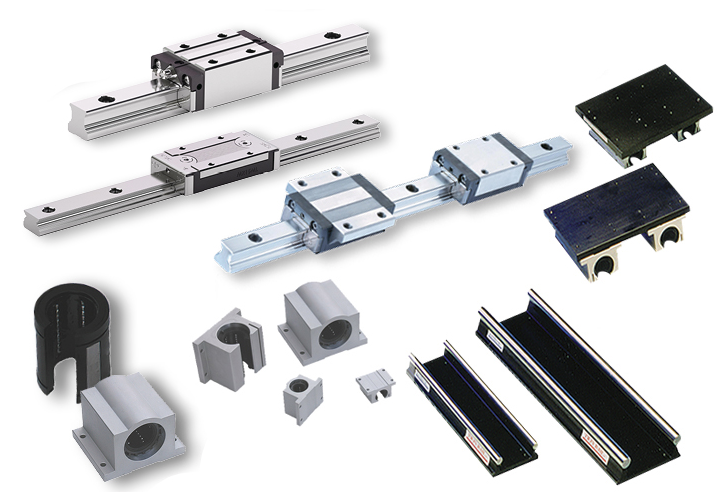

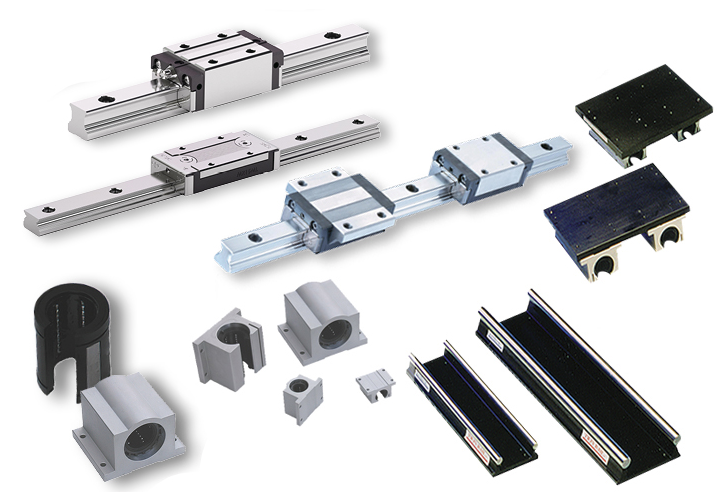

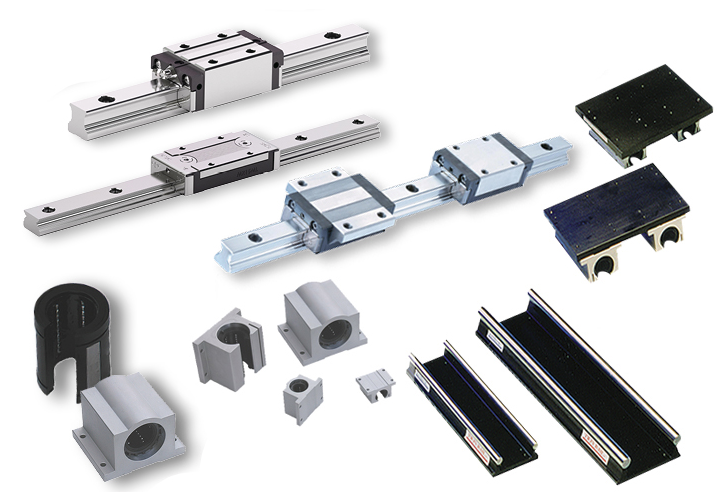

Product Description

Product Description

- Bearing structure: consists of outer cylinder, retainer, balls, side seals;

- Premium grade raw material: GCr15 bearing steel cylinder, G10 class precision ball, PA66 plastic retainer;

- Cylinder metal body is heat treated and hardened to enhance to the rigidity and working life;

- Both the inner bore and outer cylinder surface are ground several procedures to guarantee the precision;

- Completely washed by the super sonic washing machine, pre-lubricated;

- Main features: high precision and rigidity, low friction, ease of assembly and replacement, good interchangeability;

- Good quality at affordable rates, price is very economic and nice;

- Ideal transmission component for linear motion movement, widely used in CNC machines, factory automation, industrial machines, electric tools, textile machines, fitting equipment, etc.;

- Wide size range for option, models including(special size has to be customized):

LM3, LM4, LM5UU, LM6UU, LM8SUU, LM8UU, LM10UU, LM12UU, LM13UU, LM16UU, LM20UU, LM25UU, LM30UU, LM35UU, LM40UU, LM50UU, LM60UU, LM80UU, LM100UU, LM120UU, LM150UU, etc.

Product Parameters

Detailed Photos

Certifications

Packaging & Shipping

1.According to the quantity and the ship method of your order, we will choose the best packing ways.

2.For example, if the products shipped by TNT,DHL,FedEx, the goods would be packed by paper carton for economic delivery. As bulk order shipped by sea, the goods would be packed by wooden carton.

Our Advantages

FAQ

DO NOT worry about PRICE, we are manufacturer.

DO NOT worry about QUALITY, we have 16 years experience.

DO NOT worry about AFTER-SALES, we are 24 hours online.

Q1:Who we are?

We are the factory based in ZHangZhoug,China,start from 2007 sell to all over the.world.the factory area is around 45000 square meters.we have 900 employees.

Q2: Do you have a catalogue?

Can you send me the catalogue to have a check of all your products?

A: Yes , We have product catalogue.Please contact us on line or send an Email to sending the catalogue.

Q3: I can’t find the product on your catalogue, can you make this product for me?

A: Our catalogue shows most of our products,but not all.So just let us know what product do you need.

Q4 : Can you make customized products and customized packing?

A: Yes.We made a lot of customized products for our customer before.And we have many moulds for our customers already.About customized packing,we can put your Logo or other info on the packing.There is no problem.

Q5: Can you provide samples ? Are the samples free ?

A: Yes,we can provide samples.Normally,we provide 1-2pcs free samples for test or quality checking.But you have to pay for the

shipping cos.If you need many items, or need more qty for each item,we will charge for the samples.

Any requirements or question,Welcome to “Send” us an e-mail Now!

Recommend product

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Magnetically, Corrosion Resistant, High Speed, High Precision |

|---|---|

| Function: | Super |

| Flange Shape: | Oval |

| Shape: | Flange |

| Series: | LM |

| Material: | Bearing Steel |

| Samples: |

US$ 16.8/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Differences between Open-Type and Closed-Type Linear Bearings

Open-type and closed-type linear bearings are two common variations used in linear motion systems, each with its own advantages and considerations:

- 1. Open-Type Linear Bearings:

Open-type linear bearings, as the name suggests, have an open design that allows easy access to the bearing’s rolling elements and raceways. These bearings are characterized by:

- Quick Maintenance: Open-type bearings are easier to clean, lubricate, and inspect due to their open structure, making maintenance more convenient.

- Increased Contamination Risk: Because they are exposed, open-type bearings are more susceptible to dust, debris, and contamination, which can affect their performance and lifespan.

- 2. Closed-Type Linear Bearings:

Closed-type linear bearings are enclosed within a housing or carriage that provides protection from external elements. These bearings offer the following features:

- Enhanced Contamination Protection: Closed-type bearings are less vulnerable to contaminants and offer improved protection against dust, dirt, and debris, leading to longer service life.

- Reduced Accessibility: Maintenance and inspection of closed-type bearings might be more complex due to the need to disassemble the housing or carriage for access.

- Reduced Noise: The enclosed design of closed-type bearings can contribute to reduced noise levels, which is advantageous in noise-sensitive applications.

Choosing between open-type and closed-type linear bearings depends on the specific requirements of the application. If easy maintenance and accessibility are crucial, open-type bearings might be preferred. On the other hand, closed-type bearings offer better protection against contaminants and reduced noise, making them suitable for environments where cleanliness and quiet operation are essential.

Contribution of Linear Bearings to Smooth Movement of Conveyors and Linear Slides

Linear bearings play a crucial role in ensuring the smooth movement of industrial conveyors and linear slides by providing low-friction support and guiding mechanisms. Here’s how linear bearings contribute to their operation:

- Smooth Motion: Linear bearings offer precise and smooth linear motion to conveyors and linear slides, allowing materials or objects to move seamlessly along a defined path.

- Low Friction: The design of linear bearings minimizes friction between the moving parts, reducing energy consumption and wear. This is particularly important for conveyors and slides that require frequent and continuous movement.

- Guidance: Linear bearings guide the movement of the conveyor belts or linear slides, ensuring that they stay on track and follow the desired path without deviation.

- Load Support: Linear bearings provide support for both radial and axial loads, allowing conveyors to carry heavy loads and linear slides to accommodate objects or components without sacrificing smoothness.

- Precision: Linear bearings offer high precision and accuracy, which is essential for applications where precise positioning is required, such as in automated manufacturing processes.

- Reduced Noise and Vibration: Linear bearings contribute to quieter operation by reducing noise and absorbing vibrations generated during movement. This is beneficial in environments where noise reduction is important.

- Longevity: By minimizing friction and wear, linear bearings enhance the longevity of conveyors and linear slides, reducing the need for frequent maintenance and replacement.

In industrial settings, linear bearings ensure that conveyors efficiently transport materials, products, or components, while linear slides provide controlled and accurate movement for various applications. Whether in manufacturing, logistics, or automation, the use of linear bearings results in enhanced efficiency, reduced downtime, and improved overall performance.

Design Principles and Functionalities of Linear Bearings

Linear bearings are designed with specific principles to facilitate controlled linear motion along a single axis. These design principles contribute to their functionalities, making them essential components in various applications:

- Rolling Elements:

Linear bearings typically feature rolling elements, such as balls or rollers, that move along a track or rail. These rolling elements reduce friction and enable smooth linear motion.

- Guiding Mechanism:

Linear bearings incorporate a guiding mechanism to constrain the motion to a single axis. This guiding mechanism ensures that the linear bearing moves precisely along the desired path.

- Load Distribution:

The design of linear bearings allows for effective distribution of loads, both in the radial and axial directions. This load distribution ensures stability and prevents excessive stress on individual components.

- Rail or Track:

Linear bearings typically run along a rail or track that provides a smooth and accurate path for the rolling elements. The rail is designed to resist wear and maintain its precision over time.

- Cage or Carriage:

Linear bearings use a cage or carriage to house the rolling elements and maintain their proper spacing. This arrangement ensures even load distribution and smooth movement.

- Sealing and Lubrication:

Linear bearings often incorporate sealing mechanisms to protect the rolling elements from contaminants and to retain lubrication. Proper lubrication ensures smooth motion and extends the bearing’s lifespan.

- Mounting Options:

Linear bearings are designed to be mounted in various ways, depending on the application’s requirements. Mounting options include flange-mounted, base-mounted, or end-supported configurations.

- Adjustability:

Many linear bearings are designed with provisions for adjustment, allowing users to fine-tune the preload or clearance to optimize performance and minimize play.

- Materials:

Linear bearings are constructed from materials that offer high wear resistance, durability, and corrosion resistance. Common materials include steel, stainless steel, and various engineering plastics.

- Accessories:

Accessories such as end caps, seals, and lubrication systems can enhance the functionality and lifespan of linear bearings by providing protection and ensuring proper maintenance.

Functionalities of linear bearings include providing precise linear motion, guiding components along a defined path, minimizing friction, distributing loads, and maintaining stability. The design principles ensure reliable operation and make linear bearings indispensable in applications requiring controlled and accurate linear motion.

editor by CX 2024-05-14

China high quality Original Brand PMI Msa45e Linear Guideway and Block Bearing Msa25essfcnx for CNC Machine deep groove ball bearing

Product Description

Original Brand PMI Msa45e Linear Xihu (West Lake) Dis.way and Block Bearing MSA25ESSFCNX for CNC machine3d printer

PMI linear bearing features

1. High positioning accuracy, high repeatability

2. Low frictional resistance, high precision maintained for long period

3. High rigidity with four-way load design

4. Suitable for high speed operation

5. Easy installation with interchangeability

Specifications

PMI linear bearing:

1.Origin:PMI ZheJiang

2.Linear CZPT series:MSA,MSB

3.High precision

4.High rigidity

Packaging & Delivery

Packaging Detail:1.individual poly bag +box packing 2.poly bag + individual box +carton+ woven bag 3.poly bag + box +wooden case 4.plastic package +wooden case 5.as your requirement

Delivery Detail:PMI linear bearing will be send within 3 days after payment

| External dimension | Carriage dimension | Rail dimension | Weight | |||||||||

| Height | Width | Length | Width | Height | Pitch | Carriage | Rail | |||||

| ModelNo. | H | W | L | W2 | H2 | B | C | W1 | H1 | P | kg | kg/m |

| MSA15S | 28 | 34 | 56.3 | 9.5 | 4.2 | 26 | 26 | 15 | 15 | 60 | 0.18 | 1.5 |

| MSA20S | 30 | 44 | 72.9 | 12 | 5 | 32 | 36 | 20 | 18 | 60 | 0.3 | 2.4 |

| MSA20LS | 88.8 | 50 | 0.39 | |||||||||

| MSA25S | 40 | 48 | 81.6 | 12.5 | 6.5 | 35 | 35 | 23 | 22 | 60 | 0.52 | 3.4 |

| MSA25LS | 100.6 | 50 | 0.58 | |||||||||

| MSA30S | 45 | 60 | 97 | 16 | 8 | 40 | 40 | 28 | 26 | 80 | 0.86 | 4.8 |

| MSA30LS | 119.2 | 60 | 1.12 | |||||||||

| MSA35S | 55 | 70 | 111.2 | 18 | 9.5 | 50 | 50 | 34 | 29 | 80 | 1.45 | 6.6 |

| MSA35LS | 136.6 | 72 | 1.9 | |||||||||

| MSA45S | 70 | 86 | 137.7 | 20.5 | 10 | 60 | 60 | 45 | 38 | 105 | 2.83 | 11.5 |

| MSA45LS | 169.5 | 80 | 3.7 | |||||||||

| MSA55S | 80 | 100 | 161.5 | 23.5 | 13 | 75 | 75 | 53 | 44 | 120 | 4.12 | 15.5 |

| MSA55LS | 199.5 | 95 | 4.91 | |||||||||

| MSA65S | 90 | 126 | 199 | 31.5 | 15 | 76 | 70 | 63 | 53 | 150 | 6.43 | 21.9 |

| MSA65LS | 253 | 120 | 8.76 | |||||||||

PMI slide rail series

1.MSA series : MSA-A/MSA-LA,MSA-E/MSA-LE,MSA-S/MSA-LS

| MSA 15A | MSA 20A | MSA 20LA | MSA 25A | MSA 25LA | MSA 30A | MSA 30LA | MSA 35A | MSA 35LA | MSA 45A |

| MSA 45LA | MSA 15E | MSA 20E | MSA 20LE | MSA 25E | MSA 25LE | MSA 30E | MSA 30LE | MSA 35E | MSA 35LE |

| MSA 45E | MSA 45LE | MSA 55E | MSA 55LE | MSA 65E | MSA 65LE | MSA 15S | MSA 20S | MSA 20LS | MSA 25S |

| MSA 25LS | MSA 30S | MSA 30LS | MSA 35S | MSA 35LS | MSA 45S | MSA 45LS | MSA 55S | MSA 55LS | MSA 65S |

2.MSB series: MSB-TE/MSB-E,MSB-TS/MSB-S

| MSB 15TE | MSB 15E | MSB 20TE | MSB 20E | MSB 25TE | MSB 25E | MSB 30TE | MSB 30E | MSB 15TS | MSB 15S |

| MSB 20TS | MSB 20S | MSB 25TS | MSB 25S | MSB 30TS | MSB 30S | MSB 35S | MSB 35LS |

3.MSR series: MSR-E/MSR-LE,MSR-S/MSR-LS

| MSR 25E | MSR 25LE | MSR 30E | MSR 30LE | MSR 35E | MSR 35LE | MSR 45E | MSR 45LE | MSR 55E | MSR 55LE | MSR 65LE |

| MSR 25S | MSR 25LS | MSR 30S | MSR 30LS | MSR 35S | MSR 35LS | MSR 45S | MSR 45LS | MSR 55S | MSR 55LS | MSR 65LS |

4.MSC series: MSC-M/MSC-LM

| MSC 7M | MSC 7LM | MSC 9M | MSC 9LM | MSC 12M | MSC 12LM | MSC 15M | MSC 15LM |

5.SME series: SME-EA/SME-LEA,SME-EB/SME-LEB,SME-SA/SME-LSA,SME-SB/LSB SME-SV/LSV

| SME 15EA | SME 15LEA | SME 20EA | SME 20LEA | SME 25EA | SME 25LEA | SME 30EA | SME 30LEA | SME 35EA | SME 35LEA |

| SME 45EA | SME 45LEA | SME 15EB | SME 15LEB | SME 20EB | SME 20LEB | SME 25EB | SME 25LEB | SME 15SA | SME 15LSA |

| SME 20SA | SME 20LSA | SME 25SA | SME 25LSA | SME 30SA | SME 30LSA | SME 35SA | SME 35LSA | SME 45SA | SME 45LSA |

| SME 15SB | SME 15LSB | SME 20SB | SME 20LSB | SME 25SB | SME 25LSB | SME 25SV | SME 25LSV | SME 30SB | SME 30LSB |

| SME 35SB | SME 35LSB | SME 45SB | SME 45LSB | SME 15SB | SME 15LSB | SME 20SB | SME 20LSB | SME 25SB | SME 25LSB |

| SME 25SV | SME 25LSV | SME 30SB | SME 30LSB | SME 35SB | SME 35LSB | SME 45SB | SME 45LSB |

6.SMR series: SMR-E/SME-LE,SMR-S/SME-LS

| SMR 25E | SMR 25LE | SMR 30E | SMR 30LE | SMR 35E | SMR 35LE | SMR 45E | SMR 45LE | SMR 55E | SMR 55LE | SMR 65LS |

| SMR 65LE | SMR 25S | SMR 25LS | SMR 30S | SMR 30LS | SMR 35S | SMR 35LS | SMR 45S | SMR 45LS | SMR 55S | SMR 55LS |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Express: | TNT, DHL, FedEx, EMS |

|---|---|

| Accurancy Grade: | N; H; P; Sp; up |

| Sample: | Avaliable |

| Brand Name: | PMI |

| Transport Package: | as Per Client′s Requirement |

| Trademark: | PMI |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Considerations for Selecting the Right Type and Size of Linear Bearing

Choosing the appropriate type and size of linear bearing requires careful consideration of various factors to ensure optimal performance and compatibility with the application. Here are important considerations to keep in mind:

- 1. Load Capacity:

Determine the maximum load the linear bearing will need to support. Consider both static and dynamic loads to select a bearing that can handle the expected weight and forces.

- 2. Speed and Acceleration:

Assess the required speed and acceleration of the linear motion. Different linear bearing types have different speed limitations, so choose one that can accommodate the desired motion profile.

- 3. Precision and Accuracy:

If your application requires precise positioning, choose linear bearings that offer high accuracy and repeatability. Linear ball bearings are known for their precision, while linear roller bearings offer higher load capacity.

- 4. Environment:

Consider the operating environment, including temperature, humidity, dust, and potential exposure to chemicals. Select linear bearings that are designed to withstand the specific environmental conditions.

- 5. Rail or Shaft Compatibility:

Ensure that the chosen linear bearing is compatible with the rail or shaft you intend to use. Proper fit and alignment are crucial for smooth motion and long bearing life.

- 6. Space Constraints:

If your application has limited space, choose compact linear bearings that can fit within the available area without compromising performance.

- 7. Maintenance Requirements:

Consider the level of maintenance your application can accommodate. Some linear bearings are self-lubricating, reducing the need for frequent maintenance.

- 8. Noise Level:

For noise-sensitive environments, opt for linear bearings that provide quiet operation to avoid disruptions caused by excessive noise.

- 9. Mounting Options:

Consider how the linear bearing will be mounted and integrated into your system. Different bearings may require specific mounting configurations.

- 10. Cost and Budget:

Balance the desired features and performance with your budget constraints. While high-performance linear bearings may offer advanced features, they can also come at a higher cost.

By carefully evaluating these factors, you can choose the most suitable type and size of linear bearing for your specific application. Consulting with bearing manufacturers and engineers can also provide valuable insights to ensure the optimal selection.

Contribution of Linear Bearings to Smooth Movement of Conveyors and Linear Slides

Linear bearings play a crucial role in ensuring the smooth movement of industrial conveyors and linear slides by providing low-friction support and guiding mechanisms. Here’s how linear bearings contribute to their operation:

- Smooth Motion: Linear bearings offer precise and smooth linear motion to conveyors and linear slides, allowing materials or objects to move seamlessly along a defined path.

- Low Friction: The design of linear bearings minimizes friction between the moving parts, reducing energy consumption and wear. This is particularly important for conveyors and slides that require frequent and continuous movement.

- Guidance: Linear bearings guide the movement of the conveyor belts or linear slides, ensuring that they stay on track and follow the desired path without deviation.

- Load Support: Linear bearings provide support for both radial and axial loads, allowing conveyors to carry heavy loads and linear slides to accommodate objects or components without sacrificing smoothness.

- Precision: Linear bearings offer high precision and accuracy, which is essential for applications where precise positioning is required, such as in automated manufacturing processes.

- Reduced Noise and Vibration: Linear bearings contribute to quieter operation by reducing noise and absorbing vibrations generated during movement. This is beneficial in environments where noise reduction is important.

- Longevity: By minimizing friction and wear, linear bearings enhance the longevity of conveyors and linear slides, reducing the need for frequent maintenance and replacement.

In industrial settings, linear bearings ensure that conveyors efficiently transport materials, products, or components, while linear slides provide controlled and accurate movement for various applications. Whether in manufacturing, logistics, or automation, the use of linear bearings results in enhanced efficiency, reduced downtime, and improved overall performance.

Advantages of Linear Bearings over Other Bearing Types

Linear bearings offer several distinct advantages when compared to other types of bearings, particularly in applications that require controlled linear motion. These benefits contribute to their widespread use across various industries:

- Precise Linear Motion:

Linear bearings are designed specifically for linear motion, providing accurate and controlled movement along a defined path. This precision is essential in applications that demand accurate positioning and repeatability.

- Low Friction:

Linear bearings are designed to minimize friction during motion. The reduced friction translates to smoother movement, reduced wear, and improved efficiency, making them suitable for applications requiring consistent motion.

- High Load Capacity:

Linear bearings can handle significant loads in both radial and axial directions. This capability allows them to support heavy components and maintain stability under various loads.

- Minimal Maintenance:

Due to their design and minimal contact between moving parts, linear bearings require less maintenance compared to other types of bearings. This is particularly advantageous in hard-to-reach or inaccessible areas.

- Guided Motion:

Linear bearings provide guided and constrained motion along a single axis. This guidance eliminates the need for complex guiding mechanisms, reducing design complexity and simplifying assembly.

- Compact Design:

Linear bearings have a compact form factor, making them suitable for applications with limited space. Their small footprint allows for efficient use of available area.

- Low Noise and Vibration:

Linear bearings generate minimal noise and vibration during operation, contributing to quieter and more comfortable working environments in applications such as medical devices and precision machinery.

- Smooth Movement:

Linear bearings offer smooth and consistent movement, essential for applications requiring continuous and controlled motion, such as robotic systems and conveyor belts.

- Customization:

Linear bearings can be designed to fit specific application requirements, including load capacity, travel distance, and environmental conditions. This customization enhances their suitability for diverse applications.

- Reduced Wear:

The low friction and guided motion of linear bearings result in reduced wear on both the bearing and the mating surface, leading to longer service life and reduced maintenance costs.

Overall, the benefits of using linear bearings make them a preferred choice in applications that demand accurate linear motion, efficient load handling, and reduced maintenance. Their ability to deliver precision, stability, and reliability contributes to improved performance across various industries.

editor by CX 2024-04-25

China Custom Deep Groove Ball Tapered Roller Angular Contact Linear Bearing Bearing All Kinds of Bearing with So Many Brand wheel bearing

Product Description

Product Parameters

|

Product Name |

Angular Contact Ball Bearing 7009 |

|

Material |

Chrome Steel |

|

Place of Origin |

China |

|

Feature |

Low noise,low libration,long life |

|

Number of Row |

Single Row |

|

Inside diameter |

45mm |

|

Outside Diameter |

75mm |

|

Packing |

According to the buyer requests for packaging |

Product Description

Detailed Photos

Application of Bearing

Strict Testing Produre

Company Profile

Packaging & Shipping

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.We have our own brand:HQA .If you interested in our product,I can take you to visit our factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in ZheJiang Province,You can take the high-speed rail or plane to visit.

Q: Do you provide samples ? it is free charge?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q:The MOQ is how much?

A: About ordinary standard type of bearing ,We have rich inventory,not have MOQ,if your need a

product is Non-standard size,need customize,we will according the product size to determine the MOQ.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Non-Aligning Bearing |

|---|---|

| Separated: | Separated |

| Feature: | Low Temperature, Corrosion Resistant, High Temperature, Low Viberation |

| Rows Number: | Single |

| Raceway: | Spherical Raceway |

| Material: | Bearing Steel |

| Samples: |

US$ 0.01/Set

1 Set(Min.Order) | |

|---|

Challenges and Solutions for Addressing Friction and Wear in Linear Bearings

Friction and wear are common challenges in linear bearings that can impact their performance and lifespan. Here are the challenges and some solutions to address them:

- 1. Challenge: Friction:

Friction between the bearing components can lead to increased energy consumption, heat generation, and reduced efficiency.

- Solution: Lubrication:

Proper lubrication is essential to minimize friction. Lubricants reduce the contact between moving parts, allowing smoother motion and reducing wear. Choosing the right lubricant and applying it correctly can significantly mitigate friction-related issues.

- 2. Challenge: Wear:

Continuous movement can lead to wear on the bearing surfaces, affecting precision and performance over time.

- Solution: Regular Maintenance:

Implementing a regular maintenance schedule can help monitor wear and replace worn components before they compromise performance. This includes cleaning, re-lubrication, and periodic inspection of the bearing’s condition.

- 3. Challenge: Contaminants:

Dust, debris, and foreign particles can enter the bearing system, leading to increased friction and accelerated wear.

- Solution: Sealing and Protection:

Using seals, covers, or protective enclosures can help prevent contaminants from entering the bearing system. These protective measures maintain the integrity of the lubricant and extend the bearing’s lifespan.

- 4. Challenge: Improper Installation:

If linear bearings are not installed correctly, misalignment and uneven load distribution can contribute to friction and wear.

- Solution: Precise Installation:

Follow manufacturer guidelines for proper installation, ensuring accurate alignment and even load distribution. This reduces the risk of premature wear and ensures optimal performance.

- 5. Challenge: Inadequate Lubrication:

If the linear bearings are under-lubricated or over-lubricated, it can lead to increased friction and wear.

- Solution: Lubrication Management:

Monitor and manage lubrication levels to ensure they are within the recommended range. Regularly assess the lubricant’s condition and replenish as needed to maintain optimal performance.

- 6. Challenge: High Loads and Speeds:

High loads and speeds can increase friction and wear on linear bearings.

- Solution: Proper Selection:

Select linear bearings that are designed to handle the specific loads and speeds of the application. This ensures that the bearings can operate effectively under the given conditions.

Addressing friction and wear challenges in linear bearings requires a combination of proper maintenance practices, appropriate lubrication, protective measures, and careful selection of bearings. By implementing these solutions, the performance and longevity of linear bearings can be optimized.

Contribution of Linear Bearings to Smooth Movement of Conveyors and Linear Slides

Linear bearings play a crucial role in ensuring the smooth movement of industrial conveyors and linear slides by providing low-friction support and guiding mechanisms. Here’s how linear bearings contribute to their operation:

- Smooth Motion: Linear bearings offer precise and smooth linear motion to conveyors and linear slides, allowing materials or objects to move seamlessly along a defined path.

- Low Friction: The design of linear bearings minimizes friction between the moving parts, reducing energy consumption and wear. This is particularly important for conveyors and slides that require frequent and continuous movement.

- Guidance: Linear bearings guide the movement of the conveyor belts or linear slides, ensuring that they stay on track and follow the desired path without deviation.

- Load Support: Linear bearings provide support for both radial and axial loads, allowing conveyors to carry heavy loads and linear slides to accommodate objects or components without sacrificing smoothness.

- Precision: Linear bearings offer high precision and accuracy, which is essential for applications where precise positioning is required, such as in automated manufacturing processes.

- Reduced Noise and Vibration: Linear bearings contribute to quieter operation by reducing noise and absorbing vibrations generated during movement. This is beneficial in environments where noise reduction is important.

- Longevity: By minimizing friction and wear, linear bearings enhance the longevity of conveyors and linear slides, reducing the need for frequent maintenance and replacement.

In industrial settings, linear bearings ensure that conveyors efficiently transport materials, products, or components, while linear slides provide controlled and accurate movement for various applications. Whether in manufacturing, logistics, or automation, the use of linear bearings results in enhanced efficiency, reduced downtime, and improved overall performance.

Advantages of Linear Bearings over Other Bearing Types

Linear bearings offer several distinct advantages when compared to other types of bearings, particularly in applications that require controlled linear motion. These benefits contribute to their widespread use across various industries:

- Precise Linear Motion:

Linear bearings are designed specifically for linear motion, providing accurate and controlled movement along a defined path. This precision is essential in applications that demand accurate positioning and repeatability.

- Low Friction:

Linear bearings are designed to minimize friction during motion. The reduced friction translates to smoother movement, reduced wear, and improved efficiency, making them suitable for applications requiring consistent motion.

- High Load Capacity:

Linear bearings can handle significant loads in both radial and axial directions. This capability allows them to support heavy components and maintain stability under various loads.

- Minimal Maintenance:

Due to their design and minimal contact between moving parts, linear bearings require less maintenance compared to other types of bearings. This is particularly advantageous in hard-to-reach or inaccessible areas.

- Guided Motion:

Linear bearings provide guided and constrained motion along a single axis. This guidance eliminates the need for complex guiding mechanisms, reducing design complexity and simplifying assembly.

- Compact Design:

Linear bearings have a compact form factor, making them suitable for applications with limited space. Their small footprint allows for efficient use of available area.

- Low Noise and Vibration:

Linear bearings generate minimal noise and vibration during operation, contributing to quieter and more comfortable working environments in applications such as medical devices and precision machinery.

- Smooth Movement:

Linear bearings offer smooth and consistent movement, essential for applications requiring continuous and controlled motion, such as robotic systems and conveyor belts.

- Customization:

Linear bearings can be designed to fit specific application requirements, including load capacity, travel distance, and environmental conditions. This customization enhances their suitability for diverse applications.

- Reduced Wear:

The low friction and guided motion of linear bearings result in reduced wear on both the bearing and the mating surface, leading to longer service life and reduced maintenance costs.

Overall, the benefits of using linear bearings make them a preferred choice in applications that demand accurate linear motion, efficient load handling, and reduced maintenance. Their ability to deliver precision, stability, and reliability contributes to improved performance across various industries.

editor by CX 2024-04-17

China wholesaler Wj506 Distributor Original CZPT CZPT CZPT CZPT CZPT CZPT Ball Bearing 6000 6002 6004 6006 6008 6200 Tapper Roller Bearing Linear Bearing Deep Groove Ball Bearing with Great quality

Product Description

Product Description

WHY CHOOSE E-ASIA BEARING?

1) 20 years of rich bearing industry export experience

2) ISO & MPA & CE & SGS & BV certified

3) Professional engineers team and Superior machines

4) 1 hour to HangZhou port or ZheJiang port

5) Strict quality inspection (3 steps) before shipment, such as SGS/BV third party certified.

CHOOSE E-ASIA REFUSED ONE TIME BUSINESS

| Deep groove ball bearing | 5 88506 88507 88508A 88508 88509 622 62303 62304 62305 62306 62307 62308 62309 62310 |

| Taper roller bearings | 35712 35713 35714 35715 35716 35717 35718 35719 35710 35711 35712 35713 35714 35715 35716 35717 35718 35719 35710 35711 35712 35714 35716 35718 35710 35712 35714 35716 35710 35714 30302 30303 30304 30305 30306 30307 30308 3 3 0571 3 0571 3 0 30321 30322 30324 30326 30328 30330 30332 30334 32204 32205 32206 32207 32208 32209 32210 32211 32212 32213 32214 32215 32216 32217 32218 32219 32220 32221 32222 32224 32226 32228 32230 32232 32236 32238 32240 32244 32248 32303 32304 32305 32306 32307 32308 32309 32310 32311 32312 32313 32314 32315 32316 32317 32318 32319 32320 32321 32322 32324 32326 32330 32334 31303 31304 31305 31306 31307 31308 31309 31310 31311 31312 31313 31314 31315 31316 31317 31318 31319 31320 31324 31326 31328 31332 32 325714 320726 325718 53856k 53860 |

| Self-aligning ball bearings | |

| spherical plain bearing | GE4E GE5E GE6E GE8E GE10E GE12E GE15ES GE17ES GE20ES GE25ES GE30ES GE35ES GE40ES GE45ES GE50ES GE60ES GE70ES GE80ES GE90ES GE1 110145 120155 130170 140180 150190 165710 |

| Thrust ball bearing | 511 234415 234416 234417 234418 234419 234420 234421 234422 234424 234426 234428 234430 234432 234438 234440 234714 234715 234716 234717 234718 234719 234720 234721 234722 234722 347262 347282 347302 347322 347382 34740 |

| Cylindrical Roller Bearings | NU313EMA NU2313EMA NU2314EMA NU415EMA NU216EMA NU2216EMA NJ2216EMA NUP2216EMA NU316EMA NU2316EMA NU217EMA NU2217EMA NU317EMA NU2317EMA NJ2317EMA NU218EMA NJ218EMA NU2218EMA NJ2218EMA NUP2218EMA NU318EMA NJ318EMA NU2318EMA NJ2318EMA NU219EMA NJ219EMA NU2219EMA NJ2219EMA NU319EMA NJ319EMA NU2319EMA NJ2319EMA NU220EMA NJ220EMA NU2220EMA NJ2220EMA NU320EMA NJ320EMA NU2320EMA NJ2320EMA NU222EMA NJ222EMA NU2222EMA NJ2222EMA NU322EMA NJ322EMA NU2322EMA NJ2322EMA NU1571MA NU224EMA NJ224EMA NU2224EMA NJ2224EMA NU324EMA NJ324EMA NU2324EMA NJ2324EMA NU1026MA NU226EMA NJ226EMA NU2226EMA NJ2226EMA NU326EMA NJ326EMA NU2326EMA NJ2326EMA NU1571MA NU228EMA NJ228EMA NU2228EMA NJ2228EMA NU328EMA NJ328EMA NU2328EMA NJ2328EMA NU1030MA NU230EMA NJ230EMA NUP230EMA NU2230EMA NJ2230EMA N2230EMB NU330EMA NJ330EMA NU2330EMA NJ2330EMA NU1032MA NU232EMA NJ232EMA NUP232EMA NU2232EMA NJ2232EMA NU332EMA NJ332EMA NU2332EMA NJ2332EMA NU1034MA NU3034EMA NU234EMA NJ234EMA NU2234EMA NJ2234EMA NU334EMA NJ334EMA NU2334EMA NJ2334EMA NU1036MA NU236EMA NJ236EMA NU2236EMA NJ2236EMA NU336EMA NJ336EMA NU2336EM NJ2336EMA NU1038MA NU238EMA NJ238EMA NU2238EMA NJ2238EMA NU338EMA NJ338EMA NU2338EMA NJ2338EMA NU1040MA NU240EMA NJ240EMA NU2240EMA NJ2240EMA NU340EMA NJ340EMA NU2340EMA NJ2340EMA NU1044MA NJ1044MA NU3044EMA NU244EMA NJ244EMA NU2244EMA NJ2244EMA NU344EMA NJ344EMA NU2344EMA NJ2344EMA N2344EMB NU1048MA NU248EMA NJ248EMA NU348EMA NJ348EMA NU2348EMA NJ2348EMA NU1052MA NU3052MA NU252MA NUP252MA NU2252MA NU2352EMA NU1056MA NU1060MA NU1964MA NF2964EMB NU1064MA NU2264MA NF2968EMB NU1068MA NU3068EMA NU3168EMA NU2372EMA NU1072MA NU1076MA NJ2980EMA NU1080MA NU2080EMA NF2984EMB NU1088MA NU2088EMA NU3188EMA NJ2892EMA NF2992EMB NU3192EMA NU1096EMA NJ1096EMA NU31/500EMA NU18/560MA NU30/600EMA NU20/630EMA NU20/670EMA NU20/670EMA NU30/670EMA NJ28/710EMA NJ29/710MA NU20/750EMA NU20/800EMA NU20/850EMA NU39/900EMA NU20/900EMA NJ18/1120EMA105RU32 105RN32 105RJ32 105RF32 105RT32 170RU51 170RN51 170RJ51 170RF51 170RT51 170RU91 170RN91 170RJ91 170RF91 170RT91 170RU93 170RN93 170RJ93 170RF93 170RT93 180RU51 180RN51 180RJ51 180RF51 180RT51 180RU91 180RN91 180RJ91 180RF91 180RT91 190RU91 190RN91 190RJ91 190RF91 190RT91 190RU92 190RN92 190RJ92 190RF92 190RT92 200RU91 200RN91 200RJ91 200RF91 200RT91 200RU92 200RN92 200RJ92 200RF92 200RT92 210RU92 210RN92 210RJ92 210RF92 210RT92 220RU51 220RN51 220RJ51 220RF51 220RT51 220RU91 220RN91 220RJ91 220RF91 220RT91 220RU92 220RN92 220RJ92 220RF92 220RT92 240RU91 240RN91 240RJ91 240RF91 240RT91 250RU91 250RN91 250RJ91 250RF91 250RT91NCF2922V NCF2924V NCF2926V NCF2928V NCF2930V NCF2932V NCF2934V NCF2936V NCF2938V NCF1840V NCF2940V NCF1844V NCF2944V NCF1852V NCF2952V NCF2960V NCF1864V NCF2964V NCF1868V NCF1876V NCF2976V NCF1880V NCF1884V NCF1888V NCF1892V NCF2992V NCF2996V NCF18/500V NCF29/500V NCF18/530V NCF18/560V NCF18/600V NCF18/630V NCF18/670V NCF18/710V NCF18/750V NCF18/800VNNU4930MAW33 NNU4932MAW33 NNU4934MAW33 NNU4936MAW33 NNU4938MAW33 NNU4940MAW33 NNU4140MAW33 NNU4944MAW33 NNU4144MAW33 NNU4948MAW33 NNU4148MAW33 NNU4952MAW33 NNU4152MAW33 NNU4956MAW33 NNU4156MAW33 NNU4960MAW33 NNU4160MAW33 NNU4964MAW33 NNU4164MAW33 NNU4968MAW33 NNU4068MAW33 NNU4168MAW33 NNU4972MAW33 NNU4072MAW33 NNU4172MAW33 NNU4976MAW33 NNU4076MAW33 NNU4176MAW33 NNU4980MAW33 NNU4080MAW33 NNU4180MAW33 NNU4984MAW33 NNU4084MAW33 NNU4184MAW33 NNU4988MAW33 NNU4088MAW33 NNU4188MAW33 NNU4992MAW33 NNU4092MAW33 NNU4192MAW33 NNU4996MAW33 NNU4096MAW33 NNU4196MAW33 NNU49/500MAW33 NNU40/500MAW33 NNU49/530MAW33 NNU40/530MAW33 NNU49/560MAW33 NNU49/600MAW33 NNU49/630MAW33 NNU49/670MAW33 NNU40/670MAW33 NNU49/710MAW33 NNU49/750MAW33 NNU49/800MAW33 NNU49/850MAW33 NNU49/900MAW33 |

Company Profile

E-Asia was set up in 1996 and located at HangZhou, a beautiful city in China. Our company is bearing manufacturer and NSK CZPT CZPT CZPT CZPT HRB LYC NACHI C&U bearing distributor. We also provide OEM beaings.Since it was first established, E-AISA was dedicated in research, development and manufacture of bearings. Now, E-AISA has become main and 1 of the first grade suppliers of all kinds of bearings.

Our products include: Deep Groove Ball Bearings, Self-aligning Ball Bearings, Spherical Bearings, Tapered Roller Bearings,Cylindrical Roller Bearings, Needle Roller Bearings, Self-aligning Roller Bearings, Angular Contact Ball Bearings, Thrust Ball Bearings and Trust Roller Bearings and Special Bearings.

E-Asia is a backbone enterprise for bearing production in China. With an area of 60, 000 square meters, more than 260 sets devices and machines, and around 200 employees, our company annually turns out more than 6 million sets bearings.

Our Bearings are exported to the USA, Canada, UK, Germany, Poland, Italy, Russia, the Middle East, Africa and other countries and regions of the world. E-Asia Bearing Co. Ltd. Is committed to the introduction of high-quality bearing products. Our company have more than 200 employees.

Our brands include ZWZ bearings, CZPT bearings, CZPT bearings, CZPT bearings, CZPT bearings, CZPT bearings and so forth.

Our belief is “Specialization is quality; Quality is the future. Any product with 0.01% defect is 100% reject” is our quality policy.

Packaging & Shipping

FAQ

1.What is the minimum order quantity for this product?

Can be negotiated, we will try our best to meet customer needs.Our company is mainly based on wholesale sales, most customers’orders are more than 1 ton.

2.What is your latest delivery time?

Most orders will be shipped within 3-5 days of payment being received.

3.Does your company have quality assurance?

Yes, for 2 years.

4.What is the competitiveness of your company’s products compared to other companies?

High precision, high speed, low noise.

5.What are the advantages of your company’s services compared to other companies?

Answer questions online 24 hours a day, reply in a timely manner, and provide various documents required by customers for customs clearance or sales. 100% after-sales service.

6.Which payment method does your company support?

Do our best to meet customer needs, negotiable.

7.How to contact us quickly?

Please send us an inquiry or message and leave your other contact information, such as phone number, account or account, we will contact you as soon as possible and provide the detailed information you need.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Auto Clutch Bearing |

|---|---|

| Material: | Chrome Steel |

| Tolerance: | P5 |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Contribution of Linear Bearings to CNC Machining Efficiency and Accuracy

Linear bearings play a crucial role in enhancing the efficiency and accuracy of Computer Numerical Control (CNC) machining processes. Here’s how they contribute:

- 1. Enhanced Precision:

Linear bearings provide smooth and precise linear motion along machine axes. This precision is essential for achieving tight tolerances and accurate dimensions in machined parts.

- 2. Reduced Friction and Wear:

Low friction in linear bearings minimizes energy loss and heat generation during movement. This reduces wear on the components and extends the lifespan of the machine, resulting in consistent performance over time.

- 3. Smooth Motion Control:

Linear bearings enable controlled and predictable motion, allowing CNC machines to execute complex tool paths with smooth transitions. This is crucial for producing intricate shapes and achieving high-quality surface finishes.

- 4. Minimized Vibration and Noise:

The smooth operation of linear bearings reduces vibration and noise levels during machining. This is especially important for maintaining a stable machining environment and producing parts with minimal surface imperfections.

- 5. Rapid Traverse Speeds:

Linear bearings facilitate rapid movements of machine components between machining operations. This increases the efficiency of the machining process, reducing cycle times and increasing overall productivity.

- 6. High Acceleration and Deceleration:

Linear bearings allow CNC machines to accelerate and decelerate rapidly without sacrificing precision. This capability is advantageous for optimizing machining time while maintaining accuracy.

- 7. Improved Repeatability:

Linear bearings ensure consistent and repeatable motion, resulting in parts that match design specifications precisely across multiple production runs.

- 8. Flexibility in Design:

Linear bearings enable the design of compact and space-efficient CNC machines. Their small footprint allows for more efficient use of manufacturing floor space.

In summary, linear bearings significantly enhance CNC machining by providing accurate, smooth, and controlled motion. This translates into higher precision, reduced wear, improved surface finishes, and increased productivity. Whether it’s milling, turning, or other CNC processes, linear bearings are essential for achieving the level of accuracy and efficiency demanded by modern manufacturing.

Recent Advancements in Linear Bearing Technology

Recent years have seen significant advancements in linear bearing technology, leading to improved performance, reliability, and versatility. Some notable developments include:

- Nanotechnology: The integration of nanotechnology has allowed for the development of ultra-precision linear bearings with nanometer-scale accuracy. These bearings are ideal for applications requiring extremely fine movement and positioning.

- Smart Bearings: Advances in sensor technology have enabled the creation of smart linear bearings that can monitor parameters like temperature, load, and vibration in real time. This data helps in predictive maintenance and optimizing operational efficiency.

- Materials Innovation: New materials with enhanced properties, such as self-lubricating and corrosion-resistant coatings, have extended the lifespan of linear bearings and reduced the need for frequent lubrication and maintenance.

- Compact Designs: Manufacturers are designing more compact linear bearings to suit space-constrained applications while maintaining high load capacity and precision.

- Environmental Sustainability: There’s a growing emphasis on developing linear bearings with reduced environmental impact, including using eco-friendly materials and designs that require less energy to operate.

- Integration of IoT: Linear bearings are being integrated into the Internet of Things (IoT) networks, allowing them to communicate with other equipment and systems for seamless automation and optimization.

- Magnetic Levitation Bearings: Magnetic levitation (maglev) technology is being applied to linear bearings to create frictionless movement, reducing wear and enabling smoother and more precise motion.

- Advanced Coatings: Coatings with enhanced wear resistance, low friction, and improved thermal properties are being applied to linear bearings, extending their service life in challenging environments.

These advancements have contributed to the expanding range of applications where linear bearings can be used, from aerospace and automotive industries to medical devices and consumer electronics. As technology continues to evolve, linear bearings will play a crucial role in enabling more efficient and precise motion control across various sectors.

Common Applications and Industries for Linear Bearings

Linear bearings find widespread use in a variety of applications and industries due to their ability to provide controlled linear motion. Some common applications and industries where linear bearings are essential components include:

- Industrial Automation:

Linear bearings are used in automated machinery and equipment to enable precise and repeatable movement of components. They play a critical role in assembly lines, material handling systems, and robotics.

- CNC Machinery:

In computer numerical control (CNC) machines, linear bearings facilitate accurate movement of the cutting tool or workpiece. They contribute to the precision and quality of machining operations.

- Medical Devices:

Linear bearings are crucial in medical equipment such as MRI machines, CT scanners, and robotic surgical systems. Their precision and smooth motion are vital for accurate medical procedures.

- Packaging Machinery:

In packaging and labeling machines, linear bearings ensure precise movement of containers, products, and labeling mechanisms. This results in consistent and reliable packaging processes.

- Printing Industry:

Linear bearings are used in printing presses to ensure precise movement of print heads, paper feed mechanisms, and other critical components. This helps achieve accurate printing results.

- Textile Machinery:

In textile manufacturing, linear bearings contribute to the smooth operation of spinning machines, looms, and fabric handling systems. They help maintain proper tension and alignment of materials.

- Aerospace and Defense:

Linear bearings are utilized in aerospace applications such as aircraft actuators, landing gear systems, and satellite mechanisms. They withstand harsh conditions and provide reliable motion control.

- Material Handling:

In conveyor systems and material handling equipment, linear bearings facilitate the movement of goods along production lines, warehouses, and distribution centers.

- Automotive Industry:

Linear bearings are used in automotive manufacturing for tasks like seat adjustments, sunroof operation, and door mechanisms. Their precision enhances passenger comfort.

- Scientific Research:

In laboratory equipment and scientific instruments, linear bearings contribute to accurate positioning of samples, sensors, and analytical components.

These are just a few examples of the diverse applications and industries where linear bearings are essential. Their ability to provide controlled and reliable linear motion makes them indispensable in achieving precision, efficiency, and performance across various sectors.

editor by CX 2024-04-17

China best 30308/30309/30310/30311/30312 Tapered Roller/thrust/china wholesale/Engine/motorcycle/tractor/linear guide/steel ball/Diesel generator sets/gear/1688 bearing deep groove ball bearing

Product Description

Product Parameters

| Tapered Roller Bearing | ||||||||||||||

| Single Row Tapered Roller Bearing | ||||||||||||||

| Bearing No. | dxDxTxBxC (mm) | Weight(kg) | Bearing No. | dxDxTxBxC (mm) | Weight(kg) | |||||||||

| 35712 | 15 | 35 | 12 | 7 | 5 | 0.050 | 30302 | 15 | 42 | 14.25 | 13 | 11 | 0.098 | |

| 35713 | 17 | 40 | 13.25 | 12 | 11 | 0.080 | 30303 | 17 | 47 | 15.25 | 14 | 12 | 0.134 | |

| 35714 | 20 | 47 | 15.25 | 14 | 12 | 0.127 | 30304 | 20 | 52 | 16.25 | 16 | 13 | 0.176 | |

| 35715 | 25 | 52 | 16.25 | 15 | 13 | 0.154 | 30305 | 25 | 62 | 18.25 | 17 | 15 | 0.272 | |

| 35716 | 30 | 62 | 17.25 | 16 | 14 | 0.241 | 30306 | 30 | 72 | 20.75 | 19 | 16 | 0.408 | |

| 35717 | 35 | 72 | 18.25 | 17 | 15 | 0.344 | 30307 | 35 | 80 | 22.75 | 21 | 18 | 0.540 | |

| 35718 | 40 | 80 | 19.75 | 18 | 16 | 0.435 | 30308 | 40 | 90 | 25.25 | 23 | 20 | 0.769 | |

| 35719 | 45 | 85 | 20.75 | 19 | 16 | 0.495 | 30309 | 45 | 100 | 27.25 | 25 | 22 | 1.571 | |

| 35710 | 50 | 90 | 21.75 | 20 | 17 | 0.563 | 3571 | 50 | 110 | 29.25 | 27 | 23 | 1.310 | |

| 35712 | 60 | 110 | 23.75 | 22 | 19 | 0.949 | 3571 | 55 | 120 | 31.5 | 29 | 25 | 1.660 | |

| 35713 | 65 | 120 | 24.75 | 23 | 20 | 1.180 | 3571 | 65 | 140 | 36 | 33 | 28 | 2.550 | |

| 35714 | 70 | 125 | 26.25 | 24 | 21 | 1.260 | 3571 | 70 | 150 | 38 | 35 | 30 | 3.060 | |

| 35715 | 75 | 130 | 27.25 | 25 | 22 | 1.410 | 3571 | 75 | 160 | 40 | 37 | 31 | 3.570 | |

| 35716 | 80 | 140 | 28.25 | 26 | 22 | 1.720 | 3 0571 | 80 | 170 | 42.5 | 39 | 33 | 4.410 | |

| 35717 | 85 | 150 | 30.5 | 28 | 24 | 2.140 | 3 0571 | 85 | 180 | 44.5 | 41 | 34 | 5.200 | |

| 35718 | 90 | 160 | 32.5 | 30 | 26 | 2.660 | 3 0571 | 90 | 190 | 46.5 | 43 | 36 | 6.030 | |

| 35719 | 95 | 170 | 34.5 | 32 | 27 | 3.070 | 3571 | 95 | 200 | 49.5 | 45 | 38 | 6.980 | |

| 35710 | 100 | 180 | 37 | 34 | 29 | 3.780 | 30320 | 100 | 215 | 51.5 | 47 | 39 | 8.560 | |

| 31305 | 25 | 62 | 18.25 | 17 | 13 | 0.284 | ||||||||

| 31306 | 30 | 72 | 20.75 | 19 | 14 | 0.398 | ||||||||

| 31307 | 35 | 80 | 22.75 | 21 | 15 | 0.530 | ||||||||

| 31308 | 40 | 90 | 25.25 | 23 | 17 | 0.738 | ||||||||

| 31311 | 55 | 120 | 31.5 | 29 | 21 | 1.590 | ||||||||

| 31313 | 65 | 140 | 36 | 33 | 23 | 2.420 | ||||||||

| 31314 | 70 | 150 | 38 | 35 | 25 | 2.920 | ||||||||

| 31315 | 75 | 160 | 40 | 37 | 26 | 3.470 | ||||||||

| 31316 | 80 | 170 | 42.5 | 39 | 27 | 4.110 | ||||||||

| 31317 | 85 | 180 | 44.5 | 41 | 28 | 4.850 | ||||||||

| 31318 | 90 | 190 | 46.5 | 43 | 30 | 5.660 | ||||||||

| 31320 | 100 | 215 | 56.5 | 51 | 35 | 8.670 | ||||||||

01 Roller Bearing

| Cylindrical Roller Bearings | Spherical Roller Bearings |

| Taper Roller Bearings | Needle Roller Bearings |

02 Applications

| Main Applications | |

| Automobile | Others |

| Front Wheel | Machine Tool Spindles |

| Rear Wheel | Construction Machinery |

| Gearbox | Large Agricultural Machinery |

| Differential Pinion Shaft | Railroad Vehicle Gear Reducers |

| Mill Spokes And Reducers | |

| ***Suitable for Heavy Loads and Shock Loads*** | |

Packaging & Shipping

Company Profile

About Us

Focus on a variety of industries

Provide maintenance solutions

Optimize customer inventory and reduce cost

What We Do

Comprehensive product range:

– Bearings

– Oil seals, Transmission belt

– Chain and Sprocket

– Hub assembly & Wheel bearings

– Coupling, castings

– Linear motion

Our Advantages

1. We have the most advanced bearing process equipment, CNC automatic facilities, and testing instruments.

2. We manufacture ball bearings and mounted bearing units, and also provide a strong full range of products, including electric motors and components One-stop partnerships products from our audited supply chain.

3. All products are manufactured exclusively by companies with ISO 9001:2008 certified Quality Systems which use state-of-the-art machines. The quality path starts from the beginning to deliver and goods’ quality trackable

| Advantage | |

| Advanced Automatic Lines | Comprehensive Range |

| Premium Quality | Sustainability |

Our Values

Behavior-based, service-oriented, focused on results and committed to continuous improvement

Factory

To be a leader in providing the best valuable (Reasonable cost, Reliable quality) supply of precision rollers.

Providing this value, will help our customers remain competitive in the global marketplace.

Please see detailed introduction about our manufacturing process and measuring process.

Advantage Manufacturing Processes and Quality Control:

01Heat Treatment

02 Centerless Grinding Machine 11200 (most advanced)

03 Automatic Production Lines for Raceway

04 Automatic Production Lines for Raceway

05 Ultrasonic Cleaning of Rings

06 Automatic Assembly

07 Ultrasonic Cleaning of Bearings

08 Automatic Greasing, Seals Pressing

09Measurement of Bearing Vibration (Acceleration)

10 Measurement of Bearing Vibration (Speed)

11 Laser Marking

12 Automatic Packing

Quality Warranty

Granville as a manufacturer of high quality products, guarantees compliance with the highest standards relative to the use of the best steel quality in the production process, the highest standards in the design of contact surfaces, as well as the most efficient packing and lubrication of parts. From material coming, quality control through all processes. Except interal test, goods to third party inspection if required. After the center of inspection and experiment being founded, effective methods of inspecting all kinds of raw materials are mastered and then the reliability of bearings is ensured. One of our main objectives is the continued improvement in the quality of our products and processes, in pursuit of which we obtained ISO certification 9001:2008 and TS16949.

After Sales Service

- Optimize customer inventory and reduce cost

- Provide maintenance solutions

FAQ

Q1.Can you accept OEM and customization?

A: Yes. We can customize it according to the samples and drawings you provide.

Q2.Do you keep a stock of these things?

A: In stocks

Q3.Can you provide samples free of charge?

A: Yes. We can provide samples free of charge. But the freight is paid by the customer.

Q4.What’s the delivery date?

A:The delivery time of sample orders is 3 working days.The bulk orders are 5-10 working days.

Q5: Why your price is higher than others?

A: Price = quality . We firmly believe that by the quality of the customer is always get more reliable than on price . So we insist on doing high-quality products.

Q6:What kind of transport do you have ?

A: According to the weight,we will choose the most appropriate mode of transport for you. Our freight forwarding is efficient and cheap.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Small and Medium-Sized (60-115mm) |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | Order Sample Sample unit price depends on the specific model

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Considerations for Selecting the Right Type and Size of Linear Bearing

Choosing the appropriate type and size of linear bearing requires careful consideration of various factors to ensure optimal performance and compatibility with the application. Here are important considerations to keep in mind:

- 1. Load Capacity:

Determine the maximum load the linear bearing will need to support. Consider both static and dynamic loads to select a bearing that can handle the expected weight and forces.

- 2. Speed and Acceleration:

Assess the required speed and acceleration of the linear motion. Different linear bearing types have different speed limitations, so choose one that can accommodate the desired motion profile.

- 3. Precision and Accuracy:

If your application requires precise positioning, choose linear bearings that offer high accuracy and repeatability. Linear ball bearings are known for their precision, while linear roller bearings offer higher load capacity.

- 4. Environment:

Consider the operating environment, including temperature, humidity, dust, and potential exposure to chemicals. Select linear bearings that are designed to withstand the specific environmental conditions.

- 5. Rail or Shaft Compatibility:

Ensure that the chosen linear bearing is compatible with the rail or shaft you intend to use. Proper fit and alignment are crucial for smooth motion and long bearing life.

- 6. Space Constraints:

If your application has limited space, choose compact linear bearings that can fit within the available area without compromising performance.

- 7. Maintenance Requirements:

Consider the level of maintenance your application can accommodate. Some linear bearings are self-lubricating, reducing the need for frequent maintenance.

- 8. Noise Level:

For noise-sensitive environments, opt for linear bearings that provide quiet operation to avoid disruptions caused by excessive noise.

- 9. Mounting Options:

Consider how the linear bearing will be mounted and integrated into your system. Different bearings may require specific mounting configurations.

- 10. Cost and Budget:

Balance the desired features and performance with your budget constraints. While high-performance linear bearings may offer advanced features, they can also come at a higher cost.

By carefully evaluating these factors, you can choose the most suitable type and size of linear bearing for your specific application. Consulting with bearing manufacturers and engineers can also provide valuable insights to ensure the optimal selection.

Advancements in Linear Bearing Technology

Recent years have witnessed significant advancements in linear bearing technology, leading to improved performance and expanded applications. Some notable advancements include:

- Rolling Element Innovations:

Manufacturers are introducing new types of rolling elements, such as ceramic balls and specialized coatings, to enhance load capacity, reduce friction, and extend the lifespan of linear bearings.

- Lubrication Solutions:

Advanced lubrication techniques, including self-lubricating materials and greases with extended lifetimes, are being developed to optimize the performance of linear bearings while reducing maintenance needs.

- Smart and Sensor-Integrated Bearings:

Linear bearings with built-in sensors provide real-time data on temperature, vibration, and wear. This enables predictive maintenance, early fault detection, and optimization of bearing performance.

- Improved Corrosion Resistance:

New materials and coatings are being employed to enhance the corrosion resistance of linear bearings. This is particularly beneficial in environments where exposure to moisture and corrosive substances is a concern.

- Reduced Friction and Energy Consumption:

Advanced engineering and design techniques are leading to lower friction coefficients and reduced energy consumption in linear bearings. This not only improves efficiency but also contributes to sustainability efforts.

- High-Speed Capabilities:

Linear bearings capable of operating at higher speeds are being developed to meet the demands of applications requiring rapid and precise movements, such as in the semiconductor and electronics industries.

- Enhanced Sealing and Contaminant Management:

New sealing technologies are being employed to provide better protection against contaminants and debris. This is critical for applications where cleanliness is paramount.

- Integration with Industry 4.0:

Linear bearings are increasingly designed to be compatible with Industry 4.0 principles, allowing them to be integrated into digital manufacturing and automation systems for improved overall efficiency.

- Material Advancements:

Novel materials with improved mechanical properties, wear resistance, and temperature tolerance are being used in the production of linear bearings, expanding their operating capabilities.

These recent advancements in linear bearing technology are enabling industries to achieve higher levels of precision, efficiency, reliability, and predictive maintenance, making linear bearings an essential component of modern machinery and systems.

Linear Bearings: Definition and Applications

Linear bearings are mechanical components designed to facilitate smooth and controlled linear motion in a single direction. They are widely used across various industries to provide precise movement and guidance in applications where traditional rotary bearings are not suitable. Linear bearings offer several advantages and find use in a diverse range of applications:

- Precision Machinery:

Linear bearings are a fundamental part of precision machinery such as CNC machines, laser cutting equipment, and coordinate measuring machines. They ensure accurate movement and positioning of tools and components, enabling high-quality and intricate work.

- Industrial Automation:

In automated manufacturing and assembly lines, linear bearings play a critical role in moving robotic arms, conveyors, and various stages along predefined paths. Their ability to provide smooth and repeatable motion contributes to increased production efficiency.

- Medical Devices:

Linear bearings are essential in medical devices like diagnostic machines, imaging systems, and robotic surgical equipment. They enable precise movement and positioning required for accurate diagnoses and minimally invasive procedures.

- Packaging Machinery:

In packaging industries, linear bearings guide the motion of conveyor belts, sealing mechanisms, and labeling devices. These bearings ensure consistent and reliable packaging processes.

- Material Handling:

Linear bearings are used in various material handling equipment such as pick-and-place systems, automated warehouses, and sorting machines. They enable efficient movement of goods and materials with reduced friction and wear.

- Semiconductor Manufacturing:

In semiconductor fabrication, where extreme precision is crucial, linear bearings are employed in wafer handling, chip assembly, and inspection equipment. They ensure contamination-free motion and positioning of delicate components.

- Textile Machinery:

Textile machines use linear bearings for guiding yarn paths, thread tensioning, and controlling the movement of fabric during weaving and knitting. These bearings contribute to the quality and efficiency of textile production.

- Automotive Manufacturing:

Linear bearings are found in automotive assembly lines for tasks such as welding, painting, and component installation. They provide accurate movement and positioning of vehicle parts, contributing to the production process.

- Aerospace and Defense:

In aerospace applications, linear bearings are used in various mechanisms, including aircraft seats, control surfaces, and satellite deployment systems. Their reliability and precision are crucial in these demanding environments.

- Renewable Energy:

In wind turbines and solar panel manufacturing, linear bearings are used to adjust the positioning of blades, solar panels, and tracking systems. They contribute to the efficiency of renewable energy generation.

Overall, linear bearings offer precise, controlled, and smooth linear motion in diverse applications across industries. Their ability to guide and support loads while minimizing friction and wear makes them essential components for achieving accurate movement and improved operational efficiency.

editor by CX 2024-04-09

China wholesaler Industrial Automation High Precision Linear Bearing for Replacement CZPT Linear Transmission deep groove ball bearing

Product Description

Industrial Automation High Precision Linear Bearing for replacement Hiwin linear transmission: high-torque SG serias

Our Partners

FAQ

Q: Could you provide sample?

A: Yes,we could .

Q: What is your MOQ?

A: 1 pc is available.

Q: Do you have any replaceable types of Hiwin, THK, IKO,etc?

A: Yes, we will check our replaceable types as per Hiwin, THK,IKO and other brands types.

Q: What is your delivery time ?

A: About 5-7 days after receiving the payment.

Q:Is customization available?

A:Yes.Our customized service is available.

Our Commitments

— All products have passed rigorous factory test to ensure high quality.

— We own patented products and SGS,ISO certifications.

— High-efficiency assembly and production lines ensure on-time delivery.

Detailed Photos

Company Profile

Certifications

Exhitions

Application

Our Advantages

Pre sale service:

▽ Technical communication with engineer.

▽ Factory visit.

▽ Making customized drawings patiently.

After sale service:

▽ Overseas and spare part support.

▽ Technical and spare parts support.

▽ ODM, OEM service

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Warehouse Crane, Shipboard Crane, Goods Yard Crane, Building Crane, Workshop Crane |

|---|---|

| Material: | Steel |

| Driven Type: | Hydraulic |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample 290000PCS/Month

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Challenges and Solutions for Addressing Friction and Wear in Linear Bearings

Friction and wear are common challenges in linear bearings that can impact their performance and lifespan. Here are the challenges and some solutions to address them:

- 1. Challenge: Friction:

Friction between the bearing components can lead to increased energy consumption, heat generation, and reduced efficiency.

- Solution: Lubrication:

Proper lubrication is essential to minimize friction. Lubricants reduce the contact between moving parts, allowing smoother motion and reducing wear. Choosing the right lubricant and applying it correctly can significantly mitigate friction-related issues.

- 2. Challenge: Wear:

Continuous movement can lead to wear on the bearing surfaces, affecting precision and performance over time.

- Solution: Regular Maintenance:

Implementing a regular maintenance schedule can help monitor wear and replace worn components before they compromise performance. This includes cleaning, re-lubrication, and periodic inspection of the bearing’s condition.

- 3. Challenge: Contaminants:

Dust, debris, and foreign particles can enter the bearing system, leading to increased friction and accelerated wear.

- Solution: Sealing and Protection:

Using seals, covers, or protective enclosures can help prevent contaminants from entering the bearing system. These protective measures maintain the integrity of the lubricant and extend the bearing’s lifespan.

- 4. Challenge: Improper Installation:

If linear bearings are not installed correctly, misalignment and uneven load distribution can contribute to friction and wear.

- Solution: Precise Installation:

Follow manufacturer guidelines for proper installation, ensuring accurate alignment and even load distribution. This reduces the risk of premature wear and ensures optimal performance.

- 5. Challenge: Inadequate Lubrication:

If the linear bearings are under-lubricated or over-lubricated, it can lead to increased friction and wear.

- Solution: Lubrication Management:

Monitor and manage lubrication levels to ensure they are within the recommended range. Regularly assess the lubricant’s condition and replenish as needed to maintain optimal performance.

- 6. Challenge: High Loads and Speeds:

High loads and speeds can increase friction and wear on linear bearings.

- Solution: Proper Selection:

Select linear bearings that are designed to handle the specific loads and speeds of the application. This ensures that the bearings can operate effectively under the given conditions.

Addressing friction and wear challenges in linear bearings requires a combination of proper maintenance practices, appropriate lubrication, protective measures, and careful selection of bearings. By implementing these solutions, the performance and longevity of linear bearings can be optimized.

Recent Advancements in Linear Bearing Technology

Recent years have seen significant advancements in linear bearing technology, leading to improved performance, reliability, and versatility. Some notable developments include:

- Nanotechnology: The integration of nanotechnology has allowed for the development of ultra-precision linear bearings with nanometer-scale accuracy. These bearings are ideal for applications requiring extremely fine movement and positioning.

- Smart Bearings: Advances in sensor technology have enabled the creation of smart linear bearings that can monitor parameters like temperature, load, and vibration in real time. This data helps in predictive maintenance and optimizing operational efficiency.

- Materials Innovation: New materials with enhanced properties, such as self-lubricating and corrosion-resistant coatings, have extended the lifespan of linear bearings and reduced the need for frequent lubrication and maintenance.

- Compact Designs: Manufacturers are designing more compact linear bearings to suit space-constrained applications while maintaining high load capacity and precision.

- Environmental Sustainability: There’s a growing emphasis on developing linear bearings with reduced environmental impact, including using eco-friendly materials and designs that require less energy to operate.

- Integration of IoT: Linear bearings are being integrated into the Internet of Things (IoT) networks, allowing them to communicate with other equipment and systems for seamless automation and optimization.

- Magnetic Levitation Bearings: Magnetic levitation (maglev) technology is being applied to linear bearings to create frictionless movement, reducing wear and enabling smoother and more precise motion.

- Advanced Coatings: Coatings with enhanced wear resistance, low friction, and improved thermal properties are being applied to linear bearings, extending their service life in challenging environments.

These advancements have contributed to the expanding range of applications where linear bearings can be used, from aerospace and automotive industries to medical devices and consumer electronics. As technology continues to evolve, linear bearings will play a crucial role in enabling more efficient and precise motion control across various sectors.

Advantages of Linear Bearings over Other Bearing Types

Linear bearings offer several distinct advantages when compared to other types of bearings, particularly in applications that require controlled linear motion. These benefits contribute to their widespread use across various industries:

- Precise Linear Motion:

Linear bearings are designed specifically for linear motion, providing accurate and controlled movement along a defined path. This precision is essential in applications that demand accurate positioning and repeatability.

- Low Friction:

Linear bearings are designed to minimize friction during motion. The reduced friction translates to smoother movement, reduced wear, and improved efficiency, making them suitable for applications requiring consistent motion.

- High Load Capacity:

Linear bearings can handle significant loads in both radial and axial directions. This capability allows them to support heavy components and maintain stability under various loads.

- Minimal Maintenance:

Due to their design and minimal contact between moving parts, linear bearings require less maintenance compared to other types of bearings. This is particularly advantageous in hard-to-reach or inaccessible areas.

- Guided Motion:

Linear bearings provide guided and constrained motion along a single axis. This guidance eliminates the need for complex guiding mechanisms, reducing design complexity and simplifying assembly.

- Compact Design:

Linear bearings have a compact form factor, making them suitable for applications with limited space. Their small footprint allows for efficient use of available area.

- Low Noise and Vibration:

Linear bearings generate minimal noise and vibration during operation, contributing to quieter and more comfortable working environments in applications such as medical devices and precision machinery.

- Smooth Movement:

Linear bearings offer smooth and consistent movement, essential for applications requiring continuous and controlled motion, such as robotic systems and conveyor belts.

- Customization:

Linear bearings can be designed to fit specific application requirements, including load capacity, travel distance, and environmental conditions. This customization enhances their suitability for diverse applications.

- Reduced Wear:

The low friction and guided motion of linear bearings result in reduced wear on both the bearing and the mating surface, leading to longer service life and reduced maintenance costs.

Overall, the benefits of using linear bearings make them a preferred choice in applications that demand accurate linear motion, efficient load handling, and reduced maintenance. Their ability to deliver precision, stability, and reliability contributes to improved performance across various industries.

editor by CX 2024-04-04

China supplier Slewing Bearing Tapered Roller Steel Ball Bearings Deep Groove Puller Front Wheel Hub Pillow Block Taper Roller Angular Contact Rear Wheel Linear Auto Bearing supplier

Product Description

Slewing bearing Tapered Roller steel ball bearings Deep Groove puller front wheel hub pillow block taper roller angular contact rear wheel linear auto bearing

Application of Slewing bearing

A slewing bearing, also called a turntable bearing, is a type of bearing that allows for a heavy but slow-turning or slowly-oscillating load to be supported in combination (axial, radial and moment loads), often a horizontal platform such as a conventional crane, a swing yarder, or the wind-facing platform of a horizontal-axis (yaw) windmill. In other orientations (e.g. a horizontal axis of rotation) they are used in materials handling grapples, forklift attachments, welding turnover jigs and so on.

Slewing rings range in size from as little as 100mm diameter to well over 15 000mm (often segmented at this size for easy transport and handling); for example the bearings on the Falkirk Wheel are 4 meters diameter and fit over a 3.5 meter axle. Slewing bearings are often made with gear teeth integral with the inner or outer race (or both in rare cases) used to drive the platform relative to the base (for example in winches).

Slewing rings are used in a variety of applications, including: