Product Description

Single row cylindrical roller bearings usually only bear radial force. Compared with ball bearings of the same size, the radial bearing capacity is increased by 1.5-3 times, with good rigidity and impact resistance. It is especially suitable for rigid supported shafts, short shafts, shafts with axial displacement caused by thermal elongation, and machine accessories requiring separate bearings for installation and disassembly. It is mainly used for large motors, machine tool spindles, front and rear engine support shafts, train and bus trunk shaft support, diesel engine crankshaft, automobile and tractor gearbox, etc.

| Designation | Size | dynamic | static | Reference speed | Limiting speed | ||

| d[mm] | D[mm] | B[mm] | C[kN] | C0[kN] | [r/min] | [r/min] | |

| NU 2209 ECJ | 45 | 85 | 23 | 85 | 81.5 | 9 000 | 9 500 |

| NU 2209 ECP | 45 | 85 | 23 | 85 | 81.5 | 9 000 | 9 500 |

| NU 2209 ECPH | 45 | 85 | 23 | 85 | 81.5 | 9 000 | 9 500 |

| NU 2309 ECML | 45 | 100 | 36 | 160 | 153 | 7 500 | 13 000 |

| NU 2309 ECP | 45 | 100 | 36 | 160 | 153 | 7 500 | 8 500 |

| NU 309 ECJ | 45 | 100 | 25 | 112 | 100 | 7 500 | 8 500 |

| NU 309 ECM | 45 | 100 | 25 | 112 | 100 | 7 500 | 8 500 |

| NU 309 ECML | 45 | 100 | 25 | 112 | 100 | 7 500 | 13 000 |

| NU 309 ECP | 45 | 100 | 25 | 112 | 100 | 7 500 | 8 500 |

| NU 309 ECPH | 45 | 100 | 25 | 112 | 100 | 7 500 | 8 500 |

| NUP 209 ECJ | 45 | 85 | 19 | 69.5 | 64 | 9 000 | 9 500 |

| NUP 209 ECM | 45 | 85 | 19 | 69.5 | 64 | 9 000 | 9 500 |

| NUP 209 ECML | 45 | 85 | 19 | 69.5 | 64 | 9 000 | 1 5000 |

| NUP 209 ECP | 45 | 85 | 19 | 69.5 | 64 | 9 000 | 9 500 |

| NUP 209 ECPH | 45 | 85 | 19 | 69.5 | 64 | 9 000 | 9 500 |

| NUP 2209 ECP | 45 | 85 | 23 | 85 | 81.5 | 9 000 | 9 500 |

| NUP 2309 ECML | 45 | 100 | 36 | 160 | 153 | 7 500 | 13 000 |

| NUP 2309 ECP | 45 | 100 | 36 | 160 | 153 | 7 500 | 8 500 |

| NUP 309 ECJ | 45 | 100 | 25 | 112 | 100 | 7 500 | 8 500 |

| NUP 309 ECML | 45 | 100 | 25 | 106 | 91.5 | 7 500 | 13 000 |

| NUP 309 ECNP | 45 | 100 | 25 | 112 | 100 | 7 500 | 8 500 |

| NUP 309 ECP | 45 | 100 | 25 | 112 | 100 | 7 500 | 8 500 |

| N 210 ECP | 50 | 90 | 20 | 73.5 | 69.5 | 8 500 | 9 000 |

| N 310 ECP | 50 | 110 | 27 | 127 | 112 | 6 700 | 8 000 |

| NJ 210 ECJ | 50 | 90 | 20 | 73.5 | 69.5 | 8 500 | 9 000 |

| NJ 210 ECM | 50 | 90 | 20 | 73.5 | 69.5 | 8 500 | 9 000 |

| NJ 210 ECML | 50 | 90 | 20 | 73.5 | 69.5 | 8 500 | 14 000 |

| NJ 210 ECP | 50 | 90 | 20 | 73.5 | 69.5 | 8 500 | 9 000 |

| NJ 210 ECPH | 50 | 90 | 20 | 73.5 | 69.5 | 8 500 | 9 000 |

| NJ 2210 ECJ | 50 | 90 | 23 | 90 | 88 | 8 500 | 9 000 |

About us

ZheJiang REET BEARING.CO.,LTD is a professional bearing manufacturer and exporter.

We have a wealth of technical.All producing processes are finished in our manufactory. As an ISO9001:2000 certified manufacturer,we will solve various problems in application and use of our bearings.

Our company is an authorized distributor of FAG, INA, CZPT and other world brand bearings.Our company has the right to self-export bearings and launches its own brand RTB.

Our bearing had been exported to more than 20 countries worldwide and are warmly welcomed.

We’re looking forward to your order.

FAQ

1.Is the company a production factory or a trading company?

ZheJiang REET BEARING CO.,LTD is a manufacturing enterprise focusing on bearings and integrating research, production and sales.

2.How many the MOQ of your company?

Depending on the size of the bearing, the MOQ is variable, if you are interested, you can contact me for a quote.

3.Does the company accept OEM or customized bearings?

In addition to standard products, we also supply non-standard and modified standard products for special application. Meanwhile, we provide OEM service.

4.Can the company provide free samples?

We can provide samples for free. You only need to provide shipping.

5.What are the company’s delivery terms?

We can accept EXW,FOB,CFR,CIF,etc. You can choose the 1 which is the most convenient cost effective for you.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Small and Medium-Sized (60-115mm) |

| Material: | Bearing Steel |

| Spherical: | Non-Aligning Bearings |

| Load Direction: | Radial Bearing |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

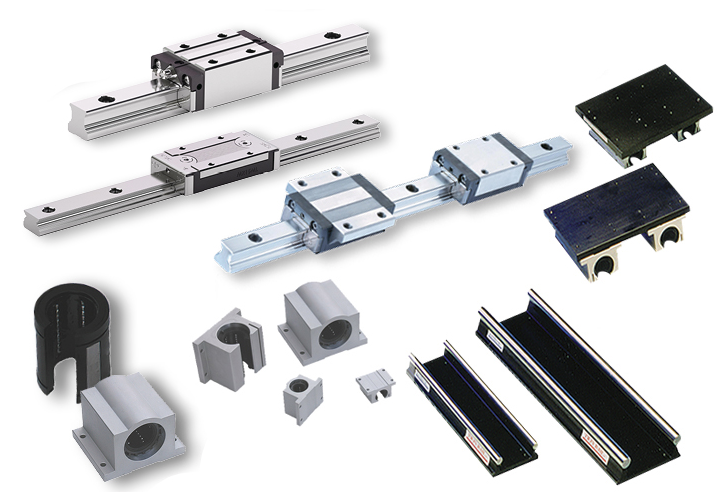

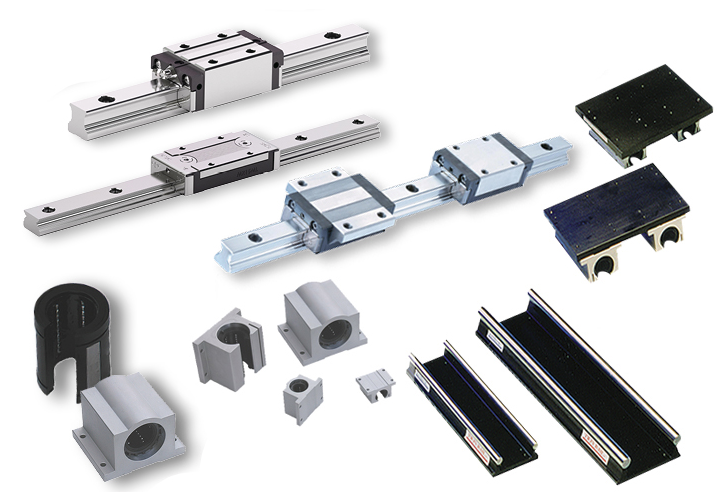

Differences Between Linear Ball Bearings and Linear Roller Bearings

Linear ball bearings and linear roller bearings are two distinct types of linear bearings, each with its own design and characteristics. Here’s how they differ and when they are preferred:

- 1. Design:

Linear ball bearings use ball bearings to provide rolling motion along the shaft. Linear roller bearings, on the other hand, use cylindrical or needle rollers for motion. Roller bearings have a larger contact area, distributing the load over a broader surface.

- 2. Load Capacity:

Linear roller bearings typically have a higher load-carrying capacity compared to linear ball bearings. This makes them suitable for applications with heavier loads and greater force requirements.

- 3. Friction and Smoothness:

Linear ball bearings offer lower friction and smoother motion due to the point contact between the balls and the shaft. Roller bearings may have slightly higher friction but can handle larger loads without sacrificing smoothness.

- 4. Precision and Accuracy:

Linear ball bearings are often preferred for applications requiring high precision and accuracy. Their point contact provides precise positioning and repeatability, making them suitable for tasks like CNC machining and optical systems.

- 5. Noise and Vibration:

Linear ball bearings tend to generate less noise and vibration due to their smoother rolling action. Roller bearings may produce slightly more noise but are still used in applications where noise is not a critical factor.

- 6. Speed:

Linear ball bearings are well-suited for high-speed applications due to their low friction and smooth motion. Roller bearings are also capable of high speeds but may have slightly different characteristics.

- 7. Cost:

Linear ball bearings are often more cost-effective for lower-load and precision applications. Linear roller bearings may be preferred for heavy-duty applications, which may justify their higher cost.

- 8. Application Scenarios:

Linear ball bearings are commonly used in applications where precision, smooth motion, and accuracy are paramount, such as in CNC machinery, 3D printers, and optical systems. Linear roller bearings excel in applications with higher loads, such as heavy machinery, material handling, and industrial automation.

In summary, the choice between linear ball bearings and linear roller bearings depends on the specific requirements of the application. Each type has its strengths and weaknesses, and selecting the right type ensures optimal performance and longevity.

Recent Advancements in Linear Bearing Technology

Recent years have seen significant advancements in linear bearing technology, leading to improved performance, reliability, and versatility. Some notable developments include:

- Nanotechnology: The integration of nanotechnology has allowed for the development of ultra-precision linear bearings with nanometer-scale accuracy. These bearings are ideal for applications requiring extremely fine movement and positioning.

- Smart Bearings: Advances in sensor technology have enabled the creation of smart linear bearings that can monitor parameters like temperature, load, and vibration in real time. This data helps in predictive maintenance and optimizing operational efficiency.

- Materials Innovation: New materials with enhanced properties, such as self-lubricating and corrosion-resistant coatings, have extended the lifespan of linear bearings and reduced the need for frequent lubrication and maintenance.

- Compact Designs: Manufacturers are designing more compact linear bearings to suit space-constrained applications while maintaining high load capacity and precision.

- Environmental Sustainability: There’s a growing emphasis on developing linear bearings with reduced environmental impact, including using eco-friendly materials and designs that require less energy to operate.

- Integration of IoT: Linear bearings are being integrated into the Internet of Things (IoT) networks, allowing them to communicate with other equipment and systems for seamless automation and optimization.

- Magnetic Levitation Bearings: Magnetic levitation (maglev) technology is being applied to linear bearings to create frictionless movement, reducing wear and enabling smoother and more precise motion.

- Advanced Coatings: Coatings with enhanced wear resistance, low friction, and improved thermal properties are being applied to linear bearings, extending their service life in challenging environments.

These advancements have contributed to the expanding range of applications where linear bearings can be used, from aerospace and automotive industries to medical devices and consumer electronics. As technology continues to evolve, linear bearings will play a crucial role in enabling more efficient and precise motion control across various sectors.

Design Principles and Functionalities of Linear Bearings

Linear bearings are designed with specific principles to facilitate controlled linear motion along a single axis. These design principles contribute to their functionalities, making them essential components in various applications:

- Rolling Elements:

Linear bearings typically feature rolling elements, such as balls or rollers, that move along a track or rail. These rolling elements reduce friction and enable smooth linear motion.

- Guiding Mechanism:

Linear bearings incorporate a guiding mechanism to constrain the motion to a single axis. This guiding mechanism ensures that the linear bearing moves precisely along the desired path.

- Load Distribution:

The design of linear bearings allows for effective distribution of loads, both in the radial and axial directions. This load distribution ensures stability and prevents excessive stress on individual components.

- Rail or Track:

Linear bearings typically run along a rail or track that provides a smooth and accurate path for the rolling elements. The rail is designed to resist wear and maintain its precision over time.

- Cage or Carriage:

Linear bearings use a cage or carriage to house the rolling elements and maintain their proper spacing. This arrangement ensures even load distribution and smooth movement.

- Sealing and Lubrication:

Linear bearings often incorporate sealing mechanisms to protect the rolling elements from contaminants and to retain lubrication. Proper lubrication ensures smooth motion and extends the bearing’s lifespan.

- Mounting Options:

Linear bearings are designed to be mounted in various ways, depending on the application’s requirements. Mounting options include flange-mounted, base-mounted, or end-supported configurations.

- Adjustability:

Many linear bearings are designed with provisions for adjustment, allowing users to fine-tune the preload or clearance to optimize performance and minimize play.

- Materials:

Linear bearings are constructed from materials that offer high wear resistance, durability, and corrosion resistance. Common materials include steel, stainless steel, and various engineering plastics.

- Accessories:

Accessories such as end caps, seals, and lubrication systems can enhance the functionality and lifespan of linear bearings by providing protection and ensuring proper maintenance.

Functionalities of linear bearings include providing precise linear motion, guiding components along a defined path, minimizing friction, distributing loads, and maintaining stability. The design principles ensure reliable operation and make linear bearings indispensable in applications requiring controlled and accurate linear motion.

editor by CX 2024-05-15

China best Bearing Manufacturers High-Speed Linear Bearings Motorcycle Accessories Automation Equipment Bearings Lm20luu Lm25luu Lm30luu Linear Bearing connecting rod bearing

Product Description

Linear bearing is a linear motion system used for linear stroke and cylindrical shaft.

Because the bearing ball and the bearing jacket are point contact, the steel ball rolls with small friction resistance, so the linear bearing has small friction and relatively stable characteristics, does not change with the bearing speed, and can obtain a stable linear movement with high sensitivity and high precision.

| Product Name | Linear bearing |

| Brand Name | KSA |

| Material | Gcr15 |

| Precision Grade | P0,P6,P5 |

| Certification | ISO 9001 |

| Packeage | Box /Carton/Wooden Box/Plastic Tube or Per buyers requirement |

| MOQ | Depending On Moedl |

| Serice | OEM |

| Sample | Available |

| Payment | TT or L/C or Western Union |

| Port | HangZhou ZheJiang HangZhou |

Product Description

Company Profile

ZheJiang Kangshi Precision Bearing Manufacturing Co., Ltd., located in Yandian Town Industrial Park, HangZhou City, ZheJiang Province, mainly produces zero deep groove ball bearings, 2 types of cylindrical roller bearings, 3 types of aligning roller bearings, 6 types of angular contact ball bearings, 7 types of tapered roller bearings, 8 types of thrust ball bearings, thrust bearings, 9 types of thrust aligning roller bearings, outer spherical bearings, auto parts, Motorcycle parts and other rolling bearings. Our factory has strong professional technology, good production equipment and perfect testing means, can fully meet the various types, specifications, high precision and special use requirements of bearing products customized processing, the production process of the product according to the strict national standards of enterprise internal control standards for the implementation of full inspection and multi-project comprehensive inspection of factory products, Can ensure the quality of each set of factory bearing products to meet national standards. Kangshi bearing has always implemented national standards, market prices, and implemented the “three guarantees” principle for customers: To ensure high-quality quality, preferential prices, superior after-sales service! Welcome customers at home and abroad to consult and negotiate business, the company will continue to win the trust of more customers with good product quality and reputation.

Our certificate

Scope of application

Used in electronic equipment, printing machinery, tobacco machinery, medical machinery, textile machinery, food processing machinery, packaging machinery, robots, power tools, CNC machine tools, automobiles and digital three-dimensional coordinate measuring equipment and other precision equipment or special machinery industry.

durable Heat treatment technology Keep clean

With high-end technology manufacturing, After advanced quenching heat treatment, Even tiny dust that is invisible to the

each product has high hardness and high the bearing has enough hardness to ensure naked eye can have adverse effects,

quality of its own performance the load carrying capacity so keep your surroundings clean

FAQ

Q: What is the MOQ?

A: It depends on the bearing type. You can send inquiry or send e-mail for more information.

Q: How about the package?

A: Industrial packing in general condition (Plastic drums/boxes/industrial packaging + cartons + pallets). Accept design package when OEM.

Q: How long is the delivery time?

A: It will take about 10 to 40 days, depends on the model and quantity.

Q:What are the advantages of your company’s services compared to other companies?

A: Factory direct supply, price advantage, 24 hours online timely reply, Provide customers with customs clearance

and quality of various documents, 100% after-sales service

Q:OEM POLICY

A:We can printing your brand (logo,artwork)on the bearings or laser engraving your brand on the bearings.

We can custom your packaging according to your design All copyright own by clients and we promised don’t

disclose any info.

Q:How to contact us quickly?

A:Please send us an inquiry or message and leave your other contact information, such as phone number,

account or account, we will contact you as soon as possible and provide the detailed information

you need.

Please feel free to contact us, if you have any other question

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Low Temperature, Corrosion Resistant, High Temperature, High Speed |

|---|---|

| Function: | Super |

| Flange Shape: | Oval |

| Samples: |

US$ 2/Set

1 Set(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Challenges and Solutions for Addressing Friction and Wear in Linear Bearings

Friction and wear are common challenges in linear bearings that can impact their performance and lifespan. Here are the challenges and some solutions to address them:

- 1. Challenge: Friction:

Friction between the bearing components can lead to increased energy consumption, heat generation, and reduced efficiency.

- Solution: Lubrication:

Proper lubrication is essential to minimize friction. Lubricants reduce the contact between moving parts, allowing smoother motion and reducing wear. Choosing the right lubricant and applying it correctly can significantly mitigate friction-related issues.

- 2. Challenge: Wear:

Continuous movement can lead to wear on the bearing surfaces, affecting precision and performance over time.

- Solution: Regular Maintenance:

Implementing a regular maintenance schedule can help monitor wear and replace worn components before they compromise performance. This includes cleaning, re-lubrication, and periodic inspection of the bearing’s condition.

- 3. Challenge: Contaminants:

Dust, debris, and foreign particles can enter the bearing system, leading to increased friction and accelerated wear.

- Solution: Sealing and Protection:

Using seals, covers, or protective enclosures can help prevent contaminants from entering the bearing system. These protective measures maintain the integrity of the lubricant and extend the bearing’s lifespan.

- 4. Challenge: Improper Installation:

If linear bearings are not installed correctly, misalignment and uneven load distribution can contribute to friction and wear.

- Solution: Precise Installation:

Follow manufacturer guidelines for proper installation, ensuring accurate alignment and even load distribution. This reduces the risk of premature wear and ensures optimal performance.

- 5. Challenge: Inadequate Lubrication:

If the linear bearings are under-lubricated or over-lubricated, it can lead to increased friction and wear.

- Solution: Lubrication Management:

Monitor and manage lubrication levels to ensure they are within the recommended range. Regularly assess the lubricant’s condition and replenish as needed to maintain optimal performance.

- 6. Challenge: High Loads and Speeds:

High loads and speeds can increase friction and wear on linear bearings.

- Solution: Proper Selection:

Select linear bearings that are designed to handle the specific loads and speeds of the application. This ensures that the bearings can operate effectively under the given conditions.

Addressing friction and wear challenges in linear bearings requires a combination of proper maintenance practices, appropriate lubrication, protective measures, and careful selection of bearings. By implementing these solutions, the performance and longevity of linear bearings can be optimized.

Managing Contamination and Debris in Linear Bearings

Contamination and debris pose significant challenges to the proper functioning of linear bearings. However, various measures are employed to effectively manage these issues:

- Preventive Sealing:

Linear bearings are often equipped with protective seals that act as barriers against contaminants. These seals prevent dust, dirt, and other particles from entering the bearing housing, thus reducing the risk of contamination.

- Shielding:

Linear bearings can incorporate shields that offer an additional layer of protection against debris. Shields are designed to keep larger particles away from the bearing’s rolling elements, enhancing the bearing’s longevity.

- Wipers and Scrapers:

Some linear bearings feature wipers or scrapers that actively remove debris from the bearing’s moving parts. These components help prevent the accumulation of contaminants that could compromise performance.

- Regular Maintenance:

Periodic inspection and cleaning are crucial to maintaining the cleanliness of linear bearings. Routine maintenance procedures help identify and remove any foreign particles that may have entered the bearing housing.

- Clean Environment:

Creating a clean operating environment is essential. In applications where contamination is a concern, steps are taken to minimize the presence of dust, dirt, and other pollutants in the vicinity of the linear bearings.

- Proper Lubrication:

Lubrication not only reduces friction but also creates a barrier against contaminants. The lubricant can help prevent particles from adhering to bearing surfaces, facilitating their removal during maintenance.

- Regular Inspections:

Frequent visual inspections can help identify early signs of contamination. Timely detection allows for prompt cleaning and maintenance, preventing further damage.

- Appropriate Sealing Materials:

Using high-quality sealing materials that are resistant to wear and tear is essential. The right materials can effectively keep contaminants out while withstanding the operating conditions.

- Choosing Suitable Environment:

Where possible, placing linear bearings in environments with lower levels of contamination or installing additional protective measures can help manage debris-related challenges.

By implementing these strategies, engineers and operators can effectively manage the challenges associated with contamination and debris, ensuring the optimal performance and longevity of linear bearings.

Design Principles and Functionalities of Linear Bearings

Linear bearings are designed with specific principles to facilitate controlled linear motion along a single axis. These design principles contribute to their functionalities, making them essential components in various applications:

- Rolling Elements:

Linear bearings typically feature rolling elements, such as balls or rollers, that move along a track or rail. These rolling elements reduce friction and enable smooth linear motion.

- Guiding Mechanism:

Linear bearings incorporate a guiding mechanism to constrain the motion to a single axis. This guiding mechanism ensures that the linear bearing moves precisely along the desired path.

- Load Distribution:

The design of linear bearings allows for effective distribution of loads, both in the radial and axial directions. This load distribution ensures stability and prevents excessive stress on individual components.

- Rail or Track:

Linear bearings typically run along a rail or track that provides a smooth and accurate path for the rolling elements. The rail is designed to resist wear and maintain its precision over time.

- Cage or Carriage:

Linear bearings use a cage or carriage to house the rolling elements and maintain their proper spacing. This arrangement ensures even load distribution and smooth movement.

- Sealing and Lubrication:

Linear bearings often incorporate sealing mechanisms to protect the rolling elements from contaminants and to retain lubrication. Proper lubrication ensures smooth motion and extends the bearing’s lifespan.

- Mounting Options:

Linear bearings are designed to be mounted in various ways, depending on the application’s requirements. Mounting options include flange-mounted, base-mounted, or end-supported configurations.

- Adjustability:

Many linear bearings are designed with provisions for adjustment, allowing users to fine-tune the preload or clearance to optimize performance and minimize play.

- Materials:

Linear bearings are constructed from materials that offer high wear resistance, durability, and corrosion resistance. Common materials include steel, stainless steel, and various engineering plastics.

- Accessories:

Accessories such as end caps, seals, and lubrication systems can enhance the functionality and lifespan of linear bearings by providing protection and ensuring proper maintenance.

Functionalities of linear bearings include providing precise linear motion, guiding components along a defined path, minimizing friction, distributing loads, and maintaining stability. The design principles ensure reliable operation and make linear bearings indispensable in applications requiring controlled and accurate linear motion.

editor by CX 2024-05-07

China Good quality Car Accessories/Motorcycle Parts/Distributor/Ball/Wheel/Deep Groove Ball/Auto/Roller/Pillow Block/Needle Roller/Linear/Ceramic/One Way/Slewing Bearing 6016 connecting rod bearing

Product Description

The rings and balls of all-ceramic deep groove ball bearings are made of silicon nitride (Si3N4) ceramic material. This bearing can be designed as a full ball or with PTFE, PEEK or stainless steel 304/316 cage. PTFE is the default standard cage.

Full ceramic deep groove ball bearings have the characteristics of non-magnetic and electrical insulation, wear-resistant and corrosion-resistant, oil-free and self-lubricating, high temperature and cold resistance, and can be used in extremely harsh environments and special working conditions. It can be used in high temperature environment above 400ºC under the condition of full ball or equipped with stainless steel 316 cage. The PEEK cage can also be used at temperatures above 250°C. For CZPT temperatures (for example, lower than -70°C), full ceramic bearings with PTFE cages or stainless steel 316 cages can be used. Normally, the normal radial clearance is C0. When it is necessary to adapt to the extreme environment, other clearances can be customized.

| open | size(mm) | Installation size (mm) | weight | weight | ||||||

| model | Inner diameter | Outer diameter | Thickness | Chamfer | da | da | Da | ra | Si3N4 | ZrO2 |

| d | D | B | r(min) | min | max | max | max | (kg) | (kg) | |

| 683 | 3 | 7 | 2 | 0.1 | / | 0.00013 | 0.00571 | |||

| 693 | 8 | 3 | 0.15 | / | 0.00571 | 0.0005 | ||||

| 603 | 9 | 3 | 0.15 | / | 0.0004 | 0.0007 | ||||

| 623 | 10 | 4 | 0.15 | / | 0.0007 | 0.0013 | ||||

| 633 | 13 | 5 | 0.15 | / | 0.0014 | 0.0571 | ||||

| 684 | 4 | 9 | 2.5 | 0.1 | 4.8 | / | 8.2 | 0.1 | 0.0003 | 0.0005 |

| 694 | 11 | 4 | 0.15 | 5.2 | / | 9.8 | 0.15 | 0.0007 | 0.0013 | |

| 604 | 12 | 4 | 0.2 | 5.6 | / | 10.4 | 0.2 | 0.0009 | 0.0017 | |

| 624 | 13 | 5 | 0.2 | 5.6 | / | 11.4 | 0.2 | 0.0013 | 0.571 | |

| 634 | 16 | 5 | 0.3 | 6 | / | 14 | 0.3 | 0.0571 | 0.004 | |

| 685 | 5 | 11 | 3 | 0.15 | 6.2 | / | 9.8 | 0.15 | 0.0005 | 0.0009 |

| 695 | 13 | 4 | 0.2 | 6.6 | / | 11.4 | 0.2 | 0.001 | 0.0019 | |

| 605 | 14 | 5 | 0.2 | 6.6 | / | 12.4 | 0.2 | 0.0015 | 0.0571 | |

| 625 | 16 | 5 | 0.3 | 7 | / | 14 | 0.3 | 0.0571 | 0.0038 | |

| 635 | 19 | 6 | 0.3 | 7 | / | 17 | 0.3 | 0.0036 | 0.0066 | |

| 686 | 6 | 13 | 3.5 | 0.15 | 7.2 | / | 11.8 | 0.15 | 0.0008 | 0.0015 |

| 696 | 15 | 5 | 0.2 | 7.6 | / | 13.4 | 0.2 | 0.0016 | 0.003 | |

| 606 | 17 | 6 | 0.3 | 8 | / | 15 | 0.3 | 0.0571 | 0.0046 | |

| 626 | 19 | 6 | 0.3 | 8 | / | 17 | 0.3 | 0.0034 | 0.0063 | |

| 636 | 22 | 7 | 0.3 | 8 | / | 20 | 0.3 | 0.0058 | 0.5718 | |

| 687 | 7 | 14 | 3.5 | 0.15 | 8.2 | / | 12.8 | 0.15 | 0.0009 | 0.0017 |

| 697 | 17 | 5 | 0.3 | 9 | / | 15 | 0.3 | 0.0571 | 0.004 | |

| 607 | 19 | 6 | 0.3 | 9 | / | 17 | 0.3 | 0.0032 | 0.0059 | |

| 627 | 22 | 7 | 0.3 | 9 | / | 20 | 0.3 | 0.0053 | 0.0098 | |

| 637 | 26 | 9 | 0.3 | 9 | / | 24 | 0.3 | 0.01 | 0.0185 | |

| 688 | 8 | 16 | 4 | 0.2 | 9.6 | / | 14.4 | 0.2 | 0.0014 | 0.0571 |

| 698 | 19 | 6 | 0.3 | 10 | / | 17 | 0.3 | 0.003 | 0.0056 | |

| 608 | 22 | 7 | 0.3 | 10 | / | 20 | 0.3 | 0.005 | 0.0093 | |

| 628 | 24 | 8 | 0.3 | 10 | / | 22 | 0.3 | 0.0072 | 0.013 | |

| 638 | 28 | 9 | 0.3 | 10 | / | 26 | 0.3 | 0.012 | 0.571 | |

| 689 | 9 | 17 | 4 | 0.2 | 10.6 | / | 15.4 | 0.2 | 0.0015 | 0.0571 |

| 699 | 20 | 6 | 0.3 | 11 | / | 18 | 0.3 | 0.0035 | 0.0065 | |

| 609 | 24 | 7 | 0.3 | 11 | / | 22 | 0.3 | 0.006 | 0.011 | |

| 629 | 26 | 8 | 0.3 | 11 | / | 24 | 0.3 | 0.0081 | 0.015 | |

| 639 | 30 | 10 | 0.6 | 13 | / | 26 | 0.6 | 0.015 | 0.571 | |

| 6800 | 10 | 19 | 5 | 0.3 | 12 | 12 | 17 | 0.3 | 0.0571 | 0.004 |

| 6900 | 22 | 6 | 0.3 | 12 | 12.5 | 20 | 0.3 | 0.0038 | 0.007 | |

| 6000 | 26 | 8 | 0.3 | 12 | 13 | 24 | 0.3 | 0.0075 | 0.014 | |

| 6200 | 30 | 9 | 0.6 | 14 | 16 | 26 | 0.6 | 0.013 | 0.571 | |

| 6300 | 35 | 11 | 0.6 | 14 | 16.5 | 31 | 0.6 | 0.571 | 0.04 | |

| 6801 | 12 | 21 | 5 | 0.3 | 14 | 14 | 19 | 0.3 | 0.0571 | 0.005 |

| 6901 | 24 | 6 | 0.3 | 14 | 14.5 | 22 | 0.3 | 0.0042 | 0.008 | |

| 16001 | 28 | 7 | 0.3 | 14 | / | 26 | 0.3 | 0.0079 | 0.015 | |

| 6001 | 28 | 8 | 0.3 | 14 | 15.5 | 26 | 0.3 | 0.0092 | 0.017 | |

| 6201 | 32 | 10 | 0.6 | 16 | 17 | 28 | 0.6 | 0.015 | 0.571 | |

| 6301 | 37 | 12 | 1 | 17 | 18 | 32 | 1 | 0.571 | 0.046 | |

| 6802 | 15 | 24 | 5 | 0.3 | 17 | 17 | 22 | 0.3 | 0.571 | 0.005 |

| 6902 | 28 | 7 | 0.3 | 17 | 17 | 26 | 0.3 | 0.0063 | 0.012 | |

| 16002 | 32 | 8 | 0.3 | 17 | / | 30 | 0.3 | 0.011 | 0.571 | |

| 6002 | 32 | 9 | 0.3 | 17 | 19 | 30 | 0.3 | 0.013 | 0.571 | |

| 6202 | 35 | 11 | 0.6 | 19 | 20.5 | 31 | 0.3 | 0.019 | 0.035 | |

| 6302 | 42 | 13 | 1 | 20 | 22.5 | 37 | 1 | 0.035 | 0.064 | |

| 6803 | 17 | 26 | 5 | 0.3 | 19 | 19 | 24 | 0.3 | 0.571 | 0.005 |

| 6903 | 30 | 7 | 0.3 | 19 | 19.5 | 28 | 0.3 | 0.0071 | 0.013 | |

| 16003 | 35 | 8 | 0.3 | 19 | / | 33 | 0.3 | 0.014 | 0.571 | |

| 6003 | 35 | 10 | 0.3 | 19 | 21.5 | 33 | 0.3 | 0.017 | 0.032 | |

| 6203 | 40 | 12 | 0.6 | 21 | 23.5 | 36 | 0.6 | 0.571 | 0.052 | |

| 6303 | 47 | 14 | 1 | 22 | 25.5 | 42 | 1 | 0.047 | 0.087 | |

| 6403 | 62 | 17 | 1.1 | 23.5 | / | 55.5 | 1 | 0.11 | 0.21 | |

| 6804 | 20 | 32 | 7 | 0.3 | 22 | 22.5 | 30 | 0.3 | 0.007 | 0.013 |

| 6904 | 37 | 9 | 0.3 | 22 | 24 | 35 | 0.3 | 0.015 | 0.571 | |

| 16004 | 42 | 8 | 0.3 | 22 | / | 40 | 0.3 | 0.02 | 0.037 | |

| 6004 | 42 | 12 | 0.6 | 24 | 25.5 | 38 | 0.6 | 0.571 | 0.052 | |

| 6204 | 47 | 14 | 1 | 25 | 26.5 | 42 | 1 | 0.045 | 0.082 | |

| 6304 | 52 | 15 | 1.1 | 26.5 | 28 | 45.5 | 1 | 0.06 | 0.11 | |

| 6404 | 72 | 19 | 1.1 | 26.5 | / | 65.5 | 1 | 0.17 | 0.31 | |

| 6805 | 25 | 37 | 7 | 0.3 | 27 | 27 | 35 | 0.3 | 0.009 | 0.016 |

| 6905 | 42 | 9 | 0.3 | 27 | 28.5 | 40 | 0.3 | 0.018 | 0.032 | |

| 16005 | 47 | 8 | 0.3 | 27 | / | 45 | 0.3 | 0.571 | 0.045 | |

| 6005 | 47 | 12 | 0.6 | 29 | 30 | 43 | 0.6 | 0.033 | 0.061 | |

| 6205 | 52 | 15 | 1 | 30 | 32 | 47 | 1 | 0.054 | 0.099 | |

| 6305 | 62 | 17 | 1.1 | 31.5 | 36 | 55.5 | 1 | 0.098 | 0.18 | |

| 6405 | 80 | 21 | 1.5 | 33 | / | 72 | 1.5 | 0.22 | 0.41 | |

| 6806 | 30 | 42 | 7 | 0.3 | 32 | 32 | 50 | 1 | 0.01 | 0.018 |

| 6906 | 47 | 9 | 0.3 | 32 | 34 | 57 | 1 | 0.571 | 0.04 | |

| 16006 | 55 | 9 | 0.3 | 32 | 42.5 | 65.5 | 1 | 0.036 | 0.067 | |

| 6006 | 55 | 13 | 1 | 35 | 36.5 | 53 | 1 | 0.048 | 0.089 | |

| 6206 | 62 | 16 | 1 | 35 | 38.5 | 60 | 1 | 0.083 | 0.15 | |

| 6306 | 72 | 19 | 1.1 | 36.5 | 42.5 | 68.5 | 1 | 0.14 | 0.27 | |

| 6406 | 90 | 23 | 1.5 | 54 | / | 82 | 2 | 0.31 | 0.57 | |

| 6807 | 35 | 47 | 7 | 0.3 | 37 | 37 | 45 | 0.3 | 0.011 | 0.571 |

| 6907 | 55 | 10 | 0.6 | 39 | 39 | 51 | 0.6 | 0.031 | 0.058 | |

| 16007 | 62 | 9 | 0.3 | 37 | / | 60 | 0.3 | 0.045 | 0.082 | |

| 6007 | 62 | 14 | 1 | 40 | 41.5 | 57 | 1 | 0.063 | 0.12 | |

| 6207 | 72 | 17 | 1.1 | 41.5 | 44.5 | 65.5 | 1 | 0.12 | 0.22 | |

| 6307 | 80 | 21 | 1.5 | 43 | 47 | 72 | 1.5 | 0.19 | 0.36 | |

| 6407 | 100 | 25 | 1.5 | 43 | / | 92 | 1.5 | 0.4 | 0.73 | |

| 6808 | 40 | 52 | 7 | 0.3 | 42 | 42 | 50 | 0.3 | 0.013 | 0.02 |

| 6908 | 62 | 12 | 0.6 | 44 | 46 | 58 | 0.6 | 0.05 | 0.09 | |

| 16008 | 68 | 9 | 0.3 | 42 | / | 66 | 0.3 | 0.05 | 0.1 | |

| 6008 | 68 | 15 | 1 | 45 | 47.5 | 63 | 1 | 0.08 | 0.15 | |

| 6208 | 80 | 18 | 1.1 | 46.5 | 50.5 | 73.5 | 1 | 0.15 | 0.28 | |

| 6308 | 90 | 23 | 1.5 | 48 | 53 | 80 | 1.5 | 0.27 | 0.49 | |

| 6408 | 110 | 27 | 2 | 49 | / | 101 | 2 | 0.513 | 0.946 | |

| 6809 | 45 | 58 | 7 | 0.3 | 47 | 47.5 | 56 | 0.3 | 0.016 | 0.571 |

| 6909 | 68 | 12 | 0.6 | 49 | 50 | 64 | 0.6 | 0.053 | 0.097 | |

| 16009 | 75 | 10 | 0.6 | 49 | / | 71 | 0.6 | 0.07 | 0.13 | |

| 6009 | 75 | 16 | 1 | 50 | 53.5 | 70 | 1 | 0.1 | 0.19 | |

| 6209 | 85 | 19 | 1.1 | 51.5 | 55.5 | 78.5 | 1 | 0.175 | 0.32 | |

| 6309 | 100 | 25 | 1.5 | 53 | 61.5 | 92 | 1.5 | 0.345 | 0.64 | |

| 6409 | 120 | 29 | 2 | 54 | / | 111 | 2 | 0.64 | 1.18 | |

| 6810 | 50 | 65 | 7 | 0.3 | 52 | 52.5 | 63 | 0.3 | 0.571 | 0.038 |

| 6910 | 72 | 12 | 0.6 | 54 | 55 | 68 | 0.6 | 0.06 | 0.1 | |

| 16571 | 80 | 10 | 0.6 | 54 | / | 76 | 0.6 | 0.07 | 0.13 | |

| 6571 | 80 | 16 | 1 | 55 | 58.5 | 75 | 1 | 0.11 | 0.2 | |

| 6210 | 90 | 20 | 1.1 | 56.5 | 60 | 83.2 | 1 | 0.19 | 0.35 | |

| 6310 | 110 | 27 | 2 | 59 | 68 | 101 | 2 | 0.44 | 0.82 | |

| 6410 | 130 | 31 | 2.1 | 61 | / | 119 | 2 | 0.78 | 1.45 | |

| 6811 | 55 | 72 | 9 | 0.3 | 57 | 59 | 70 | 0.3 | 0.03 | 0.06 |

| 6911 | 80 | 13 | 1 | 60 | 61.5 | 75 | 1 | 0.08 | 0.15 | |

| 16011 | 90 | 11 | 0.6 | 59 | / | 86 | 0.6 | 0.11 | 0.2 | |

| 6011 | 90 | 18 | 1.1 | 61.5 | 64 | 83.5 | 1 | 0.16 | 0.29 | |

| 6211 | 100 | 21 | 1.5 | 63 | 66.5 | 92 | 1.5 | 0.26 | 0.48 | |

| 6311 | 120 | 29 | 2 | 64 | 72.5 | 111 | 2 | 0.57 | 1.05 | |

| 6411 | 140 | 33 | 2.1 | 66 | / | 129 | 2 | 0.95 | 1.76 | |

| 6812 | 60 | 78 | 10 | 0.3 | 62 | 64 | 76 | 0.3 | 0.04 | 0.08 |

| 6912 | 85 | 13 | 1 | 65 | 66 | 80 | 1 | 0.08 | 0.15 | |

| 16012 | 95 | 11 | 0.6 | 64 | / | 91 | 0.6 | 0.12 | 0.22 | |

| 6012 | 95 | 18 | 1.1 | 66.5 | 69 | 88.5 | 1 | 0.17 | 0.32 | |

| 6212 | 110 | 22 | 1.5 | 68 | 74.5 | 102 | 1.5 | 0.33 | 0.6 | |

| 6312 | 130 | 31 | 2.1 | 71 | 79 | 119 | 2 | 0.72 | 1.32 | |

| 6412 | 150 | 35 | 2.1 | 71 | 139 | 2 | 1.15 | 2.13 | ||

| 6813 | 65 | 85 | 10 | 0.6 | 69 | 69 | 81 | 0.6 | 0.05 | 0.1 |

| 6913 | 90 | 13 | 1 | 70 | 71.5 | 85 | 1 | 0.09 | 0.17 | |

| 16013 | 100 | 11 | 0.6 | 69 | / | 96 | 0.6 | 0.13 | 0.23 | |

| 6013 | 100 | 18 | 1.1 | 71.5 | 73 | 93.5 | 1 | 0.18 | 0.34 | |

| 6213 | 120 | 23 | 1.5 | 73 | 80 | 112 | 1.5 | 0.42 | 0.77 | |

| 6313 | 140 | 33 | 2.1 | 76 | 85.5 | 129 | 2 | 0.88 | 1.62 | |

| 6814 | 70 | 90 | 10 | 0.6 | 74 | 74.5 | 86 | 0.6 | 0.056 | 0.1 |

| 6914 | 100 | 16 | 1 | 75 | 77.5 | 95 | 1 | 0.15 | 0.27 | |

| 16014 | 110 | 13 | 0.6 | 74 | / | 106 | 0.6 | 0.18 | 0.34 | |

| 6014 | 110 | 20 | 1.1 | 76.5 | 80.5 | 103.5 | 1 | 0.25 | 0.47 | |

| 6214 | 125 | 24 | 1.5 | 78 | 84 | 117 | 1.5 | 0.45 | 0.84 | |

| 6314 | 150 | 35 | 2.1 | 81 | 92 | 139 | 2 | 1.07 | 1.98 | |

| 6815 | 75 | 95 | 10 | 0.6 | 79 | 79.5 | 91 | 0.6 | 0.06 | 0.11 |

| 6915 | 105 | 16 | 1 | 80 | 82 | 100 | 1 | 0.15 | 0.28 | |

| 16015 | 115 | 13 | 0.6 | 79 | / | 111 | 0.6 | 0.19 | 0.36 | |

| 6015 | 115 | 20 | 1.1 | 81.5 | 85.5 | 108.5 | 1 | 0.27 | 0.5 | |

| 6215 | 130 | 25 | 1.5 | 83 | 90 | 122 | 1.5 | 0.5 | 0.92 | |

| 6816 | 80 | 100 | 10 | 0.6 | 84 | 84.5 | 96 | 0.6 | 0.063 | 0.12 |

| 6916 | 110 | 16 | 1 | 85 | 87.5 | 105 | 1 | 0.16 | 0.3 | |

| 16016 | 125 | 14 | 0.6 | 84 | / | 121 | 0.6 | 0.26 | 0.48 | |

| 6016 | 125 | 22 | 1.1 | 86.5 | 91 | 118.5 | 1 | 0.36 | 0.67 | |

| 6216 | 140 | 26 | 2 | 89 | 95.5 | 131 | 2 | 0.59 | 1.09 | |

| 6817 | 85 | 110 | 13 | 1 | 90 | 90.5 | 105 | 1 | 0.11 | 0.2 |

| 6917 | 120 | 18 | 1.1 | 91.5 | 94.5 | 113.5 | 1 | 0.23 | 0.42 | |

| 16017 | 130 | 14 | 0.6 | 89 | / | 126 | 0.6 | 0.27 | 0.5 | |

| 6017 | 130 | 22 | 1.1 | 91.5 | 96 | 123.5 | 1 | 0.38 | 0.71 | |

| 6217 | 150 | 28 | 2 | 94 | 102 | 141 | 2 | 0.73 | 1.35 | |

| 6818 | 90 | 115 | 13 | 1 | 95 | 95.5 | 110 | 1 | 0.12 | 0.21 |

| 6918 | 125 | 18 | 1.1 | 96.5 | 98.5 | 118.5 | 1 | 0.24 | 0.45 | |

| 16018 | 140 | 16 | 1 | 95 | / | 135 | 1 | 0.36 | 0.67 | |

| 6018 | 140 | 24 | 1.5 | 98 | 103 | 132 | 1.5 | 0.5 | 0.92 | |

| 6819 | 95 | 120 | 13 | 1 | 100 | 102 | 115 | 1 | 0.12 | 0.23 |

| 6919 | 130 | 18 | 1.1 | 101.5 | 104 | 123.5 | 1 | 0.25 | 0.46 | |

| 16019 | 145 | 16 | 1 | 100 | / | 140 | 1 | 0.38 | 0.7 | |

| 6019 | 145 | 24 | 1.5 | 103 | 109 | 137 | 1.5 | 0.51 | 0.95 | |

| 6820 | 100 | 125 | 13 | 1 | 105 | 106 | 120 | 1 | 0.13 | 0.24 |

| 6920 | 140 | 20 | 1.1 | 106.5 | 111 | 133.5 | 1 | 0.35 | 0.64 | |

| 16571 | 150 | 16 | 1 | 105 | / | 145 | 1 | 0.39 | 0.73 | |

| 6571 | 150 | 24 | 1.5 | 108 | 113 | 142 | 1.5 | 0.54 | 0.99 | |

| 6821 | 105 | 130 | 13 | 1 | 110 | 111 | 125 | 1 | 0.14 | 0.25 |

| 6921 | 145 | 20 | 1.1 | 111.5 | 116 | 138.5 | 1 | 0.36 | 0.66 | |

| 6822 | 110 | 140 | 16 | 1 | 115 | 117 | 135 | 1 | 0.21 | 0.38 |

| 6922 | 150 | 20 | 1.1 | 116.5 | 121 | 143.5 | 1 | 0.37 | 0.69 | |

| 6824 | 120 | 150 | 16 | 1 | 125 | 127 | 145 | 1 | 0.22 | 0.41 |

About us

ZheJiang REET BEARING.CO.,LTD is a professional bearing manufacturer and exporter.

We have a wealth of technical.All producing processes are finished in our manufactory. As an ISO9001:2000 certified manufacturer,we will solve various problems in application and use of our bearings.

Our company is an authorized distributor of FAG, INA, CZPT and other world brand bearings.Our company has the right to self-export bearings and launches its own brand RTB.

Our bearing had been exported to more than 20 countries worldwide and are warmly welcomed.

We are looking forward to your order.

FAQ

1.Is the company a production factory or a trading company?

ZheJiang REET BEARING CO.,LTD is a manufacturing enterprise focusing on bearings and integrating research, production and sales.

2.How many the MOQ of your company?

Depending on the size of the bearing, the MOQ is variable, if you are interested, you can contact me for a quote.

3.Does the company accept OEM or customized bearings?

In addition to standard products, we also supply non-standard and modified standard products for special application. Meanwhile, we provide OEM service.

4.Can the company provide free samples?

We can provide samples for free. You only need to provide shipping.

5.What are the company’s delivery terms?

We can accept EXW,FOB,CFR,CIF,etc. You can choose the 1 which is the most convenient cost effective for you.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 15° |

|---|---|

| Aligning: | Aligning Bearing |

| Separated: | Separated |

| Rows Number: | Single |

| Load Direction: | Radial Bearing |

| Material: | Ceramic |

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Differences between Open-Type and Closed-Type Linear Bearings

Open-type and closed-type linear bearings are two common variations used in linear motion systems, each with its own advantages and considerations:

- 1. Open-Type Linear Bearings:

Open-type linear bearings, as the name suggests, have an open design that allows easy access to the bearing’s rolling elements and raceways. These bearings are characterized by:

- Quick Maintenance: Open-type bearings are easier to clean, lubricate, and inspect due to their open structure, making maintenance more convenient.

- Increased Contamination Risk: Because they are exposed, open-type bearings are more susceptible to dust, debris, and contamination, which can affect their performance and lifespan.

- 2. Closed-Type Linear Bearings:

Closed-type linear bearings are enclosed within a housing or carriage that provides protection from external elements. These bearings offer the following features:

- Enhanced Contamination Protection: Closed-type bearings are less vulnerable to contaminants and offer improved protection against dust, dirt, and debris, leading to longer service life.

- Reduced Accessibility: Maintenance and inspection of closed-type bearings might be more complex due to the need to disassemble the housing or carriage for access.

- Reduced Noise: The enclosed design of closed-type bearings can contribute to reduced noise levels, which is advantageous in noise-sensitive applications.

Choosing between open-type and closed-type linear bearings depends on the specific requirements of the application. If easy maintenance and accessibility are crucial, open-type bearings might be preferred. On the other hand, closed-type bearings offer better protection against contaminants and reduced noise, making them suitable for environments where cleanliness and quiet operation are essential.

Managing Contamination and Debris in Linear Bearings

Contamination and debris pose significant challenges to the proper functioning of linear bearings. However, various measures are employed to effectively manage these issues:

- Preventive Sealing:

Linear bearings are often equipped with protective seals that act as barriers against contaminants. These seals prevent dust, dirt, and other particles from entering the bearing housing, thus reducing the risk of contamination.

- Shielding:

Linear bearings can incorporate shields that offer an additional layer of protection against debris. Shields are designed to keep larger particles away from the bearing’s rolling elements, enhancing the bearing’s longevity.

- Wipers and Scrapers:

Some linear bearings feature wipers or scrapers that actively remove debris from the bearing’s moving parts. These components help prevent the accumulation of contaminants that could compromise performance.

- Regular Maintenance:

Periodic inspection and cleaning are crucial to maintaining the cleanliness of linear bearings. Routine maintenance procedures help identify and remove any foreign particles that may have entered the bearing housing.

- Clean Environment:

Creating a clean operating environment is essential. In applications where contamination is a concern, steps are taken to minimize the presence of dust, dirt, and other pollutants in the vicinity of the linear bearings.

- Proper Lubrication:

Lubrication not only reduces friction but also creates a barrier against contaminants. The lubricant can help prevent particles from adhering to bearing surfaces, facilitating their removal during maintenance.

- Regular Inspections:

Frequent visual inspections can help identify early signs of contamination. Timely detection allows for prompt cleaning and maintenance, preventing further damage.

- Appropriate Sealing Materials:

Using high-quality sealing materials that are resistant to wear and tear is essential. The right materials can effectively keep contaminants out while withstanding the operating conditions.

- Choosing Suitable Environment:

Where possible, placing linear bearings in environments with lower levels of contamination or installing additional protective measures can help manage debris-related challenges.

By implementing these strategies, engineers and operators can effectively manage the challenges associated with contamination and debris, ensuring the optimal performance and longevity of linear bearings.

Common Applications and Industries for Linear Bearings

Linear bearings find widespread use in a variety of applications and industries due to their ability to provide controlled linear motion. Some common applications and industries where linear bearings are essential components include:

- Industrial Automation:

Linear bearings are used in automated machinery and equipment to enable precise and repeatable movement of components. They play a critical role in assembly lines, material handling systems, and robotics.

- CNC Machinery:

In computer numerical control (CNC) machines, linear bearings facilitate accurate movement of the cutting tool or workpiece. They contribute to the precision and quality of machining operations.

- Medical Devices:

Linear bearings are crucial in medical equipment such as MRI machines, CT scanners, and robotic surgical systems. Their precision and smooth motion are vital for accurate medical procedures.

- Packaging Machinery:

In packaging and labeling machines, linear bearings ensure precise movement of containers, products, and labeling mechanisms. This results in consistent and reliable packaging processes.

- Printing Industry:

Linear bearings are used in printing presses to ensure precise movement of print heads, paper feed mechanisms, and other critical components. This helps achieve accurate printing results.

- Textile Machinery:

In textile manufacturing, linear bearings contribute to the smooth operation of spinning machines, looms, and fabric handling systems. They help maintain proper tension and alignment of materials.

- Aerospace and Defense:

Linear bearings are utilized in aerospace applications such as aircraft actuators, landing gear systems, and satellite mechanisms. They withstand harsh conditions and provide reliable motion control.

- Material Handling:

In conveyor systems and material handling equipment, linear bearings facilitate the movement of goods along production lines, warehouses, and distribution centers.

- Automotive Industry:

Linear bearings are used in automotive manufacturing for tasks like seat adjustments, sunroof operation, and door mechanisms. Their precision enhances passenger comfort.

- Scientific Research:

In laboratory equipment and scientific instruments, linear bearings contribute to accurate positioning of samples, sensors, and analytical components.

These are just a few examples of the diverse applications and industries where linear bearings are essential. Their ability to provide controlled and reliable linear motion makes them indispensable in achieving precision, efficiency, and performance across various sectors.

editor by CX 2024-04-26

China best Ceramic Bearing Rod End Cylindrical Roller Turbocharger Hub Wheel Wheel Connecting Rod Housing Plastic Linear Stainless Steel Spherical Bearing manufacturer

Product Description

Ceramic Bearing Rod End Cylindrical Roller Turbocharger Hub Wheel Wheel Connecting Rod Housing Plastic Linear Stainless Steel Spherical Bearing

Application of Ceramic Bearing

Ceramic bearings are used in a wide variety of applications, including:

- Aerospace: Ceramic bearings are used in aerospace applications, such as jet engines and spacecraft, because they are lightweight, strong, and corrosion-resistant.

- Automotive: Ceramic bearings are used in automotive applications, such as high-performance engines and transmissions, because they can withstand high temperatures and loads.

- Machine tools: Ceramic bearings are used in machine tools, such as lathes and milling machines, because they can operate at high speeds and provide precise positioning.

- Medical: Ceramic bearings are used in medical applications, such as artificial joints and pacemakers, because they are biocompatible and non-magnetic.

- Other: Ceramic bearings are also used in a variety of other applications, such as wind turbines, robotics, and industrial equipment.

Ceramic bearings offer a number of advantages over traditional metal bearings, including:

- Lightweight: Ceramic bearings are much lighter than metal bearings, which can save weight and improve fuel efficiency in automotive and aerospace applications.

- Strong: Ceramic bearings are much stronger than metal bearings, which can withstand higher loads and temperatures.

- Corrosion-resistant: Ceramic bearings are resistant to corrosion, which can extend their lifespan and reduce maintenance costs.

- Low friction: Ceramic bearings have lower friction than metal bearings, which can improve efficiency and reduce wear.

- Non-magnetic: Ceramic bearings are non-magnetic, which makes them ideal for use in applications where there is a risk of interference with magnetic fields, such as medical devices and MRI machines.

Overall, ceramic bearings offer a number of advantages over traditional metal bearings, making them a good choice for a wide variety of applications.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Small and Medium-Sized (60-115mm) |

| Material: | Bearing Steel |

| Spherical: | Aligning Bearings |

| Load Direction: | Axial Bearing |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Signs of Wear or Damage in Linear Bearings and Maintenance

Identifying signs of wear or damage in linear bearings is essential for maintaining their performance and preventing costly failures. Here are common signs of wear and damage and how to address them:

- 1. Increased Friction:

If you notice increased resistance during linear motion, it could indicate that the bearing components are wearing out. This can lead to reduced efficiency and accuracy.

- Solution: Regular Lubrication:

Ensure proper lubrication of the bearings to minimize friction and prevent premature wear. Follow manufacturer recommendations for lubrication intervals and types.

- 2. Uneven Movement:

If the linear motion becomes uneven, jerky, or experiences sudden stops, it may be due to damaged bearing components.

- Solution: Inspection and Replacement:

Inspect the bearings and associated components for any signs of damage, such as dents or cracks. Replace any damaged parts to restore smooth motion.

- 3. Abnormal Noise:

Unusual noises during linear motion, such as grinding or clicking sounds, can indicate friction and wear within the bearings.

- Solution: Lubrication and Inspection:

Lubricate the bearings as recommended and inspect for any foreign particles or debris that might be causing the noise. Clean and replace components if necessary.

- 4. Increased Play or Clearance:

If there is noticeable play or excessive clearance in the linear system, it can affect precision and lead to inaccuracies.

- Solution: Adjustment or Replacement:

Check for loose bolts, misalignment, or worn components causing the play. Make necessary adjustments or replace worn parts to restore proper fit and function.

- 5. Reduced Performance:

If your linear system is no longer achieving the desired accuracy or performance, it could be due to worn bearings.

- Solution: Maintenance and Replacement:

Regularly perform maintenance tasks, such as cleaning, lubrication, and inspection. If performance does not improve, consider replacing the bearings with new ones.

- 6. Visible Damage:

Any visible signs of physical damage, such as deformation, corrosion, or cracks, require immediate attention.

- Solution: Replacement:

If the damage is severe, replace the damaged bearings promptly to avoid further issues.

Regular maintenance practices, including proper lubrication, cleaning, and inspection, are crucial for preventing wear and damage in linear bearings. Addressing any signs of wear early can extend the lifespan of the bearings and ensure consistent performance in various applications.

Managing Contamination and Debris in Linear Bearings

Contamination and debris pose significant challenges to the proper functioning of linear bearings. However, various measures are employed to effectively manage these issues:

- Preventive Sealing:

Linear bearings are often equipped with protective seals that act as barriers against contaminants. These seals prevent dust, dirt, and other particles from entering the bearing housing, thus reducing the risk of contamination.

- Shielding:

Linear bearings can incorporate shields that offer an additional layer of protection against debris. Shields are designed to keep larger particles away from the bearing’s rolling elements, enhancing the bearing’s longevity.

- Wipers and Scrapers:

Some linear bearings feature wipers or scrapers that actively remove debris from the bearing’s moving parts. These components help prevent the accumulation of contaminants that could compromise performance.

- Regular Maintenance:

Periodic inspection and cleaning are crucial to maintaining the cleanliness of linear bearings. Routine maintenance procedures help identify and remove any foreign particles that may have entered the bearing housing.

- Clean Environment:

Creating a clean operating environment is essential. In applications where contamination is a concern, steps are taken to minimize the presence of dust, dirt, and other pollutants in the vicinity of the linear bearings.

- Proper Lubrication:

Lubrication not only reduces friction but also creates a barrier against contaminants. The lubricant can help prevent particles from adhering to bearing surfaces, facilitating their removal during maintenance.

- Regular Inspections:

Frequent visual inspections can help identify early signs of contamination. Timely detection allows for prompt cleaning and maintenance, preventing further damage.

- Appropriate Sealing Materials:

Using high-quality sealing materials that are resistant to wear and tear is essential. The right materials can effectively keep contaminants out while withstanding the operating conditions.

- Choosing Suitable Environment:

Where possible, placing linear bearings in environments with lower levels of contamination or installing additional protective measures can help manage debris-related challenges.

By implementing these strategies, engineers and operators can effectively manage the challenges associated with contamination and debris, ensuring the optimal performance and longevity of linear bearings.

Common Applications and Industries for Linear Bearings

Linear bearings find widespread use in a variety of applications and industries due to their ability to provide controlled linear motion. Some common applications and industries where linear bearings are essential components include:

- Industrial Automation:

Linear bearings are used in automated machinery and equipment to enable precise and repeatable movement of components. They play a critical role in assembly lines, material handling systems, and robotics.

- CNC Machinery:

In computer numerical control (CNC) machines, linear bearings facilitate accurate movement of the cutting tool or workpiece. They contribute to the precision and quality of machining operations.

- Medical Devices:

Linear bearings are crucial in medical equipment such as MRI machines, CT scanners, and robotic surgical systems. Their precision and smooth motion are vital for accurate medical procedures.

- Packaging Machinery:

In packaging and labeling machines, linear bearings ensure precise movement of containers, products, and labeling mechanisms. This results in consistent and reliable packaging processes.

- Printing Industry:

Linear bearings are used in printing presses to ensure precise movement of print heads, paper feed mechanisms, and other critical components. This helps achieve accurate printing results.

- Textile Machinery:

In textile manufacturing, linear bearings contribute to the smooth operation of spinning machines, looms, and fabric handling systems. They help maintain proper tension and alignment of materials.

- Aerospace and Defense:

Linear bearings are utilized in aerospace applications such as aircraft actuators, landing gear systems, and satellite mechanisms. They withstand harsh conditions and provide reliable motion control.

- Material Handling:

In conveyor systems and material handling equipment, linear bearings facilitate the movement of goods along production lines, warehouses, and distribution centers.

- Automotive Industry:

Linear bearings are used in automotive manufacturing for tasks like seat adjustments, sunroof operation, and door mechanisms. Their precision enhances passenger comfort.

- Scientific Research:

In laboratory equipment and scientific instruments, linear bearings contribute to accurate positioning of samples, sensors, and analytical components.

These are just a few examples of the diverse applications and industries where linear bearings are essential. Their ability to provide controlled and reliable linear motion makes them indispensable in achieving precision, efficiency, and performance across various sectors.

editor by CX 2024-04-11

China Good quality Precision Instrument Cylindrical Roller Bearing CNC Machining Stainless Steel Linear Bearing Wheel Hub Bearing connecting rod bearing

Product Description

Product Description

Product Description:

| Type | • Single Row Four Point Contact Ball Slewing Bearing • Single Row Crossed Cylindrical Roller Slewing Bearings • Double Row Ball Slewing Bearings •Double Row Roller/Ball Combination Slewing Bearing •Three-Row Roller Slew Ring Bearing |

| Rolling elements | Steel ball / Cylinder Roller |

| Rolling elements Material | GCr5/GCr15SiMn/Customized |

| Bearing Material | 50Mn/42CrMo/42CrMo4V /Stainless Steel,Alu,Customized |

| Cage Material | Nylon 1571/ Steel /Brass |

| Structure | Taper pin , Mounting holes,Inner ring ,Grease fitting,Load plug, Seals , Roller ,Spacer Balls or separators |

| Outer diameter | 50-10000mm |

| Bore size | 50-10000mm |

| Mounting hole | Through Hole/Tapped hole/Counterbore |

| Raceway hardness | 55-62HRC |

| Inner and outer ring modulation hardness |

229-269HB/Customized |

| Gear type | No gear ,Internal gear , External gear. |

| Embellish grease | EP2 lithium lubricating grease |

| Certificate | ABS.BV,DNV,ISO9001,GL,3.1,3.2 |

| Application area | Ladle turret,Stacker crane,Bucket wheel machine,Solar heliostat Tracking System,port crane, Cabling machine,tower crane , off shore platform,ferris wheel, Palletizing robot,Rotary metallurgical furnace,can packing machine,Wind blade transporter,shield tunneling machine,tube push bench,excavator |

| Brand Name | SoCare-MSI |

| Place of Origin | China |

| Warranty | 18 months |

| Payment term | T/T is our first choice |

|

Packing details |

1,Filling with anti-rust oil 2.Corved with Plastic paper 3.Corved with kraft paper 4.Corved with Blue tie 5.Put in wooden box |

Slewing ring bearings are large-size rolling bearings that can accommodate axial, radial and moment loads acting either singly or in combination and in any direction .They can perform both slewing (oscillating) movements as well as rotational movements. A slewing ring bearing consist of an inner ring, an outer ring and rolling elements (balls or cylindrical rollers) that are separated by polyamide spacers .The rings, 1 of which usually incorporates a gear ,are provided with holes to accommodate attachment bolts. The holes may be threaded. Generally , only the raceways in the rings are hardened and precision-ground.Integral seals made of acrylonitrile-butadiene rubber (NBR) keep the lubricant in, and contaminants out of the bearing. Slewing ring bearings are re-lubricated through grease fittings to reduce maintenance and operating costs.

Compared to traditional pivot arrangements, slewing ring bearing arrangements provide many design and performance advantages. The compactness and large inner diameter simplify the design of the bearing arrangement and its associated components .The low sectional height of these bearings means that the pinion lever can be kept short. In most cases only flat mounting surfaces on the associated components are needed.

Slewing ring bearings were originally designed to be mounted only on horizontal support structure, but can now be used successfully in vertical bearing arrangements .

Slewing ring bearings perform extremely well in a variety of applications such as:

¤ Access platforms

¤ Bucket wheel excavators

¤ Conveyor booms

¤ Cranes of all type

¤ Small ,medium and large excavators

¤ InHangZhou tables

¤ Ladle turrets

¤ Offshore applications

¤ Robots

¤ Railway bogies

¤ Rotary platforms

¤ Stackers

¤ Solar mirrors

¤ Tunnel boring machines

¤ Wind turbines

Introduction

SCB-TR Tri-Roller Bearings

Increased stiffness and capacity over SCB-XR and SCB-DT

OD size range up : 48″- 275″

Construction

-Three separate rows of rollers

-Top and bottom rollers transmit thrust and moment load

-Middle roller transmits radial loading

-Sealed

-Ring Configuration:

Non geared

External gear

Internal gear

-Grease fittings for lubrication

Applications

-Mining

-Stackers and reclaimers

-Heavy equipment

-Cranes

-Radar

-Boring machines

Company Profile

Company Profile:

About SoCare :

The SoCare brand is synonymous with quality.

Now, we have become an even greater resource for our business partners. Due to embracing technical advances, product support, and service, we have become a truly solutions-oriented supplier.

SoCare is creating greater value for our partners.

These advances all work together to bring our customers the added benefit of higher productivity. In addition, we provide application specific products, leading edge design simulation tools, on sight engineering support, plant asset efficiency programs, and advanced supply chain management.

With SoCare you can expect more!

Application:

Slewing ring bearings can be widely used in lifting & transport machinery, mining machinery, construction machinery, port hoisting machinery, port oil transfer equipment, onshore and offshore crane, excavator, concrete machine, paper machine, plastic and rubber machine, weave machine, steel plant, electronic power plant, wind power generator, other construction and industry machines or equipments and other large rotary device.

Packaging & Shipping

Packing & Shipping:

Bearing surface is covered with the anti-rust oil first; and then wrapped with the plastic film;

And then packed with kraft paper and professional belts;

At last, with wooden box totally at the outer packing to invoid the rust or the moist;

We can depend on the customers demand to be packed.

After Sales Service

Our Service:

♥1.Your inquiry will be reply within 2 hours.

♥2.Fast delivery,within 15 working days.

♥3.Packing: you will receive a Perfect product with strong outside packing.

♥4.With advanced first-level facilities and testing equipment,to insure no mistake on the dimension of the bearings.

♥5.MOQ is 2 sets, Because we are manufacturer.

♥6.24 hours on line,no limited to talk to us.

♥7.Return Policy:We gladly accept returns for item purchased within a 15 day period, provided it is still in the original package, not used nor damaged.

♥8.Warranty Claims :The Warranty covers any Defect of the product for a period of 18 months. It does not cover items that are not correctly installed or over tightened which may cause premature failure. Installation or any other fee’s are not refundable.

FAQ

FAQ:

1.Q: Are you trading company or manufacturer ?

A: We are a manufacturing enterprise focusing on bearings and integrating research, production and sales with 20 years’ experience.

2.Q: How long is your delivery time?

A: Generally it is 7 days if the goods are in stock. or it is 15 days if the goods are not in stock, Also it is according to quantity.

3.Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance, balance before shipment.

4.What are the company’s delivery terms?

A:We can accept EXW,FOB,CFR,CIF,etc. You can choose the 1 which is the most convenient cost effective for you.

5.Q: Can you provide special customization according to the working conditions?

A: Sure, we can design and produce the slewing bearings for different working conditions.

6.How many the MOQ of your company?

A:Depending on the size of the bearing, the MOQ is variable, if you are interested, you can contact me for a quote.

7.Does the company accept OEM or customized bearings?

A:In addition to standard products, we also supply non-standard and modified standard products for special application. Meanwhile, we provide OEM service.

8.Can the company provide free samples?

A:We can provide samples for free. You only need to provide shipping.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | High Speed, Corrosion-Resistant, Heat-Resistant |

| Sealing Gland: | Sealed On Both Sides |

| Rolling-Element Number: | Single-Row |

| Roller Type: | Spherical Raceway |

| Material: | Alloy |

| Samples: |

US$ 0/Set

1 Set(Min.Order) | |

|---|

Signs of Wear or Damage in Linear Bearings and Maintenance

Identifying signs of wear or damage in linear bearings is essential for maintaining their performance and preventing costly failures. Here are common signs of wear and damage and how to address them:

- 1. Increased Friction:

If you notice increased resistance during linear motion, it could indicate that the bearing components are wearing out. This can lead to reduced efficiency and accuracy.

- Solution: Regular Lubrication:

Ensure proper lubrication of the bearings to minimize friction and prevent premature wear. Follow manufacturer recommendations for lubrication intervals and types.

- 2. Uneven Movement:

If the linear motion becomes uneven, jerky, or experiences sudden stops, it may be due to damaged bearing components.

- Solution: Inspection and Replacement:

Inspect the bearings and associated components for any signs of damage, such as dents or cracks. Replace any damaged parts to restore smooth motion.

- 3. Abnormal Noise:

Unusual noises during linear motion, such as grinding or clicking sounds, can indicate friction and wear within the bearings.

- Solution: Lubrication and Inspection:

Lubricate the bearings as recommended and inspect for any foreign particles or debris that might be causing the noise. Clean and replace components if necessary.

- 4. Increased Play or Clearance:

If there is noticeable play or excessive clearance in the linear system, it can affect precision and lead to inaccuracies.

- Solution: Adjustment or Replacement:

Check for loose bolts, misalignment, or worn components causing the play. Make necessary adjustments or replace worn parts to restore proper fit and function.

- 5. Reduced Performance:

If your linear system is no longer achieving the desired accuracy or performance, it could be due to worn bearings.

- Solution: Maintenance and Replacement:

Regularly perform maintenance tasks, such as cleaning, lubrication, and inspection. If performance does not improve, consider replacing the bearings with new ones.

- 6. Visible Damage:

Any visible signs of physical damage, such as deformation, corrosion, or cracks, require immediate attention.

- Solution: Replacement:

If the damage is severe, replace the damaged bearings promptly to avoid further issues.

Regular maintenance practices, including proper lubrication, cleaning, and inspection, are crucial for preventing wear and damage in linear bearings. Addressing any signs of wear early can extend the lifespan of the bearings and ensure consistent performance in various applications.

Advancements in Linear Bearing Technology

Recent years have witnessed significant advancements in linear bearing technology, leading to improved performance and expanded applications. Some notable advancements include:

- Rolling Element Innovations:

Manufacturers are introducing new types of rolling elements, such as ceramic balls and specialized coatings, to enhance load capacity, reduce friction, and extend the lifespan of linear bearings.

- Lubrication Solutions:

Advanced lubrication techniques, including self-lubricating materials and greases with extended lifetimes, are being developed to optimize the performance of linear bearings while reducing maintenance needs.

- Smart and Sensor-Integrated Bearings:

Linear bearings with built-in sensors provide real-time data on temperature, vibration, and wear. This enables predictive maintenance, early fault detection, and optimization of bearing performance.

- Improved Corrosion Resistance:

New materials and coatings are being employed to enhance the corrosion resistance of linear bearings. This is particularly beneficial in environments where exposure to moisture and corrosive substances is a concern.

- Reduced Friction and Energy Consumption:

Advanced engineering and design techniques are leading to lower friction coefficients and reduced energy consumption in linear bearings. This not only improves efficiency but also contributes to sustainability efforts.

- High-Speed Capabilities:

Linear bearings capable of operating at higher speeds are being developed to meet the demands of applications requiring rapid and precise movements, such as in the semiconductor and electronics industries.

- Enhanced Sealing and Contaminant Management:

New sealing technologies are being employed to provide better protection against contaminants and debris. This is critical for applications where cleanliness is paramount.

- Integration with Industry 4.0:

Linear bearings are increasingly designed to be compatible with Industry 4.0 principles, allowing them to be integrated into digital manufacturing and automation systems for improved overall efficiency.

- Material Advancements:

Novel materials with improved mechanical properties, wear resistance, and temperature tolerance are being used in the production of linear bearings, expanding their operating capabilities.

These recent advancements in linear bearing technology are enabling industries to achieve higher levels of precision, efficiency, reliability, and predictive maintenance, making linear bearings an essential component of modern machinery and systems.

Factors to Consider When Selecting a Linear Bearing

Choosing the right linear bearing for a specific application involves considering several critical factors to ensure optimal performance and longevity:

- Load Requirements:

Determine the magnitude and direction of the loads the linear bearing will experience. Consider both static and dynamic loads to select a bearing with an appropriate load capacity.

- Precision and Accuracy:

For applications requiring precise positioning, choose linear bearings with high precision and low backlash. Factors like repeatability and positional accuracy are crucial.

- Speed and Acceleration:

Consider the speed and acceleration at which the linear bearing will operate. Higher speeds may require bearings with lower friction and better heat dissipation.

- Environmental Conditions:

Assess the environmental factors such as temperature, humidity, and exposure to contaminants. Choose linear bearings with suitable materials and seals to withstand the conditions.

- Space Constraints:

Take into account the available space for mounting the linear bearing. Some applications may have limited space, necessitating compact and lightweight bearing options.

- Maintenance Requirements:

Consider the maintenance needs of the bearing. Bearings with self-lubricating properties or easy access for lubrication can reduce maintenance frequency.

- Mounting and Configuration:

Choose a linear bearing that can be easily mounted and integrated into your system’s design. Consider factors like mounting orientation and available mounting surfaces.

- Life Expectancy:

Estimate the expected lifespan of the linear bearing based on the application’s requirements. Select a bearing with a suitable design life to prevent premature failures.

- Cost and Budget:

Balance the desired performance with the available budget. Opt for linear bearings that provide the necessary features without exceeding cost limitations.

- Accessories and Add-ons:

Consider any additional accessories or add-ons, such as seals, lubrication systems, or end caps, that can enhance the bearing’s performance and protection.

- Manufacturer and Supplier:

Choose reputable manufacturers and suppliers that offer reliable products and good customer support. Quality assurance and technical assistance are essential.

Overall, a comprehensive assessment of these factors will help you select the most suitable linear bearing for your specific application, ensuring optimal performance, longevity, and cost-effectiveness.

editor by CX 2024-04-04

China wholesaler Lengthened Middle Self-Lubricating Linear Bearings Three Times Longer Linear Bearing Compact Linear Bearing Lmekc6luu connecting rod bearing

Product Description

Product Name: Asian Standard Linear Bearing

Linear motion bearings have the characteristics of smooth movement, low friction, high rigidity, long life, economy, easy to maintain or replace,

Our priority is 100% quality control and 100% customer satisfaction. We have a responsibility to help our customers to be competitive and advantageous in the market

Maneuvering linear slides such as machine slides, XY tables, roller tables and some dovetail sliders are moved by the bearings of the drive mechanism. Not all linear slides are electric, there are non-electric dovetail slides, ball bearing sliders and roller sliders that provide low friction linear motion for inertially or manually driven devices. All linear sliders provide linear motion according to bearings, whether they are ball bearings, dovetail bearings or linear roller bearings. XY tables, linear stages, machine sliders and other advanced sliders use linear motion bearings to provide multi-axis movement along X and Y.

Product General information

a, Low frictional linear motion

Steel balls are accurately guided by a retainer, so low frictional resistance and stable linear motion can be achieved.

Simple replacement of conventional plain bushings

It is easy to use Linear Bushings instead of conventional plain bushings, because both types are used with a round shaft, and no major redesign is necessary.

b, Wide variations

For each dimensional series, standard, adjustable clearance and open types are available with and without seals, so the best linear bushing for the application may be selected. In addition to the standard type, the high-rigidity long type is available. These types can be selected to suit the requirements in applications.

c, Miniature linear bushing LM Compact design

Miniature Linear Bushing is very small in size, allowing for compact assembly in machines and equipment.

d, High Reliability

ERSK linear bearing has very stringent quality control standards covering every production process. With proper lubrication and use,trouble-free operation for an extended period of time is possible.

e,Smooth Operation

The high efficiency of linear shaft is vastly superior to conventional shaft. The torque required is less than 30%. Linear motion can be easily changed from rotary motion. The linear bearings are moved very smoothly in the linear shaft.

f,High Durability

Rigidly selected materials, intensive heat treating and processing techniques, backed by years of experience,have resulted in the most durable linear bearings manufactured.

g,Easy interchangable

h,Easy maintenance