Product Description

01 Product Parameter

| Tapered Roller Bearing | ||||||||||||||

| Single Row Tapered Roller Bearing | ||||||||||||||

| Bearing No. | dxDxTxBxC (mm) | Weight(kg) | Bearing No. | dxDxTxBxC (mm) | Weight(kg) | |||||||||

| 35712 | 15 | 35 | 12 | 7 | 5 | 0.050 | 30302 | 15 | 42 | 14.25 | 13 | 11 | 0.098 | |

| 35713 | 17 | 40 | 13.25 | 12 | 11 | 0.080 | 30303 | 17 | 47 | 15.25 | 14 | 12 | 0.134 | |

| 35714 | 20 | 47 | 15.25 | 14 | 12 | 0.127 | 30304 | 20 | 52 | 16.25 | 16 | 13 | 0.176 | |

| 35715 | 25 | 52 | 16.25 | 15 | 13 | 0.154 | 30305 | 25 | 62 | 18.25 | 17 | 15 | 0.272 | |

| 35716 | 30 | 62 | 17.25 | 16 | 14 | 0.241 | 30306 | 30 | 72 | 20.75 | 19 | 16 | 0.408 | |

| 35717 | 35 | 72 | 18.25 | 17 | 15 | 0.344 | 30307 | 35 | 80 | 22.75 | 21 | 18 | 0.540 | |

| 35718 | 40 | 80 | 19.75 | 18 | 16 | 0.435 | 30308 | 40 | 90 | 25.25 | 23 | 20 | 0.769 | |

| 35719 | 45 | 85 | 20.75 | 19 | 16 | 0.495 | 30309 | 45 | 100 | 27.25 | 25 | 22 | 1.571 | |

| 35710 | 50 | 90 | 21.75 | 20 | 17 | 0.563 | 3571 | 50 | 110 | 29.25 | 27 | 23 | 1.310 | |

| 35712 | 60 | 110 | 23.75 | 22 | 19 | 0.949 | 3571 | 55 | 120 | 31.5 | 29 | 25 | 1.660 | |

| 35713 | 65 | 120 | 24.75 | 23 | 20 | 1.180 | 3571 | 65 | 140 | 36 | 33 | 28 | 2.550 | |

| 35714 | 70 | 125 | 26.25 | 24 | 21 | 1.260 | 3571 | 70 | 150 | 38 | 35 | 30 | 3.060 | |

| 35715 | 75 | 130 | 27.25 | 25 | 22 | 1.410 | 3571 | 75 | 160 | 40 | 37 | 31 | 3.570 | |

| 35716 | 80 | 140 | 28.25 | 26 | 22 | 1.720 | 3 0571 | 80 | 170 | 42.5 | 39 | 33 | 4.410 | |

| 35717 | 85 | 150 | 30.5 | 28 | 24 | 2.140 | 3 0571 | 85 | 180 | 44.5 | 41 | 34 | 5.200 | |

| 35718 | 90 | 160 | 32.5 | 30 | 26 | 2.660 | 3 0571 | 90 | 190 | 46.5 | 43 | 36 | 6.030 | |

| 35719 | 95 | 170 | 34.5 | 32 | 27 | 3.070 | 3571 | 95 | 200 | 49.5 | 45 | 38 | 6.980 | |

| 35710 | 100 | 180 | 37 | 34 | 29 | 3.780 | 30320 | 100 | 215 | 51.5 | 47 | 39 | 8.560 | |

| 32222 | 110 | 200 | 56 | 4941 | 7.180 | |||||||||

| 31305 | 25 | 62 | 18.25 | 17 | 13 | 0.284 | ||||||||

| 31306 | 30 | 72 | 20.75 | 19 | 14 | 0.398 | ||||||||

| 31307 | 35 | 80 | 22.75 | 21 | 15 | 0.530 | ||||||||

| 31308 | 40 | 90 | 25.25 | 23 | 17 | 0.738 | ||||||||

| 31311 | 55 | 120 | 31.5 | 29 | 21 | 1.590 | ||||||||

| 31313 | 65 | 140 | 36 | 33 | 23 | 2.420 | ||||||||

| 31314 | 70 | 150 | 38 | 35 | 25 | 2.920 | ||||||||

| 31315 | 75 | 160 | 40 | 37 | 26 | 3.470 | ||||||||

| 31316 | 80 | 170 | 42.5 | 39 | 27 | 4.110 | ||||||||

| 31317 | 85 | 180 | 44.5 | 41 | 28 | 4.850 | ||||||||

| 31318 | 90 | 190 | 46.5 | 43 | 30 | 5.660 | ||||||||

| 31320 | 100 | 215 | 56.5 | 51 | 35 | 8.670 | ||||||||

| 31326 | 130 | 280 | 66 | 63 | 47 | 11.390 | ||||||||

| 32203 | 17 | 40 | 17.25 | 16 | 14 | 0.102 | ||||||||

| 32204 | 20 | 47 | 19.25 | 18 | 15 | 0.160 | 32304 | 20 | 52 | 22.25 | 21 | 18 | 0.245 | |

| 32205 | 25 | 52 | 19.25 | 18 | 16 | 0.187 | 32305 | 25 | 62 | 25.25 | 24 | 20 | 0.381 | |

| 32206 | 30 | 62 | 21.25 | 20 | 17 | 0.301 | 32306 | 30 | 72 | 28.75 | 27 | 23 | 0.583 | |

| 32207 | 35 | 72 | 24.25 | 23 | 19 | 0.457 | 32307 | 35 | 80 | 32.75 | 31 | 25 | 0.787 | |

| 32208 | 40 | 80 | 24.75 | 23 | 19 | 0.558 | 32308 | 40 | 90 | 35.25 | 33 | 27 | 1.080 | |

| 32209 | 45 | 85 | 24.75 | 23 | 19 | 0.607 | 32309 | 45 | 100 | 38.25 | 36 | 30 | 1.460 | |

| 32210 | 50 | 90 | 24.75 | 23 | 19 | 0.648 | 32310 | 50 | 110 | 42.25 | 40 | 33 | 1.920 | |

| 32211 | 55 | 100 | 26.75 | 25 | 21 | 0.876 | 32311 | 55 | 120 | 45.5 | 43 | 35 | 2.440 | |

| 32212 | 60 | 110 | 29.75 | 28 | 24 | 1.180 | 32312 | 60 | 130 | 48.5 | 46 | 37 | 3.571 | |

| 32213 | 65 | 120 | 32.75 | 31 | 27 | 1.580 | 32313 | 65 | 140 | 51 | 48 | 39 | 3.660 | |

| 32214 | 70 | 125 | 33.25 | 31 | 27 | 1.680 | 32314 | 70 | 150 | 54 | 51 | 42 | 4.460 | |

| 32215 | 75 | 130 | 33.25 | 31 | 27 | 1.740 | 32315 | 75 | 160 | 58 | 55 | 45 | 5.350 | |

| 32216 | 80 | 140 | 35.25 | 33 | 28 | 2.180 | 32316 | 80 | 170 | 61.5 | 58 | 48 | 6.410 | |

| 32217 | 85 | 150 | 38.5 | 36 | 30 | 2.750 | 32317 | 85 | 180 | 63.5 | 60 | 49 | 7.150 | |

| 32218 | 90 | 160 | 42.5 | 40 | 34 | 3.490 | 32318 | 90 | 190 | 67.5 | 64 | 53 | 8.570 | |

| 32219 | 95 | 170 | 45.5 | 43 | 37 | 4.300 | 32319 | 95 | 200 | 71.5 | 67 | 55 | 10.10 | |

| 32220 | 100 | 180 | 49 | 46 | 39 | 5.120 | 32320 | 100 | 215 | 77.5 | 73 | 60 | 12.70 | |

| 32004X | 20 | 42 | 15 | 15 | 12 | 0.097 | ||||||||

| 32911 | 55 | 80 | 17 | 17 | 14 | 0.274 | 32005X | 25 | 47 | 15 | 15 | 11.5 | 0.114 | |

| 32912 | 60 | 85 | 17 | 17 | 14 | 0.296 | 32006X | 30 | 55 | 17 | 17 | 13 | 0.166 | |

| 32914 | 70 | 100 | 20 | 20 | 16 | 0.487 | 32007X | 35 | 62 | 18 | 18 | 14 | 0.224 | |

| 32915 | 75 | 105 | 20 | 20 | 16 | 0.511 | 32008X | 40 | 68 | 19 | 19 | 14.5 | 0.273 | |

| 32916 | 80 | 110 | 20 | 20 | 16 | 0.540 | 32009X | 45 | 75 | 20 | 20 | 15.5 | 0.346 | |

| 32917 | 85 | 120 | 23 | 23 | 18 | 0.773 | 32571X | 50 | 80 | 20 | 20 | 15.5 | 0.366 | |

| 32918 | 90 | 125 | 23 | 23 | 18 | 0.817 | 32011X | 55 | 90 | 23 | 23 | 17.5 | 0.563 | |

| 32919 | 95 | 130 | 23 | 23 | 18 | 0.851 | 32012X | 60 | 95 | 23 | 23 | 17.5 | 0.576 | |

| 32920 | 100 | 140 | 25 | 25 | 20 | 1.140 | 32013X | 65 | 100 | 23 | 23 | 17.5 | 0.630 | |

| 33108 | 40 | 75 | 26 | 26 | 20.5 | 0.494 | 32014X | 70 | 110 | 25 | 25 | 19 | 0.848 | |

| 33109 | 45 | 80 | 26 | 26 | 20.5 | 0.542 | 32015X | 75 | 115 | 25 | 25 | 19 | 0.909 | |

| 33110 | 50 | 85 | 26 | 26 | 20 | 0.580 | 32016X | 80 | 125 | 29 | 29 | 22 | 1.280 | |

| 33111 | 55 | 95 | 30 | 30 | 23 | 0.846 | 32017X | 85 | 130 | 29 | 29 | 22 | 1.350 | |

| 33112 | 60 | 100 | 30 | 30 | 23 | 0.912 | 32018X | 90 | 140 | 32 | 32 | 24 | 1.790 | |

02 Product Advantages

1. High stiffness

2. High radial load carrying capacity

3. Very low cross-sectional height

4. APQP: product quality advance plHangZhou

5. SPC: Statistical process control

6. MSA: Measurement system analysis

7. FMEA: Analysis of potential failure modes and consequences

8. PPAP: Production part approval procedure

03 Product Applications

***BEARING***

MORE APPLICATIONS

| Construction machinery |

| Steam trucks |

| Mines |

| Petroleum |

| Machine tools |

| Metallurgy |

| Railways |

| Electric power |

| Other industries |

04 Company Profile

Established in 2012, HangZhou Granville is a branch of the Granville Group. With our experience, competitive prices and excellent service, we have won the praise of our customers. Our business involves standard and special industrial parts, automotive parts and construction machinery parts required for a variety of different industrial applications.

Our main products include

Bearing series :ball bearings, deep groove ball bearings, self-aligning ball bearings, angularcontact ball bearings, cylindrical roller bearing, tapered roller bearings, thrust ball bearings, thrust rollerbearings, needle bearings, spherical bearings, joint bearings, pillow blocks, linear bearings, etc.

Accessories series:Automotive Spare Parts,Seals & O-rings ,Power transmission parts Chain and Sprocket

Our products are mainly exported to Europe, America, Middle East, Southeast Asia, India, Pakistan, Bangladesh, Singapore, Korea and other countries around the world. We have a large number of products in stock, which can be delivered with high efficiency in the shortest possible time to solve your matching problems in time. In addition, we have reliable quality and quantity of products to offer. We adhere to the principle of CZPT situation and insist on “providing comprehensive quality products and best reputation” to provide excellent services to our customers.

Company Events

05 Our Advantages

1. We have the most advanced bearing process equipment, CNC automatic facilities, and testing instruments.

2. We manufacture ball bearings and mounted bearing units, and also provide a strong full range of products, including electric motors and components One-stop partnerships products from our audited supply chain.

3. All products are manufactured exclusively by companies with ISO 9001:2008 certified Quality Systems which use state-of-the-art machines. The quality path starts from the beginning to deliver and goods’ quality trackable

>>>Market Distribution Map

06 Packaging & Shipping

| Packaging | shipping |

| vacuum packaging | express delivery |

| Color Box | BY SEA |

| Industrial Package | BY AIR |

| Carton | Training |

| Pallet | Trucking |

07 Quality Warranty

Granville as a manufacturer of high quality products, guarantees compliance with the highest standards relative to the use of the best steel quality in the production process, the highest standards in the design of contact surfaces, as well as the most efficient packing and lubrication of parts. From material coming, quality control through all processes. Except interal test, goods to third party inspection if required. After the center of inspection and experiment being founded, effective methods of inspecting all kinds of raw materials are mastered and then the reliability of bearings is ensured. One of our main objectives is the continued improvement in the quality of our products and processes, in pursuit of which we obtained ISO certification 9001:2008 and TS16949.

08 Advantage Manufacturing Processes and Quality Control:

01Heat Treatment

02 Centerless Grinding Machine 11200 (most advanced)

03 Automatic Production Lines for Raceway

04 Automatic Production Lines for Raceway

05 Ultrasonic Cleaning of Rings

06 Automatic Assembly

07 Ultrasonic Cleaning of Bearings

08 Automatic Greasing, Seals Pressing

09Measurement of Bearing Vibration (Acceleration)

10 Measurement of Bearing Vibration (Speed)

11 Laser Marking

12 Automatic Packing

>>> CZPT Hot Sale Recommendations(Click on the picture or link below)

Deep Groove Ball Bearing

1. 16000 series

product/lwOaVtSUAWYM/China-Gil-Best-Sales-Deep-Groove-Ball-Bearing-Wheel-Hub-Bearing-Auto-parts-16002.html

2.6200 &6400 & 6800 series

1> product/MdoTObRGfNVJ/China-OEM–Deep-Groove-Ball-Auto-Wheel-Taper-Cylindrical-Roller-Pillow-Block-Centrifugal-Pumps-Screw-Compressors-Diesel-generator-set-bearing.html

2> product/rnhUORpxTJkH/China-GIL-Best-Sales-6400-Series-Deep-Groove-Ball-Bearing-for-Auto-Parts.html

3> product/CZFGptdMkWUc/China-Gil-Best-Sales-Deep-Groove-Ball-Bearing-Wheel-Hub-Bearing-Auto-parts-6800-6801-6804-RS-ZZ.html

3.68000 series

product/MxWrkYyDgQVe/China-Gil-Best-Sales-Thin-Deep-Groove-Ball-Bearing-6800-Series-Wheel-Hub-Bearing-Auto-parts.html

Tapered Roller Bearing

1.

product/vwOTPMGdeZkF/China-32008X-32009X-32571X-32011X-32012X-Tapered-Roller-wheel-Hub-linear-guide-steel-ball-Diesel-generator-sets-auto-gear-Engine-motorcycle-tractor-ABEC-1688-bearing.html

2. product/KOdTGjaySwcA/China-32005X-32006X-32007X-32008X-32009X-32571X-Tapered-Roller-thrust-china-wholesale-Engine-motorcycle-tractor-wheel-linear-guide-Diesel-generator-sets-1688-Bearing.html

3. product/gOZAfHGjAwhT/China-32004X-Tapered-Roller-china-wholesale-Angular-Contact-Ball-Wheels-bearing-motor-Food-Machinery-auto-Industrial-Motor-Bicycle-Ball-Valves-engine-1688-Bearing.html

Angular Contact Ball bearing

1. product/HZJfkoOdkwVn/China-china-wholesale-7203-7204-7300-Angular-Contact-Ball-Wheels-motor-Food-Machinery-auto-Industrial-Motor-Bicycle-Ball-Valves-engine-Bicycle-ABEC-71812-1688-bearing.html

2. product/gZJazpNYCOkb/China-7000-Series-High-Precision-Low-Noise-Angular-Contact-Ball-Bearing-Wheels-bearing-motor-Food-Machinery-auto-Industrial-Motor-Bicycle-Ball-Valves-engine-bearings.html

Bearing Units

1. product/cEvYRDsHaxWl/China-china-wholesale-UCFL206-UCFL208-UCFL204-UCFL305-UKFL205-Pillow-Blocks-Bearing-Housing-Agricultura-Flanged-unit-auto-Industrial-Motor-Bicycle-1688-bearing-Unit.html

2. product/KxpUIJvDJQVZ/China-china-wholesale-UCP-205-Pillow-Blcoks-Bearing-House-Angular-Contact-Ball-Wheels-bearing-motor-Food-Machinery-auto-Industrial-Motor-Bicycle-1688-bearing-Units.html

3. product/XnpUsDZbCQkh/China-Manufacturer-direct-sales-UCLP-2-series-High-Precision-Pillow-Blocks-Bearing-House-Units-Agricultural-Machinery-parts.html

09 After Sales Service

- Optimize customer inventory and reduce cost

- Provide maintenance solutions

10 FAQ

Q1. Can you accept OEM and customization?

A: Yes. We can customize it according to the samples and drawings you provide.

Q2. Do you keep a stock of these things?

A: In stocks

Q3. Can you provide samples free of charge?

A: Yes. We can provide samples free of charge. But the freight is paid by the customer.

Q4. What’s the delivery date?

A:The delivery time of sample orders is 3 working days.The bulk orders are 5-10 working days.

Q5. Why your price is higher than others?

A: Price = quality . We firmly believe that by the quality of the customer is always get more reliable than on price . So we insist on doing high-quality products.

Q6. What kind of transport do you have ?

A: According to the weight,we will choose the most appropriate mode of transport for you. Our freight forwarding is efficient and cheap.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Small and Medium-Sized (60-115mm) |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | Order Sample Sample unit price depends on the specific model

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Contribution of Linear Bearings to CNC Machining Efficiency and Accuracy

Linear bearings play a crucial role in enhancing the efficiency and accuracy of Computer Numerical Control (CNC) machining processes. Here’s how they contribute:

- 1. Enhanced Precision:

Linear bearings provide smooth and precise linear motion along machine axes. This precision is essential for achieving tight tolerances and accurate dimensions in machined parts.

- 2. Reduced Friction and Wear:

Low friction in linear bearings minimizes energy loss and heat generation during movement. This reduces wear on the components and extends the lifespan of the machine, resulting in consistent performance over time.

- 3. Smooth Motion Control:

Linear bearings enable controlled and predictable motion, allowing CNC machines to execute complex tool paths with smooth transitions. This is crucial for producing intricate shapes and achieving high-quality surface finishes.

- 4. Minimized Vibration and Noise:

The smooth operation of linear bearings reduces vibration and noise levels during machining. This is especially important for maintaining a stable machining environment and producing parts with minimal surface imperfections.

- 5. Rapid Traverse Speeds:

Linear bearings facilitate rapid movements of machine components between machining operations. This increases the efficiency of the machining process, reducing cycle times and increasing overall productivity.

- 6. High Acceleration and Deceleration:

Linear bearings allow CNC machines to accelerate and decelerate rapidly without sacrificing precision. This capability is advantageous for optimizing machining time while maintaining accuracy.

- 7. Improved Repeatability:

Linear bearings ensure consistent and repeatable motion, resulting in parts that match design specifications precisely across multiple production runs.

- 8. Flexibility in Design:

Linear bearings enable the design of compact and space-efficient CNC machines. Their small footprint allows for more efficient use of manufacturing floor space.

In summary, linear bearings significantly enhance CNC machining by providing accurate, smooth, and controlled motion. This translates into higher precision, reduced wear, improved surface finishes, and increased productivity. Whether it’s milling, turning, or other CNC processes, linear bearings are essential for achieving the level of accuracy and efficiency demanded by modern manufacturing.

Recent Advancements in Linear Bearing Technology

Recent years have seen significant advancements in linear bearing technology, leading to improved performance, reliability, and versatility. Some notable developments include:

- Nanotechnology: The integration of nanotechnology has allowed for the development of ultra-precision linear bearings with nanometer-scale accuracy. These bearings are ideal for applications requiring extremely fine movement and positioning.

- Smart Bearings: Advances in sensor technology have enabled the creation of smart linear bearings that can monitor parameters like temperature, load, and vibration in real time. This data helps in predictive maintenance and optimizing operational efficiency.

- Materials Innovation: New materials with enhanced properties, such as self-lubricating and corrosion-resistant coatings, have extended the lifespan of linear bearings and reduced the need for frequent lubrication and maintenance.

- Compact Designs: Manufacturers are designing more compact linear bearings to suit space-constrained applications while maintaining high load capacity and precision.

- Environmental Sustainability: There’s a growing emphasis on developing linear bearings with reduced environmental impact, including using eco-friendly materials and designs that require less energy to operate.

- Integration of IoT: Linear bearings are being integrated into the Internet of Things (IoT) networks, allowing them to communicate with other equipment and systems for seamless automation and optimization.

- Magnetic Levitation Bearings: Magnetic levitation (maglev) technology is being applied to linear bearings to create frictionless movement, reducing wear and enabling smoother and more precise motion.

- Advanced Coatings: Coatings with enhanced wear resistance, low friction, and improved thermal properties are being applied to linear bearings, extending their service life in challenging environments.

These advancements have contributed to the expanding range of applications where linear bearings can be used, from aerospace and automotive industries to medical devices and consumer electronics. As technology continues to evolve, linear bearings will play a crucial role in enabling more efficient and precise motion control across various sectors.

Factors to Consider When Selecting a Linear Bearing

Choosing the right linear bearing for a specific application involves considering several critical factors to ensure optimal performance and longevity:

- Load Requirements:

Determine the magnitude and direction of the loads the linear bearing will experience. Consider both static and dynamic loads to select a bearing with an appropriate load capacity.

- Precision and Accuracy:

For applications requiring precise positioning, choose linear bearings with high precision and low backlash. Factors like repeatability and positional accuracy are crucial.

- Speed and Acceleration:

Consider the speed and acceleration at which the linear bearing will operate. Higher speeds may require bearings with lower friction and better heat dissipation.

- Environmental Conditions:

Assess the environmental factors such as temperature, humidity, and exposure to contaminants. Choose linear bearings with suitable materials and seals to withstand the conditions.

- Space Constraints:

Take into account the available space for mounting the linear bearing. Some applications may have limited space, necessitating compact and lightweight bearing options.

- Maintenance Requirements:

Consider the maintenance needs of the bearing. Bearings with self-lubricating properties or easy access for lubrication can reduce maintenance frequency.

- Mounting and Configuration:

Choose a linear bearing that can be easily mounted and integrated into your system’s design. Consider factors like mounting orientation and available mounting surfaces.

- Life Expectancy:

Estimate the expected lifespan of the linear bearing based on the application’s requirements. Select a bearing with a suitable design life to prevent premature failures.

- Cost and Budget:

Balance the desired performance with the available budget. Opt for linear bearings that provide the necessary features without exceeding cost limitations.

- Accessories and Add-ons:

Consider any additional accessories or add-ons, such as seals, lubrication systems, or end caps, that can enhance the bearing’s performance and protection.

- Manufacturer and Supplier:

Choose reputable manufacturers and suppliers that offer reliable products and good customer support. Quality assurance and technical assistance are essential.

Overall, a comprehensive assessment of these factors will help you select the most suitable linear bearing for your specific application, ensuring optimal performance, longevity, and cost-effectiveness.

editor by CX 2024-05-15

China manufacturer Wj838 OEM China Made NSK/NTN/Timken/Koyo/NACHI Machine/Auto/Motorcycle Parts Wheel Inch Taper/Tapered/Spherical/Cylindrical/Needle/Thrust/Linear Roller Bearing bearing and race

Product Description

Product Description

WHY CHOOSE E-ASIA BEARING?

1) 20 years of rich bearing industry export experience

2) ISO & MPA & CE & SGS & BV certified

3) Professional engineers team and Superior machines

4) 1 hour to HangZhou port or ZheJiang port

5) Strict quality inspection (3 steps) before shipment, such as SGS/BV third party certified.

CHOOSE E-ASIA REFUSED ONE TIME BUSINESS

| Deep groove ball bearing | 5 88506 88507 88508A 88508 88509 622 62303 62304 62305 62306 62307 62308 62309 62310 |

| Taper roller bearings | 35712 35713 35714 35715 35716 35717 35718 35719 35710 35711 35712 35713 35714 35715 35716 35717 35718 35719 35710 35711 35712 35714 35716 35718 35710 35712 35714 35716 35710 35714 30302 30303 30304 30305 30306 30307 30308 3 3 0571 3 0571 3 0 30321 30322 30324 30326 30328 30330 30332 30334 32204 32205 32206 32207 32208 32209 32210 32211 32212 32213 32214 32215 32216 32217 32218 32219 32220 32221 32222 32224 32226 32228 32230 32232 32236 32238 32240 32244 32248 32303 32304 32305 32306 32307 32308 32309 32310 32311 32312 32313 32314 32315 32316 32317 32318 32319 32320 32321 32322 32324 32326 32330 32334 31303 31304 31305 31306 31307 31308 31309 31310 31311 31312 31313 31314 31315 31316 31317 31318 31319 31320 31324 31326 31328 31332 32 325714 320726 325718 53856k 53860 |

| Self-aligning ball bearings | |

| spherical plain bearing | GE4E GE5E GE6E GE8E GE10E GE12E GE15ES GE17ES GE20ES GE25ES GE30ES GE35ES GE40ES GE45ES GE50ES GE60ES GE70ES GE80ES GE90ES GE1 110145 120155 130170 140180 150190 165710 |

| Thrust ball bearing | 511 234415 234416 234417 234418 234419 234420 234421 234422 234424 234426 234428 234430 234432 234438 234440 234714 234715 234716 234717 234718 234719 234720 234721 234722 234722 347262 347282 347302 347322 347382 34740 |

| Cylindrical Roller Bearings | NU313EMA NU2313EMA NU2314EMA NU415EMA NU216EMA NU2216EMA NJ2216EMA NUP2216EMA NU316EMA NU2316EMA NU217EMA NU2217EMA NU317EMA NU2317EMA NJ2317EMA NU218EMA NJ218EMA NU2218EMA NJ2218EMA NUP2218EMA NU318EMA NJ318EMA NU2318EMA NJ2318EMA NU219EMA NJ219EMA NU2219EMA NJ2219EMA NU319EMA NJ319EMA NU2319EMA NJ2319EMA NU220EMA NJ220EMA NU2220EMA NJ2220EMA NU320EMA NJ320EMA NU2320EMA NJ2320EMA NU222EMA NJ222EMA NU2222EMA NJ2222EMA NU322EMA NJ322EMA NU2322EMA NJ2322EMA NU1571MA NU224EMA NJ224EMA NU2224EMA NJ2224EMA NU324EMA NJ324EMA NU2324EMA NJ2324EMA NU1026MA NU226EMA NJ226EMA NU2226EMA NJ2226EMA NU326EMA NJ326EMA NU2326EMA NJ2326EMA NU1571MA NU228EMA NJ228EMA NU2228EMA NJ2228EMA NU328EMA NJ328EMA NU2328EMA NJ2328EMA NU1030MA NU230EMA NJ230EMA NUP230EMA NU2230EMA NJ2230EMA N2230EMB NU330EMA NJ330EMA NU2330EMA NJ2330EMA NU1032MA NU232EMA NJ232EMA NUP232EMA NU2232EMA NJ2232EMA NU332EMA NJ332EMA NU2332EMA NJ2332EMA NU1034MA NU3034EMA NU234EMA NJ234EMA NU2234EMA NJ2234EMA NU334EMA NJ334EMA NU2334EMA NJ2334EMA NU1036MA NU236EMA NJ236EMA NU2236EMA NJ2236EMA NU336EMA NJ336EMA NU2336EM NJ2336EMA NU1038MA NU238EMA NJ238EMA NU2238EMA NJ2238EMA NU338EMA NJ338EMA NU2338EMA NJ2338EMA NU1040MA NU240EMA NJ240EMA NU2240EMA NJ2240EMA NU340EMA NJ340EMA NU2340EMA NJ2340EMA NU1044MA NJ1044MA NU3044EMA NU244EMA NJ244EMA NU2244EMA NJ2244EMA NU344EMA NJ344EMA NU2344EMA NJ2344EMA N2344EMB NU1048MA NU248EMA NJ248EMA NU348EMA NJ348EMA NU2348EMA NJ2348EMA NU1052MA NU3052MA NU252MA NUP252MA NU2252MA NU2352EMA NU1056MA NU1060MA NU1964MA NF2964EMB NU1064MA NU2264MA NF2968EMB NU1068MA NU3068EMA NU3168EMA NU2372EMA NU1072MA NU1076MA NJ2980EMA NU1080MA NU2080EMA NF2984EMB NU1088MA NU2088EMA NU3188EMA NJ2892EMA NF2992EMB NU3192EMA NU1096EMA NJ1096EMA NU31/500EMA NU18/560MA NU30/600EMA NU20/630EMA NU20/670EMA NU20/670EMA NU30/670EMA NJ28/710EMA NJ29/710MA NU20/750EMA NU20/800EMA NU20/850EMA NU39/900EMA NU20/900EMA NJ18/1120EMA105RU32 105RN32 105RJ32 105RF32 105RT32 170RU51 170RN51 170RJ51 170RF51 170RT51 170RU91 170RN91 170RJ91 170RF91 170RT91 170RU93 170RN93 170RJ93 170RF93 170RT93 180RU51 180RN51 180RJ51 180RF51 180RT51 180RU91 180RN91 180RJ91 180RF91 180RT91 190RU91 190RN91 190RJ91 190RF91 190RT91 190RU92 190RN92 190RJ92 190RF92 190RT92 200RU91 200RN91 200RJ91 200RF91 200RT91 200RU92 200RN92 200RJ92 200RF92 200RT92 210RU92 210RN92 210RJ92 210RF92 210RT92 220RU51 220RN51 220RJ51 220RF51 220RT51 220RU91 220RN91 220RJ91 220RF91 220RT91 220RU92 220RN92 220RJ92 220RF92 220RT92 240RU91 240RN91 240RJ91 240RF91 240RT91 250RU91 250RN91 250RJ91 250RF91 250RT91NCF2922V NCF2924V NCF2926V NCF2928V NCF2930V NCF2932V NCF2934V NCF2936V NCF2938V NCF1840V NCF2940V NCF1844V NCF2944V NCF1852V NCF2952V NCF2960V NCF1864V NCF2964V NCF1868V NCF1876V NCF2976V NCF1880V NCF1884V NCF1888V NCF1892V NCF2992V NCF2996V NCF18/500V NCF29/500V NCF18/530V NCF18/560V NCF18/600V NCF18/630V NCF18/670V NCF18/710V NCF18/750V NCF18/800VNNU4930MAW33 NNU4932MAW33 NNU4934MAW33 NNU4936MAW33 NNU4938MAW33 NNU4940MAW33 NNU4140MAW33 NNU4944MAW33 NNU4144MAW33 NNU4948MAW33 NNU4148MAW33 NNU4952MAW33 NNU4152MAW33 NNU4956MAW33 NNU4156MAW33 NNU4960MAW33 NNU4160MAW33 NNU4964MAW33 NNU4164MAW33 NNU4968MAW33 NNU4068MAW33 NNU4168MAW33 NNU4972MAW33 NNU4072MAW33 NNU4172MAW33 NNU4976MAW33 NNU4076MAW33 NNU4176MAW33 NNU4980MAW33 NNU4080MAW33 NNU4180MAW33 NNU4984MAW33 NNU4084MAW33 NNU4184MAW33 NNU4988MAW33 NNU4088MAW33 NNU4188MAW33 NNU4992MAW33 NNU4092MAW33 NNU4192MAW33 NNU4996MAW33 NNU4096MAW33 NNU4196MAW33 NNU49/500MAW33 NNU40/500MAW33 NNU49/530MAW33 NNU40/530MAW33 NNU49/560MAW33 NNU49/600MAW33 NNU49/630MAW33 NNU49/670MAW33 NNU40/670MAW33 NNU49/710MAW33 NNU49/750MAW33 NNU49/800MAW33 NNU49/850MAW33 NNU49/900MAW33 |

Company Profile

E-Asia was set up in 1996 and located at HangZhou, a beautiful city in China. Our company is bearing manufacturer and NSK CZPT CZPT CZPT CZPT HRB LYC NACHI C&U bearing distributor. We also provide OEM beaings.Since it was first established, E-AISA was dedicated in research, development and manufacture of bearings. Now, E-AISA has become main and 1 of the first grade suppliers of all kinds of bearings.

Our products include: Deep Groove Ball Bearings, Self-aligning Ball Bearings, Spherical Bearings, Tapered Roller Bearings,Cylindrical Roller Bearings, Needle Roller Bearings, Self-aligning Roller Bearings, Angular Contact Ball Bearings, Thrust Ball Bearings and Trust Roller Bearings and Special Bearings.

E-Asia is a backbone enterprise for bearing production in China. With an area of 60, 000 square meters, more than 260 sets devices and machines, and around 200 employees, our company annually turns out more than 6 million sets bearings.

Our Bearings are exported to the USA, Canada, UK, Germany, Poland, Italy, Russia, the Middle East, Africa and other countries and regions of the world. E-Asia Bearing Co. Ltd. Is committed to the introduction of high-quality bearing products. Our company have more than 200 employees.

Our brands include ZWZ bearings, CZPT bearings, CZPT bearings, CZPT bearings, CZPT bearings, CZPT bearings and so forth.

Our belief is “Specialization is quality; Quality is the future. Any product with 0.01% defect is 100% reject” is our quality policy.

Packaging & Shipping

FAQ

1.What is the minimum order quantity for this product?

Can be negotiated, we will try our best to meet customer needs.Our company is mainly based on wholesale sales, most customers’orders are more than 1 ton.

2.What is your latest delivery time?

Most orders will be shipped within 3-5 days of payment being received.

3.Does your company have quality assurance?

Yes, for 2 years.

4.What is the competitiveness of your company’s products compared to other companies?

High precision, high speed, low noise.

5.What are the advantages of your company’s services compared to other companies?

Answer questions online 24 hours a day, reply in a timely manner, and provide various documents required by customers for customs clearance or sales. 100% after-sales service.

6.Which payment method does your company support?

Do our best to meet customer needs, negotiable.

7.How to contact us quickly?

Please send us an inquiry or message and leave your other contact information, such as phone number, account or account, we will contact you as soon as possible and provide the detailed information you need.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Auto Clutch Bearing |

|---|---|

| Material: | Chrome Steel |

| Tolerance: | P5 |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Contribution of Linear Bearings to CNC Machining Efficiency and Accuracy

Linear bearings play a crucial role in enhancing the efficiency and accuracy of Computer Numerical Control (CNC) machining processes. Here’s how they contribute:

- 1. Enhanced Precision:

Linear bearings provide smooth and precise linear motion along machine axes. This precision is essential for achieving tight tolerances and accurate dimensions in machined parts.

- 2. Reduced Friction and Wear:

Low friction in linear bearings minimizes energy loss and heat generation during movement. This reduces wear on the components and extends the lifespan of the machine, resulting in consistent performance over time.

- 3. Smooth Motion Control:

Linear bearings enable controlled and predictable motion, allowing CNC machines to execute complex tool paths with smooth transitions. This is crucial for producing intricate shapes and achieving high-quality surface finishes.

- 4. Minimized Vibration and Noise:

The smooth operation of linear bearings reduces vibration and noise levels during machining. This is especially important for maintaining a stable machining environment and producing parts with minimal surface imperfections.

- 5. Rapid Traverse Speeds:

Linear bearings facilitate rapid movements of machine components between machining operations. This increases the efficiency of the machining process, reducing cycle times and increasing overall productivity.

- 6. High Acceleration and Deceleration:

Linear bearings allow CNC machines to accelerate and decelerate rapidly without sacrificing precision. This capability is advantageous for optimizing machining time while maintaining accuracy.

- 7. Improved Repeatability:

Linear bearings ensure consistent and repeatable motion, resulting in parts that match design specifications precisely across multiple production runs.

- 8. Flexibility in Design:

Linear bearings enable the design of compact and space-efficient CNC machines. Their small footprint allows for more efficient use of manufacturing floor space.

In summary, linear bearings significantly enhance CNC machining by providing accurate, smooth, and controlled motion. This translates into higher precision, reduced wear, improved surface finishes, and increased productivity. Whether it’s milling, turning, or other CNC processes, linear bearings are essential for achieving the level of accuracy and efficiency demanded by modern manufacturing.

Contribution of Linear Bearings to Smooth Movement of Conveyors and Slides

Linear bearings play a crucial role in ensuring the smooth movement and operation of industrial conveyors and linear slides. Their contributions are as follows:

- Reduced Friction:

Linear bearings are designed to minimize friction between moving components, facilitating smooth motion of conveyors and linear slides. This reduces wear and tear, energy consumption, and the need for frequent maintenance.

- Precision Movement:

Linear bearings enable precise positioning and controlled movement. This precision is vital for conveyors and slides that require accurate placement of materials, products, or components.

- Stability and Load Distribution:

Linear bearings distribute loads evenly across the bearing surface, enhancing stability and preventing uneven wear. This is especially important for conveyors that handle varying loads and linear slides that support heavy components.

- Quiet and Vibration-Free Operation:

Linear bearings contribute to quiet and vibration-free operation. This is crucial in environments where noise reduction and minimal vibrations are essential for the comfort of operators and the integrity of products.

- Efficient Energy Transfer:

Linear bearings ensure efficient energy transfer by reducing energy losses due to friction. This efficiency is particularly beneficial in systems where multiple conveyors or slides are connected, improving overall system performance.

- Longevity and Reliability:

Linear bearings enhance the longevity and reliability of conveyors and slides by reducing wear on moving parts. This results in extended operational lifespans and reduced downtime for maintenance.

- Flexibility and Customization:

Linear bearings come in various designs and sizes, allowing for customization to suit specific conveyor or slide requirements. This adaptability is valuable for accommodating different loads and motion profiles.

- Wide Range of Industries:

Linear bearings find application in industries such as manufacturing, logistics, packaging, and material handling, where conveyors and linear slides are essential components of the workflow.

In summary, linear bearings contribute significantly to the efficient, precise, and reliable movement of industrial conveyors and linear slides. Their ability to reduce friction, ensure stability, and support heavy loads enhances the overall performance of these systems.

Advantages of Linear Bearings over Other Bearing Types

Linear bearings offer several distinct advantages when compared to other types of bearings, particularly in applications that require controlled linear motion. These benefits contribute to their widespread use across various industries:

- Precise Linear Motion:

Linear bearings are designed specifically for linear motion, providing accurate and controlled movement along a defined path. This precision is essential in applications that demand accurate positioning and repeatability.

- Low Friction:

Linear bearings are designed to minimize friction during motion. The reduced friction translates to smoother movement, reduced wear, and improved efficiency, making them suitable for applications requiring consistent motion.

- High Load Capacity:

Linear bearings can handle significant loads in both radial and axial directions. This capability allows them to support heavy components and maintain stability under various loads.

- Minimal Maintenance:

Due to their design and minimal contact between moving parts, linear bearings require less maintenance compared to other types of bearings. This is particularly advantageous in hard-to-reach or inaccessible areas.

- Guided Motion:

Linear bearings provide guided and constrained motion along a single axis. This guidance eliminates the need for complex guiding mechanisms, reducing design complexity and simplifying assembly.

- Compact Design:

Linear bearings have a compact form factor, making them suitable for applications with limited space. Their small footprint allows for efficient use of available area.

- Low Noise and Vibration:

Linear bearings generate minimal noise and vibration during operation, contributing to quieter and more comfortable working environments in applications such as medical devices and precision machinery.

- Smooth Movement:

Linear bearings offer smooth and consistent movement, essential for applications requiring continuous and controlled motion, such as robotic systems and conveyor belts.

- Customization:

Linear bearings can be designed to fit specific application requirements, including load capacity, travel distance, and environmental conditions. This customization enhances their suitability for diverse applications.

- Reduced Wear:

The low friction and guided motion of linear bearings result in reduced wear on both the bearing and the mating surface, leading to longer service life and reduced maintenance costs.

Overall, the benefits of using linear bearings make them a preferred choice in applications that demand accurate linear motion, efficient load handling, and reduced maintenance. Their ability to deliver precision, stability, and reliability contributes to improved performance across various industries.

editor by CX 2024-05-07

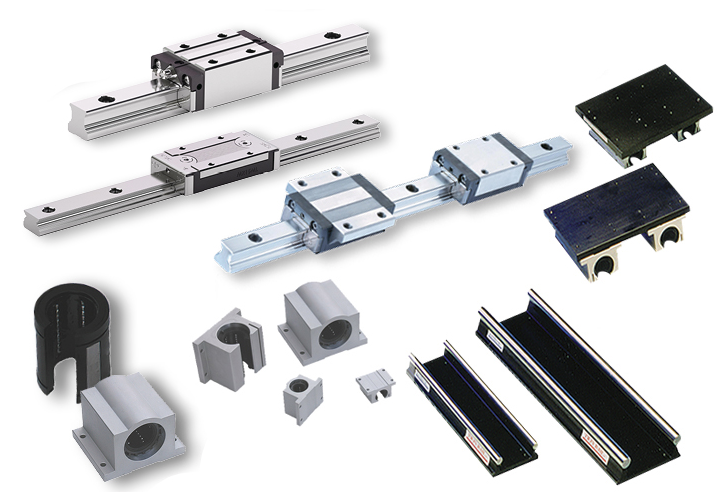

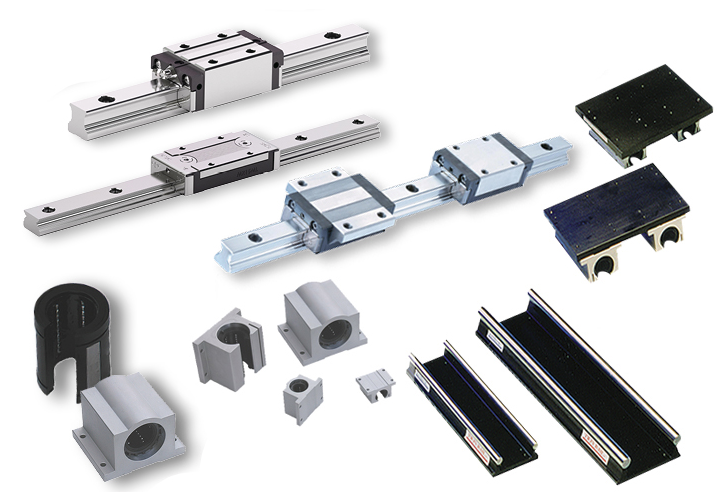

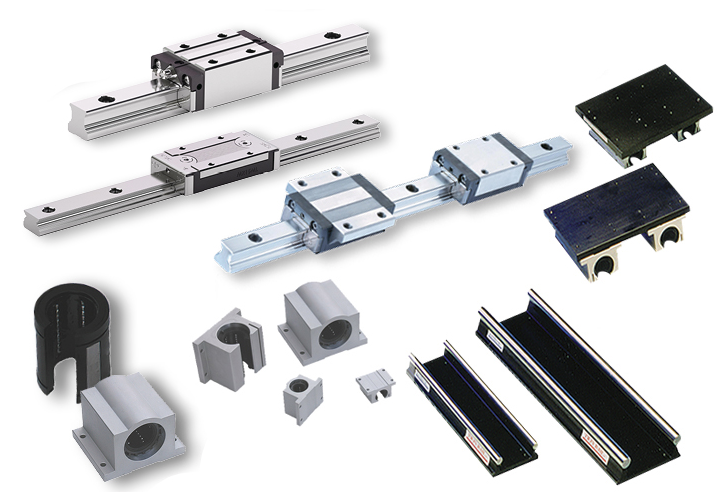

China OEM Linear Drive Traverse Units Assembly Load Carrier Linear Bearing wheel bearing

Product Description

Product Description

Linear Drive Traverse Units Assembly Load Carrier Linear Bearing

Manufacturer of automatic linear transmission gear with well-equipped testing facilities and strong technical force

Detailed Photos

Packaging & Shipping

|

Package Material

|

Carton |

|

Package Detail

|

10 pieces or 5 pieces per pag |

|

Delivery Way |

Deliver the goods by express, like UPS, DHL, FedEx or by sea shipment or according to customer’s requirement |

Product Application

Special Bearing for Rolling Ring Traverse Drive

Company Profile

ZheJiang Xihu (West Lake) Dis. Machinery Co., Ltd.

A manufacturer of automatic linear transmission gear with well-equipped testing facilities and strong technical force.

We are producing and selling: rolling ring drives, linear drives, linear drives nut, wire straightener, automatic wire straightening and cutting machine, automatic coiling & packaging machine, drawing and rolling machine, automatic yarn winding machine and accessories for rolling ring drives.

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in carton boxes or wooden boxes.

Q2. What is your terms of payment?

A: T/T 100% paymeny in advance, or 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will send this product within 3 or 5 days after receiving your payment. The specific delivery time depends on the items and the quantity of your order.

Q5. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Core Components: | Roller Bearing |

|---|---|

| Transport Package: | Carton |

| Specification: | Bearing steel |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Challenges and Solutions for Addressing Friction and Wear in Linear Bearings

Friction and wear are common challenges in linear bearings that can impact their performance and lifespan. Here are the challenges and some solutions to address them:

- 1. Challenge: Friction:

Friction between the bearing components can lead to increased energy consumption, heat generation, and reduced efficiency.

- Solution: Lubrication:

Proper lubrication is essential to minimize friction. Lubricants reduce the contact between moving parts, allowing smoother motion and reducing wear. Choosing the right lubricant and applying it correctly can significantly mitigate friction-related issues.

- 2. Challenge: Wear:

Continuous movement can lead to wear on the bearing surfaces, affecting precision and performance over time.

- Solution: Regular Maintenance:

Implementing a regular maintenance schedule can help monitor wear and replace worn components before they compromise performance. This includes cleaning, re-lubrication, and periodic inspection of the bearing’s condition.

- 3. Challenge: Contaminants:

Dust, debris, and foreign particles can enter the bearing system, leading to increased friction and accelerated wear.

- Solution: Sealing and Protection:

Using seals, covers, or protective enclosures can help prevent contaminants from entering the bearing system. These protective measures maintain the integrity of the lubricant and extend the bearing’s lifespan.

- 4. Challenge: Improper Installation:

If linear bearings are not installed correctly, misalignment and uneven load distribution can contribute to friction and wear.

- Solution: Precise Installation:

Follow manufacturer guidelines for proper installation, ensuring accurate alignment and even load distribution. This reduces the risk of premature wear and ensures optimal performance.

- 5. Challenge: Inadequate Lubrication:

If the linear bearings are under-lubricated or over-lubricated, it can lead to increased friction and wear.

- Solution: Lubrication Management:

Monitor and manage lubrication levels to ensure they are within the recommended range. Regularly assess the lubricant’s condition and replenish as needed to maintain optimal performance.

- 6. Challenge: High Loads and Speeds:

High loads and speeds can increase friction and wear on linear bearings.

- Solution: Proper Selection:

Select linear bearings that are designed to handle the specific loads and speeds of the application. This ensures that the bearings can operate effectively under the given conditions.

Addressing friction and wear challenges in linear bearings requires a combination of proper maintenance practices, appropriate lubrication, protective measures, and careful selection of bearings. By implementing these solutions, the performance and longevity of linear bearings can be optimized.

Recent Advancements in Linear Bearing Technology

Recent years have seen significant advancements in linear bearing technology, leading to improved performance, reliability, and versatility. Some notable developments include:

- Nanotechnology: The integration of nanotechnology has allowed for the development of ultra-precision linear bearings with nanometer-scale accuracy. These bearings are ideal for applications requiring extremely fine movement and positioning.

- Smart Bearings: Advances in sensor technology have enabled the creation of smart linear bearings that can monitor parameters like temperature, load, and vibration in real time. This data helps in predictive maintenance and optimizing operational efficiency.

- Materials Innovation: New materials with enhanced properties, such as self-lubricating and corrosion-resistant coatings, have extended the lifespan of linear bearings and reduced the need for frequent lubrication and maintenance.

- Compact Designs: Manufacturers are designing more compact linear bearings to suit space-constrained applications while maintaining high load capacity and precision.

- Environmental Sustainability: There’s a growing emphasis on developing linear bearings with reduced environmental impact, including using eco-friendly materials and designs that require less energy to operate.

- Integration of IoT: Linear bearings are being integrated into the Internet of Things (IoT) networks, allowing them to communicate with other equipment and systems for seamless automation and optimization.

- Magnetic Levitation Bearings: Magnetic levitation (maglev) technology is being applied to linear bearings to create frictionless movement, reducing wear and enabling smoother and more precise motion.

- Advanced Coatings: Coatings with enhanced wear resistance, low friction, and improved thermal properties are being applied to linear bearings, extending their service life in challenging environments.

These advancements have contributed to the expanding range of applications where linear bearings can be used, from aerospace and automotive industries to medical devices and consumer electronics. As technology continues to evolve, linear bearings will play a crucial role in enabling more efficient and precise motion control across various sectors.

Design Principles and Functionalities of Linear Bearings

Linear bearings are designed with specific principles to facilitate controlled linear motion along a single axis. These design principles contribute to their functionalities, making them essential components in various applications:

- Rolling Elements:

Linear bearings typically feature rolling elements, such as balls or rollers, that move along a track or rail. These rolling elements reduce friction and enable smooth linear motion.

- Guiding Mechanism:

Linear bearings incorporate a guiding mechanism to constrain the motion to a single axis. This guiding mechanism ensures that the linear bearing moves precisely along the desired path.

- Load Distribution:

The design of linear bearings allows for effective distribution of loads, both in the radial and axial directions. This load distribution ensures stability and prevents excessive stress on individual components.

- Rail or Track:

Linear bearings typically run along a rail or track that provides a smooth and accurate path for the rolling elements. The rail is designed to resist wear and maintain its precision over time.

- Cage or Carriage:

Linear bearings use a cage or carriage to house the rolling elements and maintain their proper spacing. This arrangement ensures even load distribution and smooth movement.

- Sealing and Lubrication:

Linear bearings often incorporate sealing mechanisms to protect the rolling elements from contaminants and to retain lubrication. Proper lubrication ensures smooth motion and extends the bearing’s lifespan.

- Mounting Options:

Linear bearings are designed to be mounted in various ways, depending on the application’s requirements. Mounting options include flange-mounted, base-mounted, or end-supported configurations.

- Adjustability:

Many linear bearings are designed with provisions for adjustment, allowing users to fine-tune the preload or clearance to optimize performance and minimize play.

- Materials:

Linear bearings are constructed from materials that offer high wear resistance, durability, and corrosion resistance. Common materials include steel, stainless steel, and various engineering plastics.

- Accessories:

Accessories such as end caps, seals, and lubrication systems can enhance the functionality and lifespan of linear bearings by providing protection and ensuring proper maintenance.

Functionalities of linear bearings include providing precise linear motion, guiding components along a defined path, minimizing friction, distributing loads, and maintaining stability. The design principles ensure reliable operation and make linear bearings indispensable in applications requiring controlled and accurate linear motion.

editor by CX 2024-04-30

China OEM Linear Flat Rollers / Linear Flat Needle Roller Bearings BF3020/1000, BF5023/1000 bearing block

Product Description

Product Description

Flat Roller Cage is a limited linear motion CZPT consisting of high accuracy rollers and a very precise retainers and features low cross sectional height which is as high as the roller diameter.

Packaging & Shipping

Our Advantages

1. We have over 10 years’ experience.

2. OEM or Non-Standard Bearings: Any requirement for Non-standard bearings is easily fulfilled by us due to our vast knowledge and links in the industry.

3. After Sales Service and Technical Assistance: Our company provides after-sales service and technical assistance as per the customer’s requirements and needs.

4. Quick Delivery: Our company provides just-in-time delivery with our streamlined supply chain.

5.We attend promptly to any customer questions. We believe that if our customers are satisfied then it proves our worth. Our customers are always given quick support.

Please contact us immediately if you have any questions.

Related Products

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Cage: | With Cage |

|---|---|

| Rows Number: | Single |

| Style: | With Outer Ring |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Contribution of Linear Bearings to CNC Machining Efficiency and Accuracy

Linear bearings play a crucial role in enhancing the efficiency and accuracy of Computer Numerical Control (CNC) machining processes. Here’s how they contribute:

- 1. Enhanced Precision:

Linear bearings provide smooth and precise linear motion along machine axes. This precision is essential for achieving tight tolerances and accurate dimensions in machined parts.

- 2. Reduced Friction and Wear:

Low friction in linear bearings minimizes energy loss and heat generation during movement. This reduces wear on the components and extends the lifespan of the machine, resulting in consistent performance over time.

- 3. Smooth Motion Control:

Linear bearings enable controlled and predictable motion, allowing CNC machines to execute complex tool paths with smooth transitions. This is crucial for producing intricate shapes and achieving high-quality surface finishes.

- 4. Minimized Vibration and Noise:

The smooth operation of linear bearings reduces vibration and noise levels during machining. This is especially important for maintaining a stable machining environment and producing parts with minimal surface imperfections.

- 5. Rapid Traverse Speeds:

Linear bearings facilitate rapid movements of machine components between machining operations. This increases the efficiency of the machining process, reducing cycle times and increasing overall productivity.

- 6. High Acceleration and Deceleration:

Linear bearings allow CNC machines to accelerate and decelerate rapidly without sacrificing precision. This capability is advantageous for optimizing machining time while maintaining accuracy.

- 7. Improved Repeatability:

Linear bearings ensure consistent and repeatable motion, resulting in parts that match design specifications precisely across multiple production runs.

- 8. Flexibility in Design:

Linear bearings enable the design of compact and space-efficient CNC machines. Their small footprint allows for more efficient use of manufacturing floor space.

In summary, linear bearings significantly enhance CNC machining by providing accurate, smooth, and controlled motion. This translates into higher precision, reduced wear, improved surface finishes, and increased productivity. Whether it’s milling, turning, or other CNC processes, linear bearings are essential for achieving the level of accuracy and efficiency demanded by modern manufacturing.

Recent Advancements in Linear Bearing Technology

Recent years have seen significant advancements in linear bearing technology, leading to improved performance, reliability, and versatility. Some notable developments include:

- Nanotechnology: The integration of nanotechnology has allowed for the development of ultra-precision linear bearings with nanometer-scale accuracy. These bearings are ideal for applications requiring extremely fine movement and positioning.

- Smart Bearings: Advances in sensor technology have enabled the creation of smart linear bearings that can monitor parameters like temperature, load, and vibration in real time. This data helps in predictive maintenance and optimizing operational efficiency.

- Materials Innovation: New materials with enhanced properties, such as self-lubricating and corrosion-resistant coatings, have extended the lifespan of linear bearings and reduced the need for frequent lubrication and maintenance.

- Compact Designs: Manufacturers are designing more compact linear bearings to suit space-constrained applications while maintaining high load capacity and precision.

- Environmental Sustainability: There’s a growing emphasis on developing linear bearings with reduced environmental impact, including using eco-friendly materials and designs that require less energy to operate.

- Integration of IoT: Linear bearings are being integrated into the Internet of Things (IoT) networks, allowing them to communicate with other equipment and systems for seamless automation and optimization.

- Magnetic Levitation Bearings: Magnetic levitation (maglev) technology is being applied to linear bearings to create frictionless movement, reducing wear and enabling smoother and more precise motion.

- Advanced Coatings: Coatings with enhanced wear resistance, low friction, and improved thermal properties are being applied to linear bearings, extending their service life in challenging environments.

These advancements have contributed to the expanding range of applications where linear bearings can be used, from aerospace and automotive industries to medical devices and consumer electronics. As technology continues to evolve, linear bearings will play a crucial role in enabling more efficient and precise motion control across various sectors.

Design Principles and Functionalities of Linear Bearings

Linear bearings are designed with specific principles to facilitate controlled linear motion along a single axis. These design principles contribute to their functionalities, making them essential components in various applications:

- Rolling Elements:

Linear bearings typically feature rolling elements, such as balls or rollers, that move along a track or rail. These rolling elements reduce friction and enable smooth linear motion.

- Guiding Mechanism:

Linear bearings incorporate a guiding mechanism to constrain the motion to a single axis. This guiding mechanism ensures that the linear bearing moves precisely along the desired path.

- Load Distribution:

The design of linear bearings allows for effective distribution of loads, both in the radial and axial directions. This load distribution ensures stability and prevents excessive stress on individual components.

- Rail or Track:

Linear bearings typically run along a rail or track that provides a smooth and accurate path for the rolling elements. The rail is designed to resist wear and maintain its precision over time.

- Cage or Carriage:

Linear bearings use a cage or carriage to house the rolling elements and maintain their proper spacing. This arrangement ensures even load distribution and smooth movement.

- Sealing and Lubrication:

Linear bearings often incorporate sealing mechanisms to protect the rolling elements from contaminants and to retain lubrication. Proper lubrication ensures smooth motion and extends the bearing’s lifespan.

- Mounting Options:

Linear bearings are designed to be mounted in various ways, depending on the application’s requirements. Mounting options include flange-mounted, base-mounted, or end-supported configurations.

- Adjustability:

Many linear bearings are designed with provisions for adjustment, allowing users to fine-tune the preload or clearance to optimize performance and minimize play.

- Materials:

Linear bearings are constructed from materials that offer high wear resistance, durability, and corrosion resistance. Common materials include steel, stainless steel, and various engineering plastics.

- Accessories:

Accessories such as end caps, seals, and lubrication systems can enhance the functionality and lifespan of linear bearings by providing protection and ensuring proper maintenance.

Functionalities of linear bearings include providing precise linear motion, guiding components along a defined path, minimizing friction, distributing loads, and maintaining stability. The design principles ensure reliable operation and make linear bearings indispensable in applications requiring controlled and accurate linear motion.

editor by CX 2024-04-30

China OEM Linear Traverse Driving Device Ball Bearing for Winding Machinery with Good quality

Product Description

Product Description

Linear traverse driving device ball bearing for winding machinery

Manufacturer of automatic linear transmission gear with well-equipped testing facilities and strong technical force

Detailed Photos

Packaging & Shipping

|

Package Material

|

Carton |

|

Package Detail

|

10 pieces or 5 pieces per pag |

|

Delivery Way |

Deliver the goods by express, like UPS, DHL, FedEx or by sea shipment or according to customer’s requirement |

Product Application

Special Bearing for Rolling Ring Traverse Drive

Company Profile

ZheJiang Xihu (West Lake) Dis. Machinery Co., Ltd.

A manufacturer of automatic linear transmission gear with well-equipped testing facilities and strong technical force.

We are producing and selling: rolling ring drives, linear drives, linear drives nut, wire straightener, automatic wire straightening and cutting machine, automatic coiling & packaging machine, drawing and rolling machine, automatic yarn winding machine and accessories for rolling ring drives.

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in carton boxes or wooden boxes.

Q2. What is your terms of payment?

A: T/T 100% paymeny in advance, or 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will send this product within 3 or 5 days after receiving your payment. The specific delivery time depends on the items and the quantity of your order.

Q5. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Core Components: | Roller Bearing |

|---|---|

| Transport Package: | Carton |

| Specification: | Bearing steel |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Contribution of Linear Bearings to CNC Machining Efficiency and Accuracy

Linear bearings play a crucial role in enhancing the efficiency and accuracy of Computer Numerical Control (CNC) machining processes. Here’s how they contribute:

- 1. Enhanced Precision:

Linear bearings provide smooth and precise linear motion along machine axes. This precision is essential for achieving tight tolerances and accurate dimensions in machined parts.

- 2. Reduced Friction and Wear:

Low friction in linear bearings minimizes energy loss and heat generation during movement. This reduces wear on the components and extends the lifespan of the machine, resulting in consistent performance over time.

- 3. Smooth Motion Control:

Linear bearings enable controlled and predictable motion, allowing CNC machines to execute complex tool paths with smooth transitions. This is crucial for producing intricate shapes and achieving high-quality surface finishes.

- 4. Minimized Vibration and Noise:

The smooth operation of linear bearings reduces vibration and noise levels during machining. This is especially important for maintaining a stable machining environment and producing parts with minimal surface imperfections.

- 5. Rapid Traverse Speeds:

Linear bearings facilitate rapid movements of machine components between machining operations. This increases the efficiency of the machining process, reducing cycle times and increasing overall productivity.

- 6. High Acceleration and Deceleration:

Linear bearings allow CNC machines to accelerate and decelerate rapidly without sacrificing precision. This capability is advantageous for optimizing machining time while maintaining accuracy.

- 7. Improved Repeatability:

Linear bearings ensure consistent and repeatable motion, resulting in parts that match design specifications precisely across multiple production runs.

- 8. Flexibility in Design:

Linear bearings enable the design of compact and space-efficient CNC machines. Their small footprint allows for more efficient use of manufacturing floor space.

In summary, linear bearings significantly enhance CNC machining by providing accurate, smooth, and controlled motion. This translates into higher precision, reduced wear, improved surface finishes, and increased productivity. Whether it’s milling, turning, or other CNC processes, linear bearings are essential for achieving the level of accuracy and efficiency demanded by modern manufacturing.

Enhancing 3D Printers and Additive Manufacturing with Linear Bearings

Linear bearings play a crucial role in the efficient and precise operation of 3D printers and additive manufacturing processes. Here’s how they contribute to these technologies:

- Precise Motion Control:

Linear bearings provide smooth and accurate linear motion control, ensuring precise positioning of the print head or build platform. This precision is essential for creating intricate and detailed 3D printed objects.

- High Repeatability:

Linear bearings offer high repeatability, enabling the printer to consistently recreate complex geometries layer by layer. This is crucial for producing parts with consistent quality and dimensions.

- Reduced Vibration and Wobble:

The smooth motion provided by linear bearings minimizes vibrations and wobbling during printing, leading to smoother surface finishes and improved print quality.

- High-Speed Printing:

Linear bearings can handle high speeds, allowing 3D printers to operate at faster print speeds without sacrificing accuracy. This is beneficial for reducing overall print time.

- Compact Design:

Many linear bearings have a compact and space-efficient design, which is important for fitting within the confined spaces of 3D printers while maintaining the required range of motion.

- Low Friction and Wear:

Linear bearings are designed to minimize friction and wear, leading to longer lifespan and reduced maintenance requirements. This is especially important in additive manufacturing where continuous operation is desired.

- Smooth Layer-by-Layer Building:

In additive manufacturing, linear bearings enable precise movement of the build platform or print head, ensuring that each layer is accurately aligned and built upon the previous layer.

- Complex Geometries:

Linear bearings enable 3D printers to create complex and intricate geometries that require precise control over the movement of the print head and build platform.

Overall, linear bearings contribute to the success of 3D printing and additive manufacturing by providing the necessary motion control, precision, and reliability needed to create high-quality and intricate 3D printed objects.

Examples of Crucial Motion Control Scenarios Using Linear Bearings

Linear bearings are crucial for achieving precise motion control in various scenarios where accuracy, repeatability, and smooth movement are essential. Here are some examples:

- 1. CNC Machining:

In computer numerical control (CNC) machines, linear bearings enable precise movement of the cutting tool or workpiece along multiple axes. This accuracy is necessary to produce complex and intricate parts with tight tolerances.

- 2. Semiconductor Manufacturing:

In semiconductor fabrication equipment, linear bearings control the movement of wafers, masks, and other components with micron-level precision. This precision is vital for creating tiny circuits and microchips.

- 3. 3D Printing:

In 3D printers, linear bearings ensure accurate positioning of the print head and build platform. This accuracy is crucial for creating intricate and detailed 3D-printed objects.

- 4. Laser Cutting and Engraving:

Linear bearings are used in laser cutting and engraving machines to control the movement of the laser head. Precise motion ensures accurate cutting and engraving on various materials.

- 5. Microscopy:

In microscopy applications, linear bearings enable precise positioning of microscope stages and objectives. This accuracy is essential for capturing detailed images and conducting precise measurements.

- 6. Metrology and Inspection:

Linear bearings are crucial in metrology and inspection equipment for accurately measuring and inspecting parts. This ensures compliance with quality standards and specifications.

- 7. Optical Systems:

In optical systems, linear bearings control the movement of lenses, mirrors, and other optical components. Precise motion is essential for maintaining accurate focus and alignment.

- 8. Coordinate Measuring Machines (CMMs):

Linear bearings in CMMs allow accurate measurement of parts’ dimensions and geometries. Precise motion ensures reliable measurement results.

- 9. Aerospace and Defense Testing:

In aerospace and defense industries, linear bearings are used in testing equipment to simulate various conditions. Accurate motion control is crucial for testing components’ performance and durability.

These examples highlight the critical role of linear bearings in achieving precise motion control across industries. Whether in manufacturing, research, or testing, linear bearings ensure accurate and repeatable movement for optimal results.

editor by CX 2024-04-08

China Custom OEM Hot Sale Long Life Linear Bearing for CNC Machine with high quality

Product Description

Company Profile

UP GOLD Automation Technology Co., LTD., independent brand, NYZ and UP. The main products are linear CZPT rail, slider, ball screw, linear optical shaft, linear bearing, machine tool spindle special P4 high precision bearings and accessories, with advanced production equipment and testing instruments to ensure the accuracy of each product. Precision products will provide higher value to the equipment. The company promises to sell each product, warranty period of 24 months, 24 hours after-sales service. Provide professional OEM cooperation model. At the same time, the company agents international first-line brands HIWIN, TBI, NSK,THK. Sufficient resources to ensure every customer needs.

Our Advantages

*Two-year warranty, replace instead of repair.

*12 Months Warranty

*Fast Delivery

*24 hours on line service

*Professional Team

Product Description

Linear bearings are widely used in electronic equipment, tensile testing machine and digital 3D coordinate measuring equipment, and multi axis machine, punching machine, tool grinding machine, automatic cutting machine, printer, card sorting machine, food packaging machine industry machinery sliding parts.

| Product Name |

Bxy China factory induction hardened chrome linear shaft |

| Model Number |

WC10 |

| Size |

30*45*64mm |

| Feature |

1.High performance 2.High rigidity 3.High power 5.Easy maintenance |

| Precision |

High Precision |

| Material |

Chrome Steel GCr15 |

| Delivery Time |

1) 1-5 Workdays for Samples or in Stock 2) 10-30 Working Days for Ordering |

Customer Comment

Packaging & Shipping

Bearing packaging mode

01 Industrial packaging

Plastic tube + Carton + Pallet

02 Commercial packaging

Plastic bag + Kraft paper+ Carton+ Pallet

03 Original packing+ pallet

Mode Of Transportation

Air freight

Less than 45 KGS,we will send by express.

(Door to Door,Convenient)

Land transportation

Between 45- 150 KGS, we will send by air transport.

(Fastest and safest, but expensive)

Railway

More than 150 KGS,we will send by sea.

Shipping

According to the requirement of customer.

FAQ

Q: What is the producing process?

A: Production process including raw material cutting, machine processing,grinding, accessories cleaning, assemble, cleaning, oil coating,cover pressing, testing, package.

Q: How to control the products quality?

A: Combining advanced equipment and strict management, we provide high standard and quality bearings for our customers all over the world.

Q: What is the transportation?

A: If small quantity, we suggest to send by express, such as DHL, UPS,TNT FEDEX. If large amount, by air or sea shipping.

Q: How about the shipping charge?

A: We will be free of domestic shipping charge from your freight forwarder in China.

Q: Can you provide OEM service?

A: Yes, we provide OEM service. Which means size, quantity, design,packing solution, etc will depend on your requests; and your logo will be customized on our products.

Q: Could you tell me the delivery time of your goods?

A: Generally it is 3-5 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to the quantity.

Q: What about the packaging of your products?

A: Normally we use standard commercial package, we also have our own brand packing or customized package as per customers’ requests.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Vacuum, Magnetically, Low Temperature, Corrosion Resistant, High Temperature, High Speed |

|---|---|

| Function: | Ordinary |

| Flange Shape: | Oval |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Considerations for Selecting the Right Type and Size of Linear Bearing

Choosing the appropriate type and size of linear bearing requires careful consideration of various factors to ensure optimal performance and compatibility with the application. Here are important considerations to keep in mind:

- 1. Load Capacity:

Determine the maximum load the linear bearing will need to support. Consider both static and dynamic loads to select a bearing that can handle the expected weight and forces.

- 2. Speed and Acceleration:

Assess the required speed and acceleration of the linear motion. Different linear bearing types have different speed limitations, so choose one that can accommodate the desired motion profile.

- 3. Precision and Accuracy:

If your application requires precise positioning, choose linear bearings that offer high accuracy and repeatability. Linear ball bearings are known for their precision, while linear roller bearings offer higher load capacity.

- 4. Environment:

Consider the operating environment, including temperature, humidity, dust, and potential exposure to chemicals. Select linear bearings that are designed to withstand the specific environmental conditions.

- 5. Rail or Shaft Compatibility:

Ensure that the chosen linear bearing is compatible with the rail or shaft you intend to use. Proper fit and alignment are crucial for smooth motion and long bearing life.

- 6. Space Constraints:

If your application has limited space, choose compact linear bearings that can fit within the available area without compromising performance.

- 7. Maintenance Requirements:

Consider the level of maintenance your application can accommodate. Some linear bearings are self-lubricating, reducing the need for frequent maintenance.

- 8. Noise Level:

For noise-sensitive environments, opt for linear bearings that provide quiet operation to avoid disruptions caused by excessive noise.

- 9. Mounting Options:

Consider how the linear bearing will be mounted and integrated into your system. Different bearings may require specific mounting configurations.

- 10. Cost and Budget:

Balance the desired features and performance with your budget constraints. While high-performance linear bearings may offer advanced features, they can also come at a higher cost.

By carefully evaluating these factors, you can choose the most suitable type and size of linear bearing for your specific application. Consulting with bearing manufacturers and engineers can also provide valuable insights to ensure the optimal selection.

Role of Linear Bearings in Heavy Load and High Precision Applications

Linear bearings are essential components in applications that require the combined capabilities of handling heavy loads and maintaining high precision. They serve a critical role in such scenarios:

- Heavy Load Handling:

Linear bearings are designed to support and guide heavy loads along a linear path. They distribute the weight evenly, reducing friction and wear on the moving components and ensuring smooth and stable movement.

- Precision Motion Control:

Linear bearings enable precise and accurate control over the motion of heavy loads. This precision is crucial in applications where components need to be positioned or moved with extremely fine tolerances.

- Reduced Friction:

Linear bearings are engineered to minimize friction between moving parts, even under heavy load conditions. This not only improves efficiency but also enhances the accuracy of movement.