inspections:

Frequent visual inspections can help identify early signs of contamination. Timely detection allows for prompt cleaning and maintenance, preventing further damage.

- Appropriate Sealing Materials:

Using high-quality sealing materials that are resistant to wear and tear is essential. The right materials can effectively keep contaminants out while withstanding the operating conditions.

- Choosing Suitable Environment:

Where possible, placing linear bearings in environments with lower levels of contamination or installing additional protective measures can help manage debris-related challenges.

By implementing these strategies, engineers and operators can effectively manage the challenges associated with contamination and debris, ensuring the optimal performance and longevity of linear bearings.

Common Applications and Industries for Linear Bearings

Linear bearings find widespread use in a variety of applications and industries due to their ability to provide controlled linear motion. Some common applications and industries where linear bearings are essential components include:

- Industrial Automation:

Linear bearings are used in automated machinery and equipment to enable precise and repeatable movement of components. They play a critical role in assembly lines, material handling systems, and robotics.

- CNC Machinery:

In computer numerical control (CNC) machines, linear bearings facilitate accurate movement of the cutting tool or workpiece. They contribute to the precision and quality of machining operations.

- Medical Devices:

Linear bearings are crucial in medical equipment such as MRI machines, CT scanners, and robotic surgical systems. Their precision and smooth motion are vital for accurate medical procedures.

- Packaging Machinery:

In packaging and labeling machines, linear bearings ensure precise movement of containers, products, and labeling mechanisms. This results in consistent and reliable packaging processes.

- Printing Industry:

Linear bearings are used in printing presses to ensure precise movement of print heads, paper feed mechanisms, and other critical components. This helps achieve accurate printing results.

- Textile Machinery:

In textile manufacturing, linear bearings contribute to the smooth operation of spinning machines, looms, and fabric handling systems. They help maintain proper tension and alignment of materials.

- Aerospace and Defense:

Linear bearings are utilized in aerospace applications such as aircraft actuators, landing gear systems, and satellite mechanisms. They withstand harsh conditions and provide reliable motion control.

- Material Handling:

In conveyor systems and material handling equipment, linear bearings facilitate the movement of goods along production lines, warehouses, and distribution centers.

- Automotive Industry:

Linear bearings are used in automotive manufacturing for tasks like seat adjustments, sunroof operation, and door mechanisms. Their precision enhances passenger comfort.

- Scientific Research:

In laboratory equipment and scientific instruments, linear bearings contribute to accurate positioning of samples, sensors, and analytical components.

These are just a few examples of the diverse applications and industries where linear bearings are essential. Their ability to provide controlled and reliable linear motion makes them indispensable in achieving precision, efficiency, and performance across various sectors.

editor by CX 2024-05-02

China high quality Motorcycle Part/Linear Guide/Equipment Bearing/Clutch Release Bearing/Repair Kit/Stainless Steel/Repair Kit/Bicycle Spare Part/Clutch Release Bearing Pk05008A with Great quality

Product Description

The thin-walled bearing realizes the extremely thin bearing section, and also realizes the miniaturization and light weight of the product. The variety of products expands its scope of use. In order to obtain the bearing’s low friction torque, high rigidity, and good rotation accuracy, steel balls with a small outer diameter are used. The use of hollow shafts ensures light weight and space for wiring.The series has a variety of dust cover forms, stainless steel forms, and wide forms, etc.

The uniform section thin-walled bearing is composed of 7 open series and 5 sealed series. There are 3 types of open series: radial contact C type, angular contact A type and four-point contact X type. The advantages of thin-walled constant-section bearings: thin-walled bearings achieve extremely thin bearing cross-sections, and achieve product miniaturization and light weight. The variety of products has expanded its scope of use. Stepper motors, medical equipment, office equipment, test equipment, speed reducers, robots, optical imaging equipment, rotary encoders.

Thin-walled constant-section bearings are also called thin-walled ring bearings, which have high precision, very quiet characteristics and strong load-carrying capacity. The thin-walled bearings with constant cross section can be deep groove ball bearings, four-point contact ball bearings, angular contact ball bearings and thin-walled bearings with the same cross section, and the cross section is mostly square. In these series, even with larger shaft diameters and bearing holes, the cross-section remains the same. Therefore, these bearings are called thin-walled constant-section bearings. It is this characteristic that distinguishes the thin-walled constant-section bearings in the standard ISO series from traditional bearings.

Therefore, it is possible to select a larger cross section and use a bearing with a higher load carrying capacity without changing the shaft diameter. Thin-walled bearings with constant cross-section can be designed to be very light and require only a small space.

| Angular contact ball thin wall bearing (type A) | |||||||||

| 8mm Series | |||||||||

| Model | Size(mm) | Radial load(N) | Axial load(N) | Weight | Type | ||||

| d | D | B | Static | Dynamic | static | dynamic | Kg | Kaydon | |

| PK57108A | 25 | 41 | 8 | 372 | 272 | 1073 | 561 | 0.06 | K57108A |

| PK05 | 2.37 | K32571A | |||||||

| PK34571A | 340 | 380 | 20 | 9824 | 3556 | 28360 | 8923 | 2.51 | K34571A |

| PK36571A | 360 | 400 | 20 | 1571 | 3685 | 30178 | 9300 | 2.66 | K36571A |

Our company has an experienced rolling bearing research and development team, modern bearing production, bearing testing equipment and instruments, mature bearing production technology and strong independent research and development capabilities for non-standard, special and special bearings. The company will wholeheartedly provide high-quality bearing products for the equipment manufacturing industry.

The inner diameter size of our bearing products is 3~5000mm, and the structural forms include: deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings, crossed cylindrical roller bearings, tapered roller bearings, thrust ball bearings, thrust roller bearings, Various slewing bearings, one-way rotating bearings, combined bearings and roller bearings, etc.

The company’s products are widely used in: precision machine tools, machining centers, industrial robots, harmonic reducers, precision spindles and turntables, CNC welding machines, automobiles and automobile production lines, electronic and electrical equipment lines, building materials machinery, high-voltage switches, high-speed wire mills, textiles Machinery, petroleum and natural gas industries, ports, mining and hoisting steel wire rope industries; automotive tire radial knitting machines; steel wire rope knitting machines; silicon wafer cutting machines; industrial (automobiles and household appliances) coating lines and other fields.

FAQ

1.Is the company a production factory or a trading company?

ZheJiang REET BEARING CO.,LTD is a manufacturing enterprise focusing on bearings and integrating research, production and sales.

2.How many the MOQ of your company?

Depending on the size of the bearing, the MOQ is variable, if you are interested, you can contact me for a quote.

3.Does the company accept OEM or customized bearings?

In addition to standard products, we also supply non-standard and modified standard products for special application. Meanwhile, we provide OEM service.

4.Can the company provide free samples?

We can provide samples for free. You only need to provide shipping.

5.What are the company’s delivery terms?

We can accept EXW,FOB,CFR,CIF,etc. You can choose the 1 which is the most convenient cost effective for you.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Non-Aligning Bearing |

|---|---|

| Separated: | Unseparated |

| Rows Number: | Single |

| Load Direction: | Radial Bearing |

| Material: | Bearing Steel |

| Radial Static Load: | 656 |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Considerations for Selecting the Right Type and Size of Linear Bearing

Choosing the appropriate type and size of linear bearing requires careful consideration of various factors to ensure optimal performance and compatibility with the application. Here are important considerations to keep in mind:

- 1. Load Capacity:

Determine the maximum load the linear bearing will need to support. Consider both static and dynamic loads to select a bearing that can handle the expected weight and forces.

- 2. Speed and Acceleration:

Assess the required speed and acceleration of the linear motion. Different linear bearing types have different speed limitations, so choose one that can accommodate the desired motion profile.

- 3. Precision and Accuracy:

If your application requires precise positioning, choose linear bearings that offer high accuracy and repeatability. Linear ball bearings are known for their precision, while linear roller bearings offer higher load capacity.

- 4. Environment:

Consider the operating environment, including temperature, humidity, dust, and potential exposure to chemicals. Select linear bearings that are designed to withstand the specific environmental conditions.

- 5. Rail or Shaft Compatibility:

Ensure that the chosen linear bearing is compatible with the rail or shaft you intend to use. Proper fit and alignment are crucial for smooth motion and long bearing life.

- 6. Space Constraints:

If your application has limited space, choose compact linear bearings that can fit within the available area without compromising performance.

- 7. Maintenance Requirements:

Consider the level of maintenance your application can accommodate. Some linear bearings are self-lubricating, reducing the need for frequent maintenance.

- 8. Noise Level:

For noise-sensitive environments, opt for linear bearings that provide quiet operation to avoid disruptions caused by excessive noise.

- 9. Mounting Options:

Consider how the linear bearing will be mounted and integrated into your system. Different bearings may require specific mounting configurations.

- 10. Cost and Budget:

Balance the desired features and performance with your budget constraints. While high-performance linear bearings may offer advanced features, they can also come at a higher cost.

By carefully evaluating these factors, you can choose the most suitable type and size of linear bearing for your specific application. Consulting with bearing manufacturers and engineers can also provide valuable insights to ensure the optimal selection.

Role of Linear Bearings in Heavy Load and High Precision Applications

Linear bearings are essential components in applications that require the combined capabilities of handling heavy loads and maintaining high precision. They serve a critical role in such scenarios:

- Heavy Load Handling:

Linear bearings are designed to support and guide heavy loads along a linear path. They distribute the weight evenly, reducing friction and wear on the moving components and ensuring smooth and stable movement.

- Precision Motion Control:

Linear bearings enable precise and accurate control over the motion of heavy loads. This precision is crucial in applications where components need to be positioned or moved with extremely fine tolerances.

- Reduced Friction:

Linear bearings are engineered to minimize friction between moving parts, even under heavy load conditions. This not only improves efficiency but also enhances the accuracy of movement.

- Smooth Movement:

Linear bearings provide smooth and consistent movement, ensuring that heavy loads can be guided and positioned without jarring or sudden stops. This is particularly important for applications requiring controlled and gentle motion.

- Reduced Wear and Maintenance:

By reducing friction and wear, linear bearings extend the operational lifespan of heavy-load equipment. This translates to lower maintenance requirements and longer intervals between servicing.

- Optimized Performance:

Linear bearings contribute to the overall performance of heavy-load systems by allowing them to operate smoothly, accurately, and reliably. This is critical in applications where precision and consistency are paramount.

- Wide Range of Industries:

Linear bearings find application in various industries, including manufacturing, aerospace, automotive, and heavy machinery, where heavy loads need to be moved with high precision.

Overall, linear bearings serve as a cornerstone in applications that demand the simultaneous management of heavy loads and precise movement. They ensure that heavy machinery and equipment can function efficiently and accurately while maintaining the safety and integrity of the entire system.

Examples of Crucial Motion Control Scenarios Using Linear Bearings

Linear bearings are crucial for achieving precise motion control in various scenarios where accuracy, repeatability, and smooth movement are essential. Here are some examples:

- 1. CNC Machining:

In computer numerical control (CNC) machines, linear bearings enable precise movement of the cutting tool or workpiece along multiple axes. This accuracy is necessary to produce complex and intricate parts with tight tolerances.

- 2. Semiconductor Manufacturing:

In semiconductor fabrication equipment, linear bearings control the movement of wafers, masks, and other components with micron-level precision. This precision is vital for creating tiny circuits and microchips.

- 3. 3D Printing:

In 3D printers, linear bearings ensure accurate positioning of the print head and build platform. This accuracy is crucial for creating intricate and detailed 3D-printed objects.

- 4. Laser Cutting and Engraving:

Linear bearings are used in laser cutting and engraving machines to control the movement of the laser head. Precise motion ensures accurate cutting and engraving on various materials.

- 5. Microscopy:

In microscopy applications, linear bearings enable precise positioning of microscope stages and objectives. This accuracy is essential for capturing detailed images and conducting precise measurements.

- 6. Metrology and Inspection:

Linear bearings are crucial in metrology and inspection equipment for accurately measuring and inspecting parts. This ensures compliance with quality standards and specifications.

- 7. Optical Systems:

In optical systems, linear bearings control the movement of lenses, mirrors, and other optical components. Precise motion is essential for maintaining accurate focus and alignment.

- 8. Coordinate Measuring Machines (CMMs):

Linear bearings in CMMs allow accurate measurement of parts’ dimensions and geometries. Precise motion ensures reliable measurement results.

- 9. Aerospace and Defense Testing:

In aerospace and defense industries, linear bearings are used in testing equipment to simulate various conditions. Accurate motion control is crucial for testing components’ performance and durability.

These examples highlight the critical role of linear bearings in achieving precise motion control across industries. Whether in manufacturing, research, or testing, linear bearings ensure accurate and repeatable movement for optimal results.

editor by CX 2024-04-12

China supplier Inch Tapered Taper Roller Bearing 55200/55437 for Bicycle Motorcycle Auto Parts and Hoist Door Shaft Kyk Bearing Linear Shaft Bearing manufacturer

Product Description

| Basic Features of Tapered Roller Bearing | |

| Types | 35710 series 30300 series 31300 series 32000 series 32200 series 32300 series 32900 series 33000 series Inch series |

| Material | Bearing Steel(GCr15, 100Cr6) 08/10 |

| Dimension | Metric and Inch |

| Precision | P0 P5 P6 |

| Super finishing | Yes |

| MOQ | 1 PC |

| Delivery Time | 30-60 days |

| Sea Ports | ZheJiang HangZhou HangZhou |

Why Choose HECTO?

1. More than 20 years of manufacturing and exporting experiences

2. an IATF16949 company

3. 100% inspecting of products

4. More competitive prices with better quality

5. More than 99% of delivery in time

6. Rapid response of your emails and questions

7. Products can be traced back

***HECTO’s prices of tapered roller bearing are very competitive. You are welcome to send us your email to get Prices List.

Some Metric Tapered Roller Bearings

| BEARING NO. | d | D | T |

| 35712 | 15 | 35 | 11.75 |

| 35713 | 17 | 40 | 13.25 |

| 35714 | 20 | 47 | 15.25 |

| 35715 | 25 | 52 | 16.25 |

| 35716 | 30 | 62 | 17.25 |

| 35717 | 35 | 72 | 18.25 |

| 35718 | 40 | 80 | 19.25 |

| 35719 | 45 | 85 | 20.75 |

| 35710 | 50 | 90 | 21.75 |

| 35711 | 55 | 100 | 22.75 |

| 35712 | 60 | 110 | 23.75 |

| 35713 | 65 | 120 | 24.75 |

| 35714 | 70 | 125 | 26.25 |

| 35715 | 75 | 130 | 27.25 |

| 35716 | 80 | 140 | 28.25 |

| 35717 | 85 | 150 | 30.5 |

| 35718 | 90 | 160 | 32.5 |

| 35719 | 95 | 170 | 34.5 |

| 35710 | 100 | 180 | 37 |

| 35711 | 105 | 190 | 39 |

| 35712 | 110 | 200 | 41 |

| 35714 | 120 | 215 | 43.5 |

| 35716 | 130 | 230 | 43.75 |

| 35718 | 140 | 250 | 45.75 |

| 35710 | 150 | 270 | 49 |

| 35712 | 160 | 290 | 52 |

| 35714 | 170 | 310 | 57 |

| 35716 | 180 | 320 | 57 |

| 35718 | 190 | 340 | 60 |

| 35710 | 200 | 360 | 64 |

| 30302 | 15 | 42 | 14.25 |

| 30303 | 17 | 47 | 15.25 |

| 30304 | 20 | 52 | 16.25 |

| 30305 | 25 | 62 | 18.25 |

| 30306 | 30 | 72 | 20.75 |

| 30307 | 35 | 80 | 22.75 |

| 30308 | 40 | 90 | 25.25 |

| 30309 | 45 | 100 | 27.25 |

| 3571 | 50 | 110 | 29.25 |

| 3571 | 55 | 120 | 31.5 |

| 3571 | 60 | 130 | 33.5 |

| 3571 | 65 | 140 | 36 |

| 3571 | 70 | 150 | 38 |

| 3571 | 75 | 160 | 40 |

| 3 0571 | 80 | 170 | 42.5 |

| 3 0571 | 85 | 180 | 44.5 |

| 3 0571 | 90 | 190 | 46.5 |

| 3571 | 95 | 200 | 49.5 |

| 30320 | 100 | 215 | 51.5 |

| 30321 | 105 | 225 | 53.5 |

| 30322 | 110 | 240 | 54.5 |

| 30324 | 120 | 260 | 59.5 |

| 30326 | 130 | 280 | 63.75 |

| 30328 | 140 | 300 | 67.75 |

| 30330 | 150 | 320 | 72 |

| 3571 | 260 | 540 | 114 |

| 31305 | 25 | 62 | 18.25 |

| 31306 | 30 | 72 | 20.75 |

| 31307 | 35 | 80 | 22.75 |

| 31308 | 40 | 90 | 25.25 |

| 31309 | 45 | 100 | 27.25 |

| 31310 | 50 | 110 | 29.25 |

| 31311 | 55 | 120 | 31.5 |

| 31312 | 60 | 130 | 33.5 |

| 31313 | 65 | 140 | 36 |

| 31314 | 70 | 150 | 38 |

| 31315 | 75 | 160 | 40 |

| 31316 | 80 | 170 | 42.5 |

| 31317 | 85 | 180 | 44.5 |

| 320/22 | 22 | 44 | 15 |

| 320/28 | 28 | 52 | 16 |

| 320/32 | 32 | 58 | 17 |

| 32004 | 20 | 42 | 15 |

| 32005 | 25 | 47 | 15 |

| 32006 | 30 | 55 | 17 |

| 32007 | 35 | 62 | 18 |

| 32008 | 40 | 68 | 19 |

| 32009 | 45 | 75 | 20 |

| 32571 | 50 | 80 | 20 |

| 32011 | 55 | 90 | 23 |

| 32012 | 60 | 95 | 23 |

| 32013 | 65 | 100 | 23 |

| 32014 | 70 | 110 | 25 |

| 32015 | 75 | 115 | 25 |

| 32016 | 80 | 125 | 29 |

| 32017 | 85 | 130 | 29 |

| 32018 | 90 | 140 | 32 |

| 32019 | 95 | 145 | 32 |

| 32571 | 100 | 150 | 32 |

| 32571 | 105 | 160 | 35 |

| 32571 | 110 | 170 | 38 |

| 32571 | 120 | 180 | 38 |

| 32026 | 130 | 200 | 45 |

| 32571 | 140 | 210 | 45 |

| 32030 | 150 | 225 | 48 |

| 32032 | 160 | 240 | 51 |

| 32034 | 170 | 260 | 57 |

| 32205 | 25 | 52 | 19.5 |

| 32206 | 30 | 62 | 21.25 |

| 32207 | 35 | 72 | 24.25 |

| 32208 | 40 | 80 | 24.75 |

| 32209 | 45 | 85 | 24.75 |

| 32210 | 50 | 90 | 24.75 |

| 32211 | 55 | 100 | 26.75 |

| 32212 | 60 | 110 | 29.75 |

| 32213 | 65 | 120 | 32.75 |

| 32214 | 70 | 125 | 33.25 |

| 32215 | 75 | 130 | 33.25 |

| 32216 | 80 | 140 | 35.25 |

| 32217 | 85 | 150 | 38.5 |

| 32218 | 90 | 160 | 42.5 |

| 32219 | 95 | 170 | 45.5 |

| 32220 | 100 | 180 | 49 |

| 32221 | 105 | 190 | 53 |

| 32222 | 110 | 200 | 56 |

| 32224 | 120 | 215 | 61.5 |

| 32226 | 130 | 230 | 67.75 |

| 32228 | 140 | 250 | 71.75 |

| 32230 | 150 | 270 | 77 |

| 32232 | 160 | 290 | 84 |

| 32234 | 170 | 310 | 91 |

| 32236 | 180 | 320 | 91 |

| 32238 | 190 | 340 | 97 |

| 32240 | 200 | 360 | 104 |

| 32244 | 220 | 400 | 114 |

| 32303 | 17 | 47 | 20.25 |

| 32304 | 20 | 52 | 22.25 |

| 32305 | 25 | 62 | 25.25 |

| 32306 | 30 | 72 | 28.75 |

| 32307 | 35 | 80 | 32.75 |

| 32308 | 40 | 90 | 35.25 |

| 32309 | 45 | 100 | 38.25 |

| 32310 | 50 | 110 | 42.25 |

| 32311 | 55 | 120 | 45.5 |

| 32312 | 60 | 130 | 48.5 |

| 32313 | 65 | 140 | 51 |

| 32314 | 70 | 150 | 54 |

| 32315 | 75 | 160 | 58 |

| 32316 | 80 | 170 | 61.5 |

| 32317 | 85 | 180 | 63.5 |

| 32318 | 90 | 190 | 67.5 |

| 32319 | 95 | 200 | 71.5 |

| 32320 | 100 | 215 | 77.5 |

| 32321 | 105 | 225 | 81.5 |

| 32322 | 110 | 240 | 84.5 |

| 32324 | 120 | 260 | 90.5 |

| 32330 | 150 | 320 | 114 |

| 32907 | 35 | 55 | 14 |

| 32908 | 40 | 62 | 15 |

| 32909 | 45 | 68 | 15 |

| 32910 | 50 | 72 | 15 |

| 32911 | 55 | 80 | 17 |

| 32912 | 60 | 85 | 17 |

| 32913 | 65 | 90 | 17 |

| 32914 | 70 | 100 | 20 |

| 32915 | 75 | 105 | 20 |

| 32916 | 80 | 110 | 20 |

| 33005 | 25 | 47 | 17 |

| 33006 | 30 | 55 | 20 |

| 33007 | 35 | 62 | 21 |

| 33008 | 40 | 68 | 22 |

| 33009 | 45 | 75 | 24 |

| 33571 | 50 | 80 | 24 |

| 33011 | 55 | 90 | 27 |

| 33012 | 60 | 95 | 27 |

| 33013 | 65 | 100 | 27 |

| 33014 | 70 | 110 | 31 |

| 33017 | 85 | 130 | 36 |

| 33018 | 90 | 140 | 39 |

| 33113 | 65 | 110 | 34 |

| 33116 | 80 | 130 | 37 |

| 33117 | 85 | 140 | 41 |

| 33119 | 95 | 160 | 49 |

| 332/28 | 28 | 58 | 24 |

| 332/32 | 32 | 65 | 26 |

| 33206 | 30 | 62 | 25 |

| 33207 | 35 | 72 | 28 |

| 33208 | 40 | 80 | 32 |

| 33209 | 45 | 85 | 32 |

| 33210 | 50 | 90 | 32 |

| 33212 | 60 | 110 | 38 |

Some Inch Tapered Roller Bearings

| BEARING NO. | d | D | T |

| L21549/L21511 | 15.875 | 34.988 | 10.998 |

| 11590/11520 | 15.875 | 42.862 | 14.288 |

| H11590/H11520 | 15.875 | 42.863 | 14.288 |

| A6067/A6157 | 16.993 | 39.992 | 12.014 |

| LM11749/LM11710 | 17.462 | 39.878 | 13.843 |

| HLM11749/HLM11710 | 17.463 | 39.878 | 13.843 |

| A6075/A6157 | 19.05 | 39.992 | 12.014 |

| HLM11949/HLM11910 | 19.05 | 45.237 | 15.494 |

| LM11949/LM11910 | 19.05 | 45.237 | 15.494 |

| 5075/5185 | 19.05 | 47 | 14.381 |

| H 0571 7/H5715 | 19.05 | 49.225 | 18.034 |

| 9067/9195 | 19.05 | 49.225 | 18.034 |

| 9067/9196 | 19.05 | 49.225 | 21.209 |

| 9067/9194 | 19.05 | 49.225 | 21.209 |

| 9078/9195 | 19.05 | 49.225 | 19.845 |

| 9078/9196 | 19.05 | 49.225 | 23.02 |

| 9078/9194 | 19.05 | 49.225 | 23.02 |

| 9074/9195 | 19.05 | 49.225 | 19.845 |

| 9074/9196 | 19.05 | 49.225 | 23.02 |

| 9074/9194 | 19.05 | 49.225 | 23.02 |

| 5079/5185 | 19.987 | 47 | 14.381 |

| 12580/12520 | 20.638 | 49.225 | 19.845 |

| HM12649/HM12610 | 21.43 | 50.005 | 17.526 |

| M12649/M12610 | 21.43 | 50.005 | 17.526 |

| HLM12749/HLM12710 | 22 | 45.237 | 15.494 |

| LM12749/LM12710 | 22 | 45.237 | 15.494 |

| HLM12749/HLM12711 | 22 | 45.975 | 15.494 |

| 7087/7196 | 22.225 | 50.005 | 13.495 |

| M12648/M12610 | 22.225 | 50.005 | 17.526 |

| 7087/7204 | 22.225 | 51.994 | 15.011 |

| 1380/1328 | 22.225 | 52.388 | 19.368 |

| H1380/H1328 | 22.225 | 52.388 | 19.368 |

| H1280/H1220 | 22.225 | 57.15 | 22.225 |

| 1779/1729 | 23.812 | 56.896 | 19.368 |

| 7098/7196 | 24.981 | 50.005 | 13.495 |

| 7098/7204 | 24.981 | 51.994 | 15.011 |

| 7097/7196 | 25 | 50.005 | 13.495 |

| 7097/7204 | 25 | 51.994 | 15.011 |

| 7100/7196 | 25.4 | 50.005 | 13.495 |

| HL44643/HL44610 | 25.4 | 50.292 | 14.224 |

| L44643/L44610 | 25.4 | 50.292 | 14.224 |

| 7100/7204 | 25.4 | 51.994 | 15.011 |

| 15101/15245 | 25.4 | 62 | 19.05 |

| 15100/15245 | 25.4 | 62 | 19.05 |

| 15101/15250 | 25.4 | 63.5 | 20.638 |

| 15101/15250X | 25.4 | 63.5 | 20.638 |

| 15100/15250 | 25.4 | 63.5 | 19.05 |

| 15100/15250X | 25.4 | 63.5 | 20.638 |

| 23100/23256 | 25.4 | 65.088 | 22.225 |

| L44649/L44610 | 26.988 | 50.292 | 14.224 |

| 15580/15520 | 26.988 | 51.15 | 17.462 |

| 15106/15245 | 26.988 | 62 | 19.05 |

| H1988/H1922 | 28.575 | 57.15 | 19.845 |

| H57174/H57120 | 28.575 | 68.263 | 22.225 |

| 2872/2820 | 28.575 | 73.571 | 22.225 |

| H57172/H57120 | 28.575 | 73.571 | 22.225 |

| 17118/17244 | 29.985 | 62 | 16.002 |

| 15117/15245 | 30 | 62 | 19.05 |

| 15117/15250 | 30 | 63.5 | 20.638 |

| 15117/15250X | 30 | 63.5 | 20.638 |

| H14118/H14283 | 30 | 72.085 | 22.385 |

| M86649/M86610 | 30.162 | 64.292 | 21.433 |

| HM86649/HM86610 | 30.163 | 64.292 | 21.433 |

| 15120/15245 | 30.213 | 62 | 19.05 |

| 15118/15245 | 30.213 | 62 | 19.05 |

| 15120/15250X | 30.213 | 63.5 | 20.638 |

| 15120/15250 | 30.213 | 63.5 | 20.638 |

| 15118/15250X | 30.213 | 63.5 | 20.638 |

| 15118/15250 | 30.213 | 63.5 | 20.638 |

| LM67048/LM67571 | 31.75 | 59.131 | 15.875 |

| H15123/H15245 | 31.75 | 61.999 | 18.161 |

| 15123/15245 | 31.75 | 62 | 18.161 |

| 15126/15245 | 31.75 | 62 | 19.05 |

| 15125/15245 | 31.75 | 62 | 19.05 |

| 15123/15250 | 31.75 | 63.5 | 20.638 |

| 15123/15250X | 31.75 | 63.5 | 20.638 |

| 15126/15250 | 31.75 | 63.5 | 20.638 |

| 15126/15250X | 31.75 | 63.5 | 20.638 |

| 15125/15250 | 31.75 | 63.5 | 20.638 |

| 15125/15250X | 31.75 | 63.5 | 20.638 |

| H2580/H2520 | 31.75 | 66.421 | 25.4 |

| H57175/H57120 | 31.75 | 68.263 | 22.225 |

| 14125A/14276 | 31.75 | 69.012 | 19.845 |

| 14125A/14274 | 31.75 | 69.012 | 19.845 |

| 2580/2523 | 31.75 | 69.85 | 23.812 |

| H2580/H2523 | 31.75 | 69.85 | 23.813 |

| M88048/M88571 | 33.338 | 68.262 | 22.225 |

| HM88048/HM88571 | 33.338 | 68.263 | 22.225 |

| H14131/H14276 | 33.338 | 69.012 | 19.845 |

| 14130/14276 | 33.338 | 69.012 | 19.845 |

| 14130/14274 | 33.338 | 69.012 | 19.845 |

| LM48548/LM48510 | 34.925 | 65.088 | 18.034 |

| 14137A/14276 | 34.925 | 69.012 | 19.845 |

| 14137A/14274 | 34.925 | 69.012 | 19.845 |

| 14138A/14276 | 34.925 | 69.012 | 19.845 |

| 14138A/14274 | 34.925 | 69.012 | 19.845 |

| H14138A/H14276 | 34.925 | 69.012 | 19.845 |

| HHM88649/HHM88610 | 34.925 | 72.233 | 25.4 |

| 25877/25821 | 34.925 | 73.571 | 23.812 |

| H25877R/H25821 | 34.925 | 73.571 | 23.813 |

| 31594/31520 | 34.925 | 76.2 | 29.37 |

| H31593/H31520 | 34.925 | 76.2 | 29.37 |

| 3379/3320 | 34.925 | 80.167 | 29.37 |

| HL68149/HL68110 | 34.987 | 59.131 | 15.875 |

| HL68149/HL68111 | 34.987 | 59.975 | 15.875 |

| L68149/L68110 | 35 | 59.131 | 15.875 |

| 25880/25821 | 36.487 | 73.571 | 23.812 |

| 13682/13620 | 36.512 | 69.012 | 19.05 |

| HM89449/HM89410 | 36.512 | 76.2 | 29.37 |

| 3878/3820 | 36.512 | 85.725 | 30.162 |

| 46143/46368 | 36.513 | 93.663 | 31.75 |

| HJL69349/HJL69310 | 38 | 63 | 17 |

| 13889/13830 | 38.1 | 63.5 | 12.7 |

| LM29749/LM29710 | 38.1 | 65.088 | 18.034 |

| HLM29749/HLM29710 | 38.1 | 65.088 | 18.034 |

| HLM29748/HLM29710 | 38.1 | 65.088 | 18.034 |

| 13685/13621 | 38.1 | 69.012 | 19.05 |

| 2788/2729 | 38.1 | 76.2 | 23.812 |

| 2788/2720 | 38.1 | 76.2 | 23.812 |

| H2788R/H2720 | 38.1 | 76.2 | 23.813 |

| H26878R/H26822 | 38.1 | 79.375 | 23.813 |

| 3490/3420 | 38.1 | 79.375 | 29.37 |

| 3381/3320 | 38.1 | 80.167 | 29.37 |

| 418/414 | 38.1 | 88.501 | 26.988 |

| 2789/2735X | 39.688 | 73.571 | 23.812 |

| M257147/M257111 | 39.688 | 73.571 | 25.654 |

| H2789R/H2720 | 39.688 | 76.2 | 23.813 |

| HLM300849/HLM300811 | 40.987 | 67.975 | 17.5 |

| 18590/18520 | 41.275 | 73.571 | 16.667 |

| H18590/H18520 | 41.275 | 73.571 | 16.667 |

| LM501349/LM501310 | 41.275 | 73.431 | 19.558 |

| HLM501349/HLM501310 | 41.275 | 73.431 | 19.558 |

| HLM501349/HLM501314 | 41.275 | 73.431 | 21.43 |

| 11162R/11300 | 41.275 | 76.2 | 18.009 |

| 24780/24720 | 41.275 | 76.2 | 22.225 |

| 24780R/24721 | 41.275 | 76.2 | 25.4 |

| 26882/26822 | 41.275 | 79.375 | 23.812 |

| H26882R/H26820 | 41.275 | 80.167 | 25.4 |

| 3384/3320 | 41.275 | 80.167 | 29.37 |

| 3585R/3525 | 41.275 | 87.313 | 30.163 |

| 4388/4335 | 41.275 | 90.488 | 39.688 |

| 3579R/3525 | 42.863 | 87.313 | 30.163 |

| 342S/332 | 42.875 | 80 | 21 |

| 25577/25520 | 42.875 | 82.931 | 23.812 |

| 25577/25523 | 42.875 | 82.931 | 26.988 |

| H25577/H25523 | 42.875 | 82.931 | 26.988 |

| 25577/25521 | 42.875 | 83.058 | 23.812 |

| 25580/25520 | 44.45 | 82.931 | 23.812 |

| H25580/H25520 | 44.45 | 82.931 | 23.813 |

| 25580/25523 | 44.45 | 82.931 | 26.988 |

| 25580/25521 | 44.45 | 83.058 | 23.812 |

| 3578/3525 | 44.45 | 87.312 | 30.162 |

| 3578R/3525 | 44.45 | 87.313 | 30.163 |

| HM85719/HM85710 | 44.45 | 88.9 | 30.163 |

| 355X/352 | 44.45 | 90.119 | 23 |

| HM85719/HM85712 | 44.45 | 92.075 | 30.163 |

| 3782/3720 | 44.45 | 93.264 | 30.163 |

| HM903249/HM903210 | 44.45 | 95.25 | 30.958 |

| 53176/53375 | 44.45 | 95.25 | 30.958 |

| 55175/55443 | 44.45 | 112.713 | 30.163 |

| 65385/65320 | 44.45 | 114.3 | 44.45 |

| 3776/3720 | 44.983 | 93.264 | 30.163 |

| LM157149/LM157110 | 45.242 | 73.431 | 19.558 |

| HLM157149/HLM157110 | 45.242 | 73.431 | 19.558 |

| LM603049/LM6571 | 45.242 | 77.788 | 19.842 |

| LM603049/LM603012 | 45.242 | 77.788 | 21.43 |

| 25590/25520 | 45.618 | 82.931 | 23.812 |

| H25590/H25520 | 45.618 | 82.931 | 23.813 |

| 25590/25523 | 45.618 | 82.931 | 26.988 |

| H25590/H25523 | 45.618 | 82.931 | 26.988 |

| H25590/18620 | 46.038 | 79.375 | 17.463 |