Product Description

Product Description

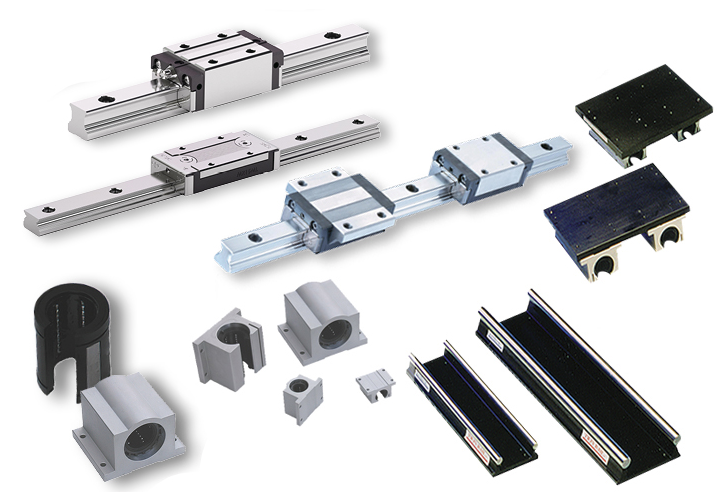

- Bearing structure: consists of outer cylinder, retainer, balls, side seals;

- Premium grade raw material: GCr15 bearing steel cylinder, G10 class precision ball, PA66 plastic retainer;

- Cylinder metal body is heat treated and hardened to enhance to the rigidity and working life;

- Both the inner bore and outer cylinder surface are ground several procedures to guarantee the precision;

- Completely washed by the super sonic washing machine, pre-lubricated;

- Main features: high precision and rigidity, low friction, ease of assembly and replacement, good interchangeability;

- Good quality at affordable rates, price is very economic and nice;

- Ideal transmission component for linear motion movement, widely used in CNC machines, factory automation, industrial machines, electric tools, textile machines, fitting equipment, etc.;

- Wide size range for option, models including(special size has to be customized):

LM3, LM4, LM5UU, LM6UU, LM8SUU, LM8UU, LM10UU, LM12UU, LM13UU, LM16UU, LM20UU, LM25UU, LM30UU, LM35UU, LM40UU, LM50UU, LM60UU, LM80UU, LM100UU, LM120UU, LM150UU, etc.

Product Parameters

Detailed Photos

Certifications

Packaging & Shipping

1.According to the quantity and the ship method of your order, we will choose the best packing ways.

2.For example, if the products shipped by TNT,DHL,FedEx, the goods would be packed by paper carton for economic delivery. As bulk order shipped by sea, the goods would be packed by wooden carton.

Our Advantages

FAQ

DO NOT worry about PRICE, we are manufacturer.

DO NOT worry about QUALITY, we have 16 years experience.

DO NOT worry about AFTER-SALES, we are 24 hours online.

Q1:Who we are?

We are the factory based in ZHangZhoug,China,start from 2007 sell to all over the.world.the factory area is around 45000 square meters.we have 900 employees.

Q2: Do you have a catalogue?

Can you send me the catalogue to have a check of all your products?

A: Yes , We have product catalogue.Please contact us on line or send an Email to sending the catalogue.

Q3: I can’t find the product on your catalogue, can you make this product for me?

A: Our catalogue shows most of our products,but not all.So just let us know what product do you need.

Q4 : Can you make customized products and customized packing?

A: Yes.We made a lot of customized products for our customer before.And we have many moulds for our customers already.About customized packing,we can put your Logo or other info on the packing.There is no problem.

Q5: Can you provide samples ? Are the samples free ?

A: Yes,we can provide samples.Normally,we provide 1-2pcs free samples for test or quality checking.But you have to pay for the

shipping cos.If you need many items, or need more qty for each item,we will charge for the samples.

Any requirements or question,Welcome to “Send” us an e-mail Now!

Recommend product

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Magnetically, Corrosion Resistant, High Speed, High Precision |

|---|---|

| Function: | Super |

| Flange Shape: | Oval |

| Shape: | Flange |

| Series: | LM |

| Material: | Bearing Steel |

| Samples: |

US$ 16.8/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Differences between Open-Type and Closed-Type Linear Bearings

Open-type and closed-type linear bearings are two common variations used in linear motion systems, each with its own advantages and considerations:

- 1. Open-Type Linear Bearings:

Open-type linear bearings, as the name suggests, have an open design that allows easy access to the bearing’s rolling elements and raceways. These bearings are characterized by:

- Quick Maintenance: Open-type bearings are easier to clean, lubricate, and inspect due to their open structure, making maintenance more convenient.

- Increased Contamination Risk: Because they are exposed, open-type bearings are more susceptible to dust, debris, and contamination, which can affect their performance and lifespan.

- 2. Closed-Type Linear Bearings:

Closed-type linear bearings are enclosed within a housing or carriage that provides protection from external elements. These bearings offer the following features:

- Enhanced Contamination Protection: Closed-type bearings are less vulnerable to contaminants and offer improved protection against dust, dirt, and debris, leading to longer service life.

- Reduced Accessibility: Maintenance and inspection of closed-type bearings might be more complex due to the need to disassemble the housing or carriage for access.

- Reduced Noise: The enclosed design of closed-type bearings can contribute to reduced noise levels, which is advantageous in noise-sensitive applications.

Choosing between open-type and closed-type linear bearings depends on the specific requirements of the application. If easy maintenance and accessibility are crucial, open-type bearings might be preferred. On the other hand, closed-type bearings offer better protection against contaminants and reduced noise, making them suitable for environments where cleanliness and quiet operation are essential.

Contribution of Linear Bearings to Smooth Movement of Conveyors and Linear Slides

Linear bearings play a crucial role in ensuring the smooth movement of industrial conveyors and linear slides by providing low-friction support and guiding mechanisms. Here’s how linear bearings contribute to their operation:

- Smooth Motion: Linear bearings offer precise and smooth linear motion to conveyors and linear slides, allowing materials or objects to move seamlessly along a defined path.

- Low Friction: The design of linear bearings minimizes friction between the moving parts, reducing energy consumption and wear. This is particularly important for conveyors and slides that require frequent and continuous movement.

- Guidance: Linear bearings guide the movement of the conveyor belts or linear slides, ensuring that they stay on track and follow the desired path without deviation.

- Load Support: Linear bearings provide support for both radial and axial loads, allowing conveyors to carry heavy loads and linear slides to accommodate objects or components without sacrificing smoothness.

- Precision: Linear bearings offer high precision and accuracy, which is essential for applications where precise positioning is required, such as in automated manufacturing processes.

- Reduced Noise and Vibration: Linear bearings contribute to quieter operation by reducing noise and absorbing vibrations generated during movement. This is beneficial in environments where noise reduction is important.

- Longevity: By minimizing friction and wear, linear bearings enhance the longevity of conveyors and linear slides, reducing the need for frequent maintenance and replacement.

In industrial settings, linear bearings ensure that conveyors efficiently transport materials, products, or components, while linear slides provide controlled and accurate movement for various applications. Whether in manufacturing, logistics, or automation, the use of linear bearings results in enhanced efficiency, reduced downtime, and improved overall performance.

Design Principles and Functionalities of Linear Bearings

Linear bearings are designed with specific principles to facilitate controlled linear motion along a single axis. These design principles contribute to their functionalities, making them essential components in various applications:

- Rolling Elements:

Linear bearings typically feature rolling elements, such as balls or rollers, that move along a track or rail. These rolling elements reduce friction and enable smooth linear motion.

- Guiding Mechanism:

Linear bearings incorporate a guiding mechanism to constrain the motion to a single axis. This guiding mechanism ensures that the linear bearing moves precisely along the desired path.

- Load Distribution:

The design of linear bearings allows for effective distribution of loads, both in the radial and axial directions. This load distribution ensures stability and prevents excessive stress on individual components.

- Rail or Track:

Linear bearings typically run along a rail or track that provides a smooth and accurate path for the rolling elements. The rail is designed to resist wear and maintain its precision over time.

- Cage or Carriage:

Linear bearings use a cage or carriage to house the rolling elements and maintain their proper spacing. This arrangement ensures even load distribution and smooth movement.

- Sealing and Lubrication:

Linear bearings often incorporate sealing mechanisms to protect the rolling elements from contaminants and to retain lubrication. Proper lubrication ensures smooth motion and extends the bearing’s lifespan.

- Mounting Options:

Linear bearings are designed to be mounted in various ways, depending on the application’s requirements. Mounting options include flange-mounted, base-mounted, or end-supported configurations.

- Adjustability:

Many linear bearings are designed with provisions for adjustment, allowing users to fine-tune the preload or clearance to optimize performance and minimize play.

- Materials:

Linear bearings are constructed from materials that offer high wear resistance, durability, and corrosion resistance. Common materials include steel, stainless steel, and various engineering plastics.

- Accessories:

Accessories such as end caps, seals, and lubrication systems can enhance the functionality and lifespan of linear bearings by providing protection and ensuring proper maintenance.

Functionalities of linear bearings include providing precise linear motion, guiding components along a defined path, minimizing friction, distributing loads, and maintaining stability. The design principles ensure reliable operation and make linear bearings indispensable in applications requiring controlled and accurate linear motion.

editor by CX 2024-05-14

China Good quality Precision All Series Lm Linear Motion Ball Sliding Bearing for Shafts bearing air

Product Description

Company Profile

MKS Hydraulics ZheJiang Co., Ltd.is a scientific and professional bearing producing enterprise, gathering R&D, producing and sales as 1 integration.mainly operating on non-standard, special andgeneral bearings.

The company is especially focusing on the research and manufacture of general high-tech production with the 20 years R&D experience, professional R&D staff and advanced equipment, of which 8 sets are imported equipment and 40 sets are high-precision processing equipment. it has invested for building a modern workshop, including 1 Bainite heat processing workshop of world advanced level, 1 machine processing workshop, 2 moder thermostatic &no-dust roller grinders, assembly workshop, physical-chemical testing center, heating laboratory and moder-managed warehouse. Depending on the markets in China and abroad, the company puts an active attitude upon products R&D, resulting a healthy circulation of 1 development generation, 1 reserve generation, and 1 producion generation. The enterprise enlarges the R&D investment, creates own brand, and strives to increase the exporting products of high-tech & high value-added, gains the honorable sales result and grows into 1 of the largest R&D enterprise in China of non-standard bearing and special bearing.

The advanced technology, outstanding quaity and considerable service after sales with enthusiasm make us get the rapid development in quite short time of years, and now it becomes the largest developing and producing enterprise in Asia of concrete carrier truck, speed-reducing machine,mine-digging machine, hydraulic pump spindle bearing and crecent bearing. With the continuing and wholly new developing theory of Technology is the motivation and quality is the life, We are not only pursuing the leading position in China, but also determined to march into the worldwide bearing area during it developing process, The products are mainly applied on the industries of mine, metalurgy, engineering, machineny, machine tool,electronic machine and so on, The products have gained the excllent sales resul in the markets of Europe, Southeast Asia, Middle East and so on in a dozen of countries and areas.

Company Environment

Company Advantages

Packaging & Shipping

FAQ

1. how can we guarantee quality?

Always final Inspection before shipment;

2.what can you buy from us?

Auto Bearing,Bearing Housing,Taper Roller Bearing,Casting,Hydraulic pump,Hydraulic parts,excavator parts and so on.

Ceep groove ball bearing/Self aligning ball bearing/Cylindrical roller bearing/Spherical roller bearing/ Angular contact ball bearing/Tapered roller bearing/ Thrust ball bearing/Thrust cylindrical roller bearing/Needle roller bearing

3. why should you buy from us not from other suppliers?

One stop bearing and mechanical customized parts,

Designed bearing,

Small quantity order available

Factory price offer

OEM ODM bearing service

4.What is the transportation?

lf small quantity,we suggest to send by express,such as DHL,UPS,TNT FEDEX flarge amount,by air or sea shipping.

5.Can we design packaging?

Except regular packing,and we can make customer’s own packing.

6.What’s your payment method?

We can accept LC, T/T, D/P, PayPal, Western Union, Small-amount payment, MoneyGram etc.

7.Can the company provide free samples?

We can provide samples for free. You only need to provide shipping.

8.Is the company a production factory or a trading company?

MKS company is a manufacturing enterprise focusing on bearings ,hydraulic pumps and hydraulic parts , produce and sales.

If you have any questions,Please contact us,We must be reply quickly.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | High Speed |

|---|---|

| Function: | Ordinary |

| Flange Shape: | Cutting-Edge |

| Shape: | Straight |

| Series: | LM |

| Material: | Bearing Steel |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Differences Between Linear Ball Bearings and Linear Roller Bearings

Linear ball bearings and linear roller bearings are two distinct types of linear bearings, each with its own design and characteristics. Here’s how they differ and when they are preferred:

- 1. Design:

Linear ball bearings use ball bearings to provide rolling motion along the shaft. Linear roller bearings, on the other hand, use cylindrical or needle rollers for motion. Roller bearings have a larger contact area, distributing the load over a broader surface.

- 2. Load Capacity:

Linear roller bearings typically have a higher load-carrying capacity compared to linear ball bearings. This makes them suitable for applications with heavier loads and greater force requirements.

- 3. Friction and Smoothness:

Linear ball bearings offer lower friction and smoother motion due to the point contact between the balls and the shaft. Roller bearings may have slightly higher friction but can handle larger loads without sacrificing smoothness.

- 4. Precision and Accuracy:

Linear ball bearings are often preferred for applications requiring high precision and accuracy. Their point contact provides precise positioning and repeatability, making them suitable for tasks like CNC machining and optical systems.

- 5. Noise and Vibration:

Linear ball bearings tend to generate less noise and vibration due to their smoother rolling action. Roller bearings may produce slightly more noise but are still used in applications where noise is not a critical factor.

- 6. Speed:

Linear ball bearings are well-suited for high-speed applications due to their low friction and smooth motion. Roller bearings are also capable of high speeds but may have slightly different characteristics.

- 7. Cost:

Linear ball bearings are often more cost-effective for lower-load and precision applications. Linear roller bearings may be preferred for heavy-duty applications, which may justify their higher cost.

- 8. Application Scenarios:

Linear ball bearings are commonly used in applications where precision, smooth motion, and accuracy are paramount, such as in CNC machinery, 3D printers, and optical systems. Linear roller bearings excel in applications with higher loads, such as heavy machinery, material handling, and industrial automation.

In summary, the choice between linear ball bearings and linear roller bearings depends on the specific requirements of the application. Each type has its strengths and weaknesses, and selecting the right type ensures optimal performance and longevity.

Role of Linear Bearings in Heavy Load and High Precision Applications

Linear bearings are essential components in applications that require the combined capabilities of handling heavy loads and maintaining high precision. They serve a critical role in such scenarios:

- Heavy Load Handling:

Linear bearings are designed to support and guide heavy loads along a linear path. They distribute the weight evenly, reducing friction and wear on the moving components and ensuring smooth and stable movement.

- Precision Motion Control:

Linear bearings enable precise and accurate control over the motion of heavy loads. This precision is crucial in applications where components need to be positioned or moved with extremely fine tolerances.

- Reduced Friction:

Linear bearings are engineered to minimize friction between moving parts, even under heavy load conditions. This not only improves efficiency but also enhances the accuracy of movement.

- Smooth Movement:

Linear bearings provide smooth and consistent movement, ensuring that heavy loads can be guided and positioned without jarring or sudden stops. This is particularly important for applications requiring controlled and gentle motion.

- Reduced Wear and Maintenance:

By reducing friction and wear, linear bearings extend the operational lifespan of heavy-load equipment. This translates to lower maintenance requirements and longer intervals between servicing.

- Optimized Performance:

Linear bearings contribute to the overall performance of heavy-load systems by allowing them to operate smoothly, accurately, and reliably. This is critical in applications where precision and consistency are paramount.

- Wide Range of Industries:

Linear bearings find application in various industries, including manufacturing, aerospace, automotive, and heavy machinery, where heavy loads need to be moved with high precision.

Overall, linear bearings serve as a cornerstone in applications that demand the simultaneous management of heavy loads and precise movement. They ensure that heavy machinery and equipment can function efficiently and accurately while maintaining the safety and integrity of the entire system.

Common Applications and Industries for Linear Bearings

Linear bearings find widespread use in a variety of applications and industries due to their ability to provide controlled linear motion. Some common applications and industries where linear bearings are essential components include:

- Industrial Automation:

Linear bearings are used in automated machinery and equipment to enable precise and repeatable movement of components. They play a critical role in assembly lines, material handling systems, and robotics.

- CNC Machinery:

In computer numerical control (CNC) machines, linear bearings facilitate accurate movement of the cutting tool or workpiece. They contribute to the precision and quality of machining operations.

- Medical Devices:

Linear bearings are crucial in medical equipment such as MRI machines, CT scanners, and robotic surgical systems. Their precision and smooth motion are vital for accurate medical procedures.

- Packaging Machinery:

In packaging and labeling machines, linear bearings ensure precise movement of containers, products, and labeling mechanisms. This results in consistent and reliable packaging processes.

- Printing Industry:

Linear bearings are used in printing presses to ensure precise movement of print heads, paper feed mechanisms, and other critical components. This helps achieve accurate printing results.

- Textile Machinery:

In textile manufacturing, linear bearings contribute to the smooth operation of spinning machines, looms, and fabric handling systems. They help maintain proper tension and alignment of materials.

- Aerospace and Defense:

Linear bearings are utilized in aerospace applications such as aircraft actuators, landing gear systems, and satellite mechanisms. They withstand harsh conditions and provide reliable motion control.

- Material Handling:

In conveyor systems and material handling equipment, linear bearings facilitate the movement of goods along production lines, warehouses, and distribution centers.

- Automotive Industry:

Linear bearings are used in automotive manufacturing for tasks like seat adjustments, sunroof operation, and door mechanisms. Their precision enhances passenger comfort.

- Scientific Research:

In laboratory equipment and scientific instruments, linear bearings contribute to accurate positioning of samples, sensors, and analytical components.

These are just a few examples of the diverse applications and industries where linear bearings are essential. Their ability to provide controlled and reliable linear motion makes them indispensable in achieving precision, efficiency, and performance across various sectors.

editor by CX 2024-05-08

China Professional Linear Motion Ball Bearing Professional Manufacturer of Linear Bearing SBR20uu carrier bearing

Product Description

Product Description

|

Product Name |

CNC aluminum linear CZPT rail SBR12 and linear slide block SBR12UU SBR12LUU |

|||

|

Material |

Aluminum |

|||

|

Color |

White |

|||

|

Grade |

C,H,P |

|||

|

Feature |

100% Interchangeable |

|||

|

Types of block |

Square/Lengthen(UU/LUU) |

|||

|

Length of linear CZPT rail |

100mm-4000mm,any length will be available |

|||

|

Application |

precision part, cnc machining parts, auto parts, industrial parts, etc |

|||

Detailed Photos

Product Parameters

Packaging & Shipping

Company Profile

ZheJiang Sair Mechanical Xihu (West Lake) Dis. Co., Ltd

ZheJiang Sair Mechanical Xihu (West Lake) Dis. Co., Ltd is 1 of the biggest linear CZPT and ball screw manufacture in China,with strong technical strength, advanced production equipments, high-quality staff team and perfect after-sales services, our company is the precision machinery manufacturer with research and development, manufacturing, sales, service all in one.

After Sales Service

Customer Service

The products are mature with high quality. They are not only sold well all over the country, but also exported to Europe, Americas, Southeast Asia, Africa and more than 70 countries. They have excellent marketing performance, highly appreciated and trusted by the vast number of customers.

If you have any needs, Please contact with me directly!

FAQ

1. Q: How about the quality of your product?

A: 100% inspection during production. Our products are certified to ISO9001-2008 international quality standards.

2. Q: What’s the delivery time?

A: For custom order, within 2000 meters, Production time is 15days after confirmed every details.

3. Q: What’s your packing?

A: Our Normal packing is bulking in PE bag, and then into plywood Cartons. We also can pack products according to your requirement.

4. Q: What about the warranty?

A: We are very confident in our products,and we pack them very well to make sure the goods in well protection.

5. Q: Could you send me your catalogue and price list?

A: As we have more than hundreds of products,it is really too hard to send all of catalogue and price list for you. Please inform us the style you interested, we can offer the pricelist for your reference.

6. Q:There are a lot of companies which export bearings, why do you choose us?

A: As we are a genuine linear CZPT supplier since 2011.and we are really factory, you need not pay the profit for middlemen. so we can offer you the lowest and competitive price .

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | CNC Machine |

|---|---|

| Material: | Steel |

| Structure: | Rail & Slider |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Differences between Open-Type and Closed-Type Linear Bearings

Open-type and closed-type linear bearings are two common variations used in linear motion systems, each with its own advantages and considerations:

- 1. Open-Type Linear Bearings:

Open-type linear bearings, as the name suggests, have an open design that allows easy access to the bearing’s rolling elements and raceways. These bearings are characterized by:

- Quick Maintenance: Open-type bearings are easier to clean, lubricate, and inspect due to their open structure, making maintenance more convenient.

- Increased Contamination Risk: Because they are exposed, open-type bearings are more susceptible to dust, debris, and contamination, which can affect their performance and lifespan.

- 2. Closed-Type Linear Bearings:

Closed-type linear bearings are enclosed within a housing or carriage that provides protection from external elements. These bearings offer the following features:

- Enhanced Contamination Protection: Closed-type bearings are less vulnerable to contaminants and offer improved protection against dust, dirt, and debris, leading to longer service life.

- Reduced Accessibility: Maintenance and inspection of closed-type bearings might be more complex due to the need to disassemble the housing or carriage for access.

- Reduced Noise: The enclosed design of closed-type bearings can contribute to reduced noise levels, which is advantageous in noise-sensitive applications.

Choosing between open-type and closed-type linear bearings depends on the specific requirements of the application. If easy maintenance and accessibility are crucial, open-type bearings might be preferred. On the other hand, closed-type bearings offer better protection against contaminants and reduced noise, making them suitable for environments where cleanliness and quiet operation are essential.

Role of Linear Bearings in Heavy Load and High Precision Applications

Linear bearings are essential components in applications that require the combined capabilities of handling heavy loads and maintaining high precision. They serve a critical role in such scenarios:

- Heavy Load Handling:

Linear bearings are designed to support and guide heavy loads along a linear path. They distribute the weight evenly, reducing friction and wear on the moving components and ensuring smooth and stable movement.

- Precision Motion Control:

Linear bearings enable precise and accurate control over the motion of heavy loads. This precision is crucial in applications where components need to be positioned or moved with extremely fine tolerances.

- Reduced Friction:

Linear bearings are engineered to minimize friction between moving parts, even under heavy load conditions. This not only improves efficiency but also enhances the accuracy of movement.

- Smooth Movement:

Linear bearings provide smooth and consistent movement, ensuring that heavy loads can be guided and positioned without jarring or sudden stops. This is particularly important for applications requiring controlled and gentle motion.

- Reduced Wear and Maintenance:

By reducing friction and wear, linear bearings extend the operational lifespan of heavy-load equipment. This translates to lower maintenance requirements and longer intervals between servicing.

- Optimized Performance:

Linear bearings contribute to the overall performance of heavy-load systems by allowing them to operate smoothly, accurately, and reliably. This is critical in applications where precision and consistency are paramount.

- Wide Range of Industries:

Linear bearings find application in various industries, including manufacturing, aerospace, automotive, and heavy machinery, where heavy loads need to be moved with high precision.

Overall, linear bearings serve as a cornerstone in applications that demand the simultaneous management of heavy loads and precise movement. They ensure that heavy machinery and equipment can function efficiently and accurately while maintaining the safety and integrity of the entire system.

Linear Bearings: Definition and Applications

Linear bearings are mechanical components designed to facilitate smooth and controlled linear motion in a single direction. They are widely used across various industries to provide precise movement and guidance in applications where traditional rotary bearings are not suitable. Linear bearings offer several advantages and find use in a diverse range of applications:

- Precision Machinery:

Linear bearings are a fundamental part of precision machinery such as CNC machines, laser cutting equipment, and coordinate measuring machines. They ensure accurate movement and positioning of tools and components, enabling high-quality and intricate work.

- Industrial Automation:

In automated manufacturing and assembly lines, linear bearings play a critical role in moving robotic arms, conveyors, and various stages along predefined paths. Their ability to provide smooth and repeatable motion contributes to increased production efficiency.

- Medical Devices:

Linear bearings are essential in medical devices like diagnostic machines, imaging systems, and robotic surgical equipment. They enable precise movement and positioning required for accurate diagnoses and minimally invasive procedures.

- Packaging Machinery:

In packaging industries, linear bearings guide the motion of conveyor belts, sealing mechanisms, and labeling devices. These bearings ensure consistent and reliable packaging processes.

- Material Handling:

Linear bearings are used in various material handling equipment such as pick-and-place systems, automated warehouses, and sorting machines. They enable efficient movement of goods and materials with reduced friction and wear.

- Semiconductor Manufacturing:

In semiconductor fabrication, where extreme precision is crucial, linear bearings are employed in wafer handling, chip assembly, and inspection equipment. They ensure contamination-free motion and positioning of delicate components.

- Textile Machinery:

Textile machines use linear bearings for guiding yarn paths, thread tensioning, and controlling the movement of fabric during weaving and knitting. These bearings contribute to the quality and efficiency of textile production.

- Automotive Manufacturing:

Linear bearings are found in automotive assembly lines for tasks such as welding, painting, and component installation. They provide accurate movement and positioning of vehicle parts, contributing to the production process.

- Aerospace and Defense:

In aerospace applications, linear bearings are used in various mechanisms, including aircraft seats, control surfaces, and satellite deployment systems. Their reliability and precision are crucial in these demanding environments.

- Renewable Energy:

In wind turbines and solar panel manufacturing, linear bearings are used to adjust the positioning of blades, solar panels, and tracking systems. They contribute to the efficiency of renewable energy generation.

Overall, linear bearings offer precise, controlled, and smooth linear motion in diverse applications across industries. Their ability to guide and support loads while minimizing friction and wear makes them essential components for achieving accurate movement and improved operational efficiency.

editor by CX 2024-04-25

China supplier Cheap Price Chinese Wholesale Popular Shaft Support Linear Motion Bearing double row ball bearing

Product Description

Linear motion bearings with Chrome plated hardness linear shafts

Company Profile

HangZhou Wangong Precision Machinery Co., Ltd.

About US: Professional producing Ball screw, Linear guide, linear shaft, Linear roller CZPT and linear motion bearings

HangZhou Wangong Precision Machinery Co., Ltd was founded in 2008 and is located in HangZhou City, ZHangZhoug Pro. China. We ahve built a R&D and profuction base of more than 52000m2 , Our expertise lies in manufacturing precision transmission components, As a distinguished high-tech enterprise, we seamlessly integrate research and development, production, sales, and service. We have successfully incorporated advanced equipment and cutting-edge technologies from renowned countries like Germany, Japan and ZheJiang .

Product Description

1,Product General information

a, Low frictional linear motion

Steel balls are accurately guided by a retainer, so low frictional resistance and stable linear motion can be achieved.

Simple replacement of conventional plain bushings

It is easy to use Linear Bushings instead of conventional plain bushings, because both types are used with a round shaft, and no major redesign is necessary.

b, Wide variations

For each dimensional series, standard, adjustable clearance and open types are available with and without seals, so the best linear bushing for the application may be selected. In addition to the standard type, the high-rigidity long type is available. These types can be selected to suit the requirements in applications.

c, Miniature linear bushing LM Compact design

Miniature Linear Bushing is very small in size, allowing for compact assembly in machines and equipment.

d,High Reliability

ERSK linear bearing has very stringent quality control standards covering every production process. With proper lubrication and use,trouble-free operation for an extended period of time is possible.

e,Smooth Operation

The high efficiency of linear shaft is vastly superior to conventional shaft. The torque required is less than 30%. Linear motion can be easily changed from rotary motion. The linear bearings are moved very smoothly in the linear shaft.

f,High Durability

Rigidly selected materials, intensive heat treating and processing techniques, backed by years of experience,have resulted in the most durable linear bearings manufactured.

g,Easy interchangable

h,Easy maintenance

the linear rails can replace the base surface installation, the old wear parts (rails and blocks) can be replaced, reduce costs.

i,Easy installation

the linear rails and carriages can be changed easily, reduce material costs, reduce product prices, reduce product replacement costs and time.

2,All kinds of linear motion bearing series

| SC-V series | SC8V, SC10V, SC12V, SC13V, SC16V, SC20V, SC25V, SC30V, SC35V, SC40V, SC50V, SC60V |

| SC-UU/SC-AJ series | SC6, SC8, SC10, SC12, SC13, SC16, SC20, SC25, SC30, SC35, SC40, SC50, SC60 |

| SC-L /SC-LAJ series | SC8L,SC10L, SC12L, SC13L, SC16L, SC20L, SC25L, SC30L, SC35L, SC40L, SC50L, SC60L |

| SCE-V series | SCE8V, SCE12V, SCE16V, SCE20V, SCE25V, SCE30V, SCE40V, SCE50V |

| SCE-UU/SCE-AJ series | SCE8, SCE10, SCE12, SCE16, SCE20, SCE25, SCE30, SCE40, SCE50, SCE60 |

| SCE-L/SCE-LAJ series | SCE8L, SCE10L, SCE12L, SCE16L, SCE20L, SCE25L, SCE30L, SCE40L, SCE50L |

| SC-V/SCE-V | SC-UU/SCE-UU | SC-AJ/SCE-AJ |

| SK | SC-L/SCE-L | SC-LAJ/SCE-LAJ |

| SHF | linear motion support | linear bearing support |

3,Specifications:

|

SPECIFICATIONS for linear blocks |

|||

|

Items |

Material |

Surface Treatment |

|

|

Linear bearing SC, SC-AJ, SC-L, SC-AJ-L |

Aluminium alloy |

Clear Anodized |

|

|

Linear bearing SCE, SCE-AJ, SCE-L, SCE-AJ-L |

Aluminium alloy |

Clear Anodized |

|

|

Linear shaft support SHF |

Aluminium alloy |

Clear Anodized |

|

|

Linear shaft support SK |

Aluminium alloy |

Clear Anodized |

|

|

Linear shaft dia4 to dia120 |

S45C or GCr15 |

Induction heating and chrome plated |

|

|

Linear bushing LM,LM-AJ, LM-L, LM-AJ-L |

GCr15 |

Induction heating or electroless nickel plating |

|

|

Linear bushing LME, LME-AJ, LME-L, LME-AJ-L

|

GCr15 |

Induction heating or electroless nickel plating |

|

Detailed Photos

4,Detailed Images: High Precision Linear Bearing Linear Block

Machine Parts

Name: linear shaft

Brand: ERSK

Original: China

the linear shaft length can be customized according to your requirements. if the shaft need be done the machinized, please send the drawings, we are CZPT to do them

Machine Parts

Name: Linear block

Brand: ERSK

Original: China

aluminium alloy case,

good surface and high precision

moving smoothly

high interchangable

Main Features

Name: SK series

Brand: ERSK

Original: China

SK series linear shaft support,

high interchangable

mounted easily

good surface and high precision

Main Features

Name: linear ball bearing

Brand: ERSK

Original: China

GCr15 balls in the linear bearing

moving smoothly

high interchangable

Linear guide block is divied to flange type and slim type without flange.or Seal type block,

Standard type block, Double bearing type block, Short type block. Also, linear block is divided to high load capacity with standard block lenth and ultra high load capacity with longer block length.

Specification:

1,In stock

2,Performance: antifriction, interchangeable

3,Material:Aluminium allooy

4,Application: CNC or automatic machinery

5, Match: could match with linear guide or linear shaft in one machinery

5 Production Process:

Related products

ERSK manufacturer main products

Our Advantages

As a distinguished high-tech enterprise, we seamlessly integrate research and development, production, sales, and service. We have successfully incorporated advanced equipment and cutting-edge technologies from renowned countries like Germany, Japan, and ZheJiang . Our commitment to innovation has led to the acquisition of multiple product design patents, and we proudly adhere to ISO9001 certification standards.

Our service

Our Team:

Professional technicians, high-quality production workers, 24-hour salespersons

OUR PHILOSOPHY:

Integrity is at the core of our values, and providing excellent

service is our top priority. We begin by understanding your

needs and strive to ensure your utmost satisfaction, forging a mutually beneficial relationship.

OUR MISSION:

Through technology and innovation, we strive to enhance

product quality and deliver exceptional products and services

to you.

OUR VISION:

We are firmly dedicated to CZPT the CZPT of highquality standards and venturing into the realm of world-class

advanced manufacturing industries.

We are excited about the opportunity to work with you and

exceed your expectations.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Warehouse Crane, Shipboard Crane, Goods Yard Crane, Building Crane, Workshop Crane |

|---|---|

| Material: | Aluminium |

| Structure: | Linear Guide |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Signs of Wear or Damage in Linear Bearings and Maintenance

Identifying signs of wear or damage in linear bearings is essential for maintaining their performance and preventing costly failures. Here are common signs of wear and damage and how to address them:

- 1. Increased Friction:

If you notice increased resistance during linear motion, it could indicate that the bearing components are wearing out. This can lead to reduced efficiency and accuracy.

- Solution: Regular Lubrication:

Ensure proper lubrication of the bearings to minimize friction and prevent premature wear. Follow manufacturer recommendations for lubrication intervals and types.

- 2. Uneven Movement:

If the linear motion becomes uneven, jerky, or experiences sudden stops, it may be due to damaged bearing components.

- Solution: Inspection and Replacement:

Inspect the bearings and associated components for any signs of damage, such as dents or cracks. Replace any damaged parts to restore smooth motion.

- 3. Abnormal Noise:

Unusual noises during linear motion, such as grinding or clicking sounds, can indicate friction and wear within the bearings.

- Solution: Lubrication and Inspection:

Lubricate the bearings as recommended and inspect for any foreign particles or debris that might be causing the noise. Clean and replace components if necessary.

- 4. Increased Play or Clearance:

If there is noticeable play or excessive clearance in the linear system, it can affect precision and lead to inaccuracies.

- Solution: Adjustment or Replacement:

Check for loose bolts, misalignment, or worn components causing the play. Make necessary adjustments or replace worn parts to restore proper fit and function.

- 5. Reduced Performance:

If your linear system is no longer achieving the desired accuracy or performance, it could be due to worn bearings.

- Solution: Maintenance and Replacement:

Regularly perform maintenance tasks, such as cleaning, lubrication, and inspection. If performance does not improve, consider replacing the bearings with new ones.

- 6. Visible Damage:

Any visible signs of physical damage, such as deformation, corrosion, or cracks, require immediate attention.

- Solution: Replacement:

If the damage is severe, replace the damaged bearings promptly to avoid further issues.

Regular maintenance practices, including proper lubrication, cleaning, and inspection, are crucial for preventing wear and damage in linear bearings. Addressing any signs of wear early can extend the lifespan of the bearings and ensure consistent performance in various applications.

Role of Linear Bearings in Heavy Load and High Precision Applications

Linear bearings are essential components in applications that require the combined capabilities of handling heavy loads and maintaining high precision. They serve a critical role in such scenarios:

- Heavy Load Handling:

Linear bearings are designed to support and guide heavy loads along a linear path. They distribute the weight evenly, reducing friction and wear on the moving components and ensuring smooth and stable movement.

- Precision Motion Control:

Linear bearings enable precise and accurate control over the motion of heavy loads. This precision is crucial in applications where components need to be positioned or moved with extremely fine tolerances.

- Reduced Friction:

Linear bearings are engineered to minimize friction between moving parts, even under heavy load conditions. This not only improves efficiency but also enhances the accuracy of movement.

- Smooth Movement:

Linear bearings provide smooth and consistent movement, ensuring that heavy loads can be guided and positioned without jarring or sudden stops. This is particularly important for applications requiring controlled and gentle motion.

- Reduced Wear and Maintenance:

By reducing friction and wear, linear bearings extend the operational lifespan of heavy-load equipment. This translates to lower maintenance requirements and longer intervals between servicing.

- Optimized Performance:

Linear bearings contribute to the overall performance of heavy-load systems by allowing them to operate smoothly, accurately, and reliably. This is critical in applications where precision and consistency are paramount.

- Wide Range of Industries:

Linear bearings find application in various industries, including manufacturing, aerospace, automotive, and heavy machinery, where heavy loads need to be moved with high precision.

Overall, linear bearings serve as a cornerstone in applications that demand the simultaneous management of heavy loads and precise movement. They ensure that heavy machinery and equipment can function efficiently and accurately while maintaining the safety and integrity of the entire system.

Factors to Consider When Selecting a Linear Bearing

Choosing the right linear bearing for a specific application involves considering several critical factors to ensure optimal performance and longevity:

- Load Requirements:

Determine the magnitude and direction of the loads the linear bearing will experience. Consider both static and dynamic loads to select a bearing with an appropriate load capacity.

- Precision and Accuracy:

For applications requiring precise positioning, choose linear bearings with high precision and low backlash. Factors like repeatability and positional accuracy are crucial.

- Speed and Acceleration:

Consider the speed and acceleration at which the linear bearing will operate. Higher speeds may require bearings with lower friction and better heat dissipation.

- Environmental Conditions:

Assess the environmental factors such as temperature, humidity, and exposure to contaminants. Choose linear bearings with suitable materials and seals to withstand the conditions.

- Space Constraints:

Take into account the available space for mounting the linear bearing. Some applications may have limited space, necessitating compact and lightweight bearing options.

- Maintenance Requirements:

Consider the maintenance needs of the bearing. Bearings with self-lubricating properties or easy access for lubrication can reduce maintenance frequency.

- Mounting and Configuration:

Choose a linear bearing that can be easily mounted and integrated into your system’s design. Consider factors like mounting orientation and available mounting surfaces.

- Life Expectancy:

Estimate the expected lifespan of the linear bearing based on the application’s requirements. Select a bearing with a suitable design life to prevent premature failures.

- Cost and Budget:

Balance the desired performance with the available budget. Opt for linear bearings that provide the necessary features without exceeding cost limitations.

- Accessories and Add-ons:

Consider any additional accessories or add-ons, such as seals, lubrication systems, or end caps, that can enhance the bearing’s performance and protection.

- Manufacturer and Supplier:

Choose reputable manufacturers and suppliers that offer reliable products and good customer support. Quality assurance and technical assistance are essential.

Overall, a comprehensive assessment of these factors will help you select the most suitable linear bearing for your specific application, ensuring optimal performance, longevity, and cost-effectiveness.

editor by CX 2024-04-12

China Custom Linear Motion Unit Shf8 Flange Mount Shaft Rod Ball Slide Bearing drive shaft bearing

Product Description

Linear Ball Bearing Slide Unit is a case unit with the standard linear bearing installed in a small and light aluminum case.The slide unit series is a line of standardized slide bearing housings and shaft supporters to enable smooth linear motion using slide bearings and shafts.

| Aluminium Linear Ball Bearing Slide Unit | |

| Model number | Supported Liner Rail: SBR16,20,25,30,35,40,50; TBR16,20,25,30 Length:0-6000mm SBR..UU: SBR10UU, SBR12UU, SBR16UU, SBR20UU, SBR25UU, SBR30UU, SBR35UU,SBR40UU, SBR50UU; SBR…LUU:SBR10LUU,SBR12LUU,SBR16LUU,SBR20LUU,SBR25LUU,SBR30LUU,SBR35LUU,SBR40LUU,SBR50LUU TBR..UU: TBR16UU, TBR20UU, TBR25UU, TBR30UU;TBR…LUU:TBR16LUU, TBR20LUU, TBR25LUU, TBR30LUU SCS..UU:SCS6UU,SCS8UU,SCS10UU,SCS12UU,SCS13UU,SCS16UU,SCS20UU,SCS25UU,SCS30UU,SCS35UU,SCS40UU,SCS50UU SCS..LUU:SCS8LUU,SCS10LUU,SCS12LUU,SCS13LUU,SCS16LUU,SCS20LUU,SCS25LUU,SCS30LUU,SCS35LUU,SCS40LUU,SCS50LUU SC..VUU: SC8VUU,SC10VUU,SC12VUU,SC13VUU,SC16VUU,SC20VUU,SC25VUU,SC30VUU,SC35VUU,SC40VUU, SC50VUU SHF..A:SHF8,SHF10,SHF12,SHF13,SHF16,SHF20,SHF25,SHF30,SHF35,SHF40,SHF50 SH..A(SK):SK8,SK10,SK12,SK13,SK16,SK20,SK25,SK30,SK35,SK40,SK50,SK60 |

| Material | Aluminum Alloy |

| Appearance | Anodized surface, high hardness, corrosion resistance, not rust, low noise |

| Application | 3D printer, milling machine, CNC engine lathe, gear shaper, hobbing, precision machine tools, robotics, semiconductor, electric tools, sports equipment, woodworking machinery, food machinery, medical machinery, textile machinery, optical instruments, glass manufacturing, automobile manufacturing equipment, automation equipment, laser engraving, blanket machinery, ceramic tile machinery, printing machinery, electronic industry, man-made board bearing equipment, machinery, paper machinery, plastic machinery, inspection devices, transmission equipment, packaging machinery, textile machinery |

| OEM&Customized | Accepted to drawing |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Warehouse Crane, Shipboard Crane, Goods Yard Crane, Building Crane, Workshop Crane |

|---|---|

| Material: | Aluminium |

| Structure: | Container Crane |

| Installation: | Roughterrain Wheeled Crane |

| Driven Type: | Hydraulic |

| Carrying Capacity: | Special Weight Level |

| Customization: |

Available

| Customized Request |

|---|

Signs of Wear or Damage in Linear Bearings and Maintenance

Identifying signs of wear or damage in linear bearings is essential for maintaining their performance and preventing costly failures. Here are common signs of wear and damage and how to address them:

- 1. Increased Friction:

If you notice increased resistance during linear motion, it could indicate that the bearing components are wearing out. This can lead to reduced efficiency and accuracy.

- Solution: Regular Lubrication:

Ensure proper lubrication of the bearings to minimize friction and prevent premature wear. Follow manufacturer recommendations for lubrication intervals and types.

- 2. Uneven Movement:

If the linear motion becomes uneven, jerky, or experiences sudden stops, it may be due to damaged bearing components.

- Solution: Inspection and Replacement:

Inspect the bearings and associated components for any signs of damage, such as dents or cracks. Replace any damaged parts to restore smooth motion.

- 3. Abnormal Noise:

Unusual noises during linear motion, such as grinding or clicking sounds, can indicate friction and wear within the bearings.

- Solution: Lubrication and Inspection:

Lubricate the bearings as recommended and inspect for any foreign particles or debris that might be causing the noise. Clean and replace components if necessary.

- 4. Increased Play or Clearance:

If there is noticeable play or excessive clearance in the linear system, it can affect precision and lead to inaccuracies.

- Solution: Adjustment or Replacement:

Check for loose bolts, misalignment, or worn components causing the play. Make necessary adjustments or replace worn parts to restore proper fit and function.

- 5. Reduced Performance:

If your linear system is no longer achieving the desired accuracy or performance, it could be due to worn bearings.

- Solution: Maintenance and Replacement:

Regularly perform maintenance tasks, such as cleaning, lubrication, and inspection. If performance does not improve, consider replacing the bearings with new ones.

- 6. Visible Damage:

Any visible signs of physical damage, such as deformation, corrosion, or cracks, require immediate attention.

- Solution: Replacement:

If the damage is severe, replace the damaged bearings promptly to avoid further issues.

Regular maintenance practices, including proper lubrication, cleaning, and inspection, are crucial for preventing wear and damage in linear bearings. Addressing any signs of wear early can extend the lifespan of the bearings and ensure consistent performance in various applications.

Role of Linear Bearings in Heavy Load and High Precision Applications

Linear bearings are essential components in applications that require the combined capabilities of handling heavy loads and maintaining high precision. They serve a critical role in such scenarios:

- Heavy Load Handling:

Linear bearings are designed to support and guide heavy loads along a linear path. They distribute the weight evenly, reducing friction and wear on the moving components and ensuring smooth and stable movement.

- Precision Motion Control:

Linear bearings enable precise and accurate control over the motion of heavy loads. This precision is crucial in applications where components need to be positioned or moved with extremely fine tolerances.

- Reduced Friction:

Linear bearings are engineered to minimize friction between moving parts, even under heavy load conditions. This not only improves efficiency but also enhances the accuracy of movement.

- Smooth Movement:

Linear bearings provide smooth and consistent movement, ensuring that heavy loads can be guided and positioned without jarring or sudden stops. This is particularly important for applications requiring controlled and gentle motion.

- Reduced Wear and Maintenance:

By reducing friction and wear, linear bearings extend the operational lifespan of heavy-load equipment. This translates to lower maintenance requirements and longer intervals between servicing.

- Optimized Performance:

Linear bearings contribute to the overall performance of heavy-load systems by allowing them to operate smoothly, accurately, and reliably. This is critical in applications where precision and consistency are paramount.

- Wide Range of Industries:

Linear bearings find application in various industries, including manufacturing, aerospace, automotive, and heavy machinery, where heavy loads need to be moved with high precision.

Overall, linear bearings serve as a cornerstone in applications that demand the simultaneous management of heavy loads and precise movement. They ensure that heavy machinery and equipment can function efficiently and accurately while maintaining the safety and integrity of the entire system.

Common Applications and Industries for Linear Bearings

Linear bearings find widespread use in a variety of applications and industries due to their ability to provide controlled linear motion. Some common applications and industries where linear bearings are essential components include:

- Industrial Automation:

Linear bearings are used in automated machinery and equipment to enable precise and repeatable movement of components. They play a critical role in assembly lines, material handling systems, and robotics.

- CNC Machinery:

In computer numerical control (CNC) machines, linear bearings facilitate accurate movement of the cutting tool or workpiece. They contribute to the precision and quality of machining operations.

- Medical Devices:

Linear bearings are crucial in medical equipment such as MRI machines, CT scanners, and robotic surgical systems. Their precision and smooth motion are vital for accurate medical procedures.

- Packaging Machinery:

In packaging and labeling machines, linear bearings ensure precise movement of containers, products, and labeling mechanisms. This results in consistent and reliable packaging processes.

- Printing Industry:

Linear bearings are used in printing presses to ensure precise movement of print heads, paper feed mechanisms, and other critical components. This helps achieve accurate printing results.

- Textile Machinery:

In textile manufacturing, linear bearings contribute to the smooth operation of spinning machines, looms, and fabric handling systems. They help maintain proper tension and alignment of materials.

- Aerospace and Defense:

Linear bearings are utilized in aerospace applications such as aircraft actuators, landing gear systems, and satellite mechanisms. They withstand harsh conditions and provide reliable motion control.

- Material Handling:

In conveyor systems and material handling equipment, linear bearings facilitate the movement of goods along production lines, warehouses, and distribution centers.

- Automotive Industry:

Linear bearings are used in automotive manufacturing for tasks like seat adjustments, sunroof operation, and door mechanisms. Their precision enhances passenger comfort.

- Scientific Research:

In laboratory equipment and scientific instruments, linear bearings contribute to accurate positioning of samples, sensors, and analytical components.

These are just a few examples of the diverse applications and industries where linear bearings are essential. Their ability to provide controlled and reliable linear motion makes them indispensable in achieving precision, efficiency, and performance across various sectors.

editor by CX 2024-04-09

China Hot selling High Precision Linear Motion Ball Sliding Bearing Lmh20uu carrier bearing

Product Description

Essential details:

Type: LINEAR.

Material: Bearing steel/Chrome steel,Gcr15.

Model Number:LMH8.

Project: Flanged linear ball bearing.

Stock: Rich.

Lubrication:Grease & Oil.

Service:OEM & ODM.

Precision Rating:P0 P6 P5 p4 p2.

Feature:Long Life.

Package:package+carton+pallet.

Applicable Industries:Advertising Company, Building Material Shops, Construction works…….

Applications

Linear Bearing:

Linear bearing is a linear motion system, used for linear travel and cylindrical axis.Due to coat point contact ball bearing with bearing, steel ball roll with minimum friction resistance, so the linear bearing small friction, and relatively stable, not over bearing speed changes, and can obtain high sensitivity, high precision of stationary linear motion.

The consumption of linear bearing also has its limitation. The most important 1 is that the bearing has poor impact load capacity and poor bearing capacity.Linear bearing quick and easy to optimize automatic selection included.

Features

Straight line bearing is used in conjunction with quenching straight line drive shaft.A system that moves in an infinite straight line.The load ball bearing and quenching transmission shaft are point contact, so the allowable load is small, but when moving in a straight line, the friction resistance is minimal, the precision is high, and the motion is fast.

Linear Motion Bearings Main Products:

Linear motion ball bearing ,Flanged linear motion ball bearing ,Linear motion ball bearing slide units,Support rail units,Shaft sport,Shafts ,etc. The main type as belows :

Product Parameters

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | High Precision/Rigidity |

|---|---|

| Function: | Super |

| Flange Shape: | Cutting-Edge |

| Samples: |

US$ 3.6/Piece

1 Piece(Min.Order) | Order Sample linear bearing

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Differences between Open-Type and Closed-Type Linear Bearings

Open-type and closed-type linear bearings are two common variations used in linear motion systems, each with its own advantages and considerations:

- 1. Open-Type Linear Bearings:

Open-type linear bearings, as the name suggests, have an open design that allows easy access to the bearing’s rolling elements and raceways. These bearings are characterized by:

- Quick Maintenance: Open-type bearings are easier to clean, lubricate, and inspect due to their open structure, making maintenance more convenient.

- Increased Contamination Risk: Because they are exposed, open-type bearings are more susceptible to dust, debris, and contamination, which can affect their performance and lifespan.

- 2. Closed-Type Linear Bearings:

Closed-type linear bearings are enclosed within a housing or carriage that provides protection from external elements. These bearings offer the following features:

- Enhanced Contamination Protection: Closed-type bearings are less vulnerable to contaminants and offer improved protection against dust, dirt, and debris, leading to longer service life.

- Reduced Accessibility: Maintenance and inspection of closed-type bearings might be more complex due to the need to disassemble the housing or carriage for access.

- Reduced Noise: The enclosed design of closed-type bearings can contribute to reduced noise levels, which is advantageous in noise-sensitive applications.

Choosing between open-type and closed-type linear bearings depends on the specific requirements of the application. If easy maintenance and accessibility are crucial, open-type bearings might be preferred. On the other hand, closed-type bearings offer better protection against contaminants and reduced noise, making them suitable for environments where cleanliness and quiet operation are essential.

Enhancing 3D Printers and Additive Manufacturing with Linear Bearings

Linear bearings play a crucial role in the efficient and precise operation of 3D printers and additive manufacturing processes. Here’s how they contribute to these technologies:

- Precise Motion Control:

Linear bearings provide smooth and accurate linear motion control, ensuring precise positioning of the print head or build platform. This precision is essential for creating intricate and detailed 3D printed objects.

- High Repeatability:

Linear bearings offer high repeatability, enabling the printer to consistently recreate complex geometries layer by layer. This is crucial for producing parts with consistent quality and dimensions.

- Reduced Vibration and Wobble:

The smooth motion provided by linear bearings minimizes vibrations and wobbling during printing, leading to smoother surface finishes and improved print quality.

- High-Speed Printing:

Linear bearings can handle high speeds, allowing 3D printers to operate at faster print speeds without sacrificing accuracy. This is beneficial for reducing overall print time.

- Compact Design:

Many linear bearings have a compact and space-efficient design, which is important for fitting within the confined spaces of 3D printers while maintaining the required range of motion.

- Low Friction and Wear:

Linear bearings are designed to minimize friction and wear, leading to longer lifespan and reduced maintenance requirements. This is especially important in additive manufacturing where continuous operation is desired.

- Smooth Layer-by-Layer Building:

In additive manufacturing, linear bearings enable precise movement of the build platform or print head, ensuring that each layer is accurately aligned and built upon the previous layer.

- Complex Geometries:

Linear bearings enable 3D printers to create complex and intricate geometries that require precise control over the movement of the print head and build platform.

Overall, linear bearings contribute to the success of 3D printing and additive manufacturing by providing the necessary motion control, precision, and reliability needed to create high-quality and intricate 3D printed objects.

Advantages of Linear Bearings over Other Bearing Types

Linear bearings offer several distinct advantages when compared to other types of bearings, particularly in applications that require controlled linear motion. These benefits contribute to their widespread use across various industries:

- Precise Linear Motion:

Linear bearings are designed specifically for linear motion, providing accurate and controlled movement along a defined path. This precision is essential in applications that demand accurate positioning and repeatability.

- Low Friction:

Linear bearings are designed to minimize friction during motion. The reduced friction translates to smoother movement, reduced wear, and improved efficiency, making them suitable for applications requiring consistent motion.

- High Load Capacity:

Linear bearings can handle significant loads in both radial and axial directions. This capability allows them to support heavy components and maintain stability under various loads.

- Minimal Maintenance:

Due to their design and minimal contact between moving parts, linear bearings require less maintenance compared to other types of bearings. This is particularly advantageous in hard-to-reach or inaccessible areas.

- Guided Motion:

Linear bearings provide guided and constrained motion along a single axis. This guidance eliminates the need for complex guiding mechanisms, reducing design complexity and simplifying assembly.

- Compact Design:

Linear bearings have a compact form factor, making them suitable for applications with limited space. Their small footprint allows for efficient use of available area.

- Low Noise and Vibration:

Linear bearings generate minimal noise and vibration during operation, contributing to quieter and more comfortable working environments in applications such as medical devices and precision machinery.

- Smooth Movement:

Linear bearings offer smooth and consistent movement, essential for applications requiring continuous and controlled motion, such as robotic systems and conveyor belts.

- Customization:

Linear bearings can be designed to fit specific application requirements, including load capacity, travel distance, and environmental conditions. This customization enhances their suitability for diverse applications.

- Reduced Wear:

The low friction and guided motion of linear bearings result in reduced wear on both the bearing and the mating surface, leading to longer service life and reduced maintenance costs.

Overall, the benefits of using linear bearings make them a preferred choice in applications that demand accurate linear motion, efficient load handling, and reduced maintenance. Their ability to deliver precision, stability, and reliability contributes to improved performance across various industries.

editor by CX 2024-04-03

China Professional Double -Wide Type Linear Motion Ball Bearing bearing distributors

Product Description

Structure and Feature

1.the linear motion bearing consists of an outer cylinder,ball retainer, balls and 2 end rings .the ball retainer which holds the balls in the recirculating trucks in held inside the outer cylinder by end rings

2.those parts are assembled to optimize their rquired functions.

3.the outer cylinder is maintained sufficient hardness by heat treatment, therefore it ensures the bushings projected travel life and satisfactory durability.

4.the ball retainer is made from steel or resin .the steel retainer has high rigidity obtained by heat treatment. the user can select the optimum type for meeting the users service conditions.

function :

1. high precision and rigidity

the linear motion bearing is produced from a solid steel outer cylinder. also the linear motion bearing incorporates either an patented all steel hardend seamless ball retainer or an industrial strength resinratainen.

2.easy of assembly

the standard type of the linear motion bearing can be loaded from any diraction .precision control is possible using only the shaft supporter,an the mounting surface can be machined easily. we also provides a variely of housings for all types of slide bushings. offering convenience of design and assembly.

3. easey of replacement

the linear motion bearing of each type are completely interchangeable because of their standardized imensions and strict precision control. replalcement because of wear of damage is therefore easy and acdurate.

4.variety of types

we offers a full line of linear motion bearing :the standard ,integral single-retainer closed type, the clearance adjustable type and the open .double -retainer ,and flanged type .the user can choose from among these according to the application requirements to be met .

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Corrosion Resistant, High Temperature, High Speed |

|---|---|

| Function: | Ordinary |

| Flange Shape: | Oval |

| Shape: | Straight |

| Series: | LME |

| Material: | Stainless Steel |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | |

|---|

Prolonging the Life of Linear Bearings Through Maintenance Practices

Implementing proper maintenance practices is essential to extend the lifespan of linear bearings and ensure their optimal performance. Here are specific maintenance practices that can help:

- 1. Regular Lubrication:

Ensure that linear bearings are properly lubricated as recommended by the manufacturer. Adequate lubrication minimizes friction, reduces wear, and prevents premature failure.

- 2. Cleaning:

Regularly clean the linear bearing components to remove dirt, debris, and contaminants. Keeping the bearings clean reduces the risk of abrasive particles causing damage.

- 3. Inspection:

Periodically inspect linear bearings for signs of wear, damage, or misalignment. Look for uneven wear patterns, visible damage, or any unusual behavior during motion.

- 4. Alignment:

Ensure proper alignment of the linear components to prevent excessive stress on the bearings. Misalignment can lead to premature wear and reduced lifespan.

- 5. Proper Handling:

Handle linear bearings with care during installation and maintenance. Avoid dropping or impacting the bearings, which can cause internal damage.

- 6. Load Distribution:

Distribute loads evenly across multiple linear bearings if applicable. This prevents overloading individual bearings and extends their life.

- 7. Environmental Considerations:

Protect linear bearings from harsh environments, extreme temperatures, and corrosive substances. Use appropriate seals and enclosures to prevent contamination.

- 8. Regular Maintenance Schedule:

Create a maintenance schedule based on usage and manufacturer recommendations. Consistent maintenance helps identify issues early and prevents unexpected failures.

- 9. Proper Storage:

Store spare linear bearings in a clean and dry environment. Avoid exposure to moisture and dust, which can damage the bearings over time.

- 10. Consult Manufacturer Guidelines:

Follow the manufacturer’s guidelines and recommendations for maintenance, lubrication, and replacement intervals specific to the linear bearings you are using.

By implementing these maintenance practices, you can significantly prolong the life of linear bearings, reduce downtime, and ensure optimal performance in various applications.

Contribution of Linear Bearings to Smooth Movement of Conveyors and Slides

Linear bearings play a crucial role in ensuring the smooth movement and operation of industrial conveyors and linear slides. Their contributions are as follows:

- Reduced Friction:

Linear bearings are designed to minimize friction between moving components, facilitating smooth motion of conveyors and linear slides. This reduces wear and tear, energy consumption, and the need for frequent maintenance.

- Precision Movement:

Linear bearings enable precise positioning and controlled movement. This precision is vital for conveyors and slides that require accurate placement of materials, products, or components.

- Stability and Load Distribution:

Linear bearings distribute loads evenly across the bearing surface, enhancing stability and preventing uneven wear. This is especially important for conveyors that handle varying loads and linear slides that support heavy components.

- Quiet and Vibration-Free Operation:

Linear bearings contribute to quiet and vibration-free operation. This is crucial in environments where noise reduction and minimal vibrations are essential for the comfort of operators and the integrity of products.

- Efficient Energy Transfer:

Linear bearings ensure efficient energy transfer by reducing energy losses due to friction. This efficiency is particularly beneficial in systems where multiple conveyors or slides are connected, improving overall system performance.

- Longevity and Reliability:

Linear bearings enhance the longevity and reliability of conveyors and slides by reducing wear on moving parts. This results in extended operational lifespans and reduced downtime for maintenance.

- Flexibility and Customization:

Linear bearings come in various designs and sizes, allowing for customization to suit specific conveyor or slide requirements. This adaptability is valuable for accommodating different loads and motion profiles.

- Wide Range of Industries:

Linear bearings find application in industries such as manufacturing, logistics, packaging, and material handling, where conveyors and linear slides are essential components of the workflow.

In summary, linear bearings contribute significantly to the efficient, precise, and reliable movement of industrial conveyors and linear slides. Their ability to reduce friction, ensure stability, and support heavy loads enhances the overall performance of these systems.

Common Applications and Industries for Linear Bearings

Linear bearings find widespread use in a variety of applications and industries due to their ability to provide controlled linear motion. Some common applications and industries where linear bearings are essential components include:

- Industrial Automation:

Linear bearings are used in automated machinery and equipment to enable precise and repeatable movement of components. They play a critical role in assembly lines, material handling systems, and robotics.

- CNC Machinery:

In computer numerical control (CNC) machines, linear bearings facilitate accurate movement of the cutting tool or workpiece. They contribute to the precision and quality of machining operations.

- Medical Devices:

Linear bearings are crucial in medical equipment such as MRI machines, CT scanners, and robotic surgical systems. Their precision and smooth motion are vital for accurate medical procedures.

- Packaging Machinery:

In packaging and labeling machines, linear bearings ensure precise movement of containers, products, and labeling mechanisms. This results in consistent and reliable packaging processes.

- Printing Industry:

Linear bearings are used in printing presses to ensure precise movement of print heads, paper feed mechanisms, and other critical components. This helps achieve accurate printing results.

- Textile Machinery:

In textile manufacturing, linear bearings contribute to the smooth operation of spinning machines, looms, and fabric handling systems. They help maintain proper tension and alignment of materials.

- Aerospace and Defense:

Linear bearings are utilized in aerospace applications such as aircraft actuators, landing gear systems, and satellite mechanisms. They withstand harsh conditions and provide reliable motion control.

- Material Handling: