Product Description

Product Description

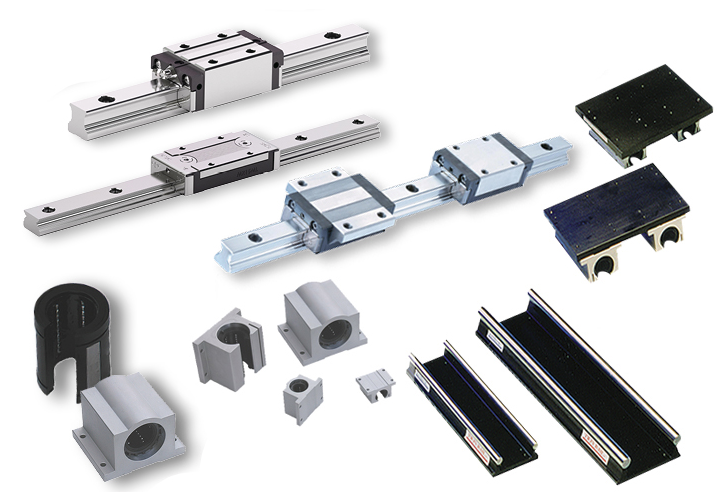

Linear Drive Traverse Units Assembly Load Carrier Linear Bearing

Manufacturer of automatic linear transmission gear with well-equipped testing facilities and strong technical force

Detailed Photos

Packaging & Shipping

|

Package Material

|

Carton |

|

Package Detail

|

10 pieces or 5 pieces per pag |

|

Delivery Way |

Deliver the goods by express, like UPS, DHL, FedEx or by sea shipment or according to customer’s requirement |

Product Application

Special Bearing for Rolling Ring Traverse Drive

Company Profile

ZheJiang Xihu (West Lake) Dis. Machinery Co., Ltd.

A manufacturer of automatic linear transmission gear with well-equipped testing facilities and strong technical force.

We are producing and selling: rolling ring drives, linear drives, linear drives nut, wire straightener, automatic wire straightening and cutting machine, automatic coiling & packaging machine, drawing and rolling machine, automatic yarn winding machine and accessories for rolling ring drives.

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in carton boxes or wooden boxes.

Q2. What is your terms of payment?

A: T/T 100% paymeny in advance, or 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will send this product within 3 or 5 days after receiving your payment. The specific delivery time depends on the items and the quantity of your order.

Q5. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Core Components: | Roller Bearing |

|---|---|

| Transport Package: | Carton |

| Specification: | Bearing steel |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Challenges and Solutions for Addressing Friction and Wear in Linear Bearings

Friction and wear are common challenges in linear bearings that can impact their performance and lifespan. Here are the challenges and some solutions to address them:

- 1. Challenge: Friction:

Friction between the bearing components can lead to increased energy consumption, heat generation, and reduced efficiency.

- Solution: Lubrication:

Proper lubrication is essential to minimize friction. Lubricants reduce the contact between moving parts, allowing smoother motion and reducing wear. Choosing the right lubricant and applying it correctly can significantly mitigate friction-related issues.

- 2. Challenge: Wear:

Continuous movement can lead to wear on the bearing surfaces, affecting precision and performance over time.

- Solution: Regular Maintenance:

Implementing a regular maintenance schedule can help monitor wear and replace worn components before they compromise performance. This includes cleaning, re-lubrication, and periodic inspection of the bearing’s condition.

- 3. Challenge: Contaminants:

Dust, debris, and foreign particles can enter the bearing system, leading to increased friction and accelerated wear.

- Solution: Sealing and Protection:

Using seals, covers, or protective enclosures can help prevent contaminants from entering the bearing system. These protective measures maintain the integrity of the lubricant and extend the bearing’s lifespan.

- 4. Challenge: Improper Installation:

If linear bearings are not installed correctly, misalignment and uneven load distribution can contribute to friction and wear.

- Solution: Precise Installation:

Follow manufacturer guidelines for proper installation, ensuring accurate alignment and even load distribution. This reduces the risk of premature wear and ensures optimal performance.

- 5. Challenge: Inadequate Lubrication:

If the linear bearings are under-lubricated or over-lubricated, it can lead to increased friction and wear.

- Solution: Lubrication Management:

Monitor and manage lubrication levels to ensure they are within the recommended range. Regularly assess the lubricant’s condition and replenish as needed to maintain optimal performance.

- 6. Challenge: High Loads and Speeds:

High loads and speeds can increase friction and wear on linear bearings.

- Solution: Proper Selection:

Select linear bearings that are designed to handle the specific loads and speeds of the application. This ensures that the bearings can operate effectively under the given conditions.

Addressing friction and wear challenges in linear bearings requires a combination of proper maintenance practices, appropriate lubrication, protective measures, and careful selection of bearings. By implementing these solutions, the performance and longevity of linear bearings can be optimized.

Recent Advancements in Linear Bearing Technology

Recent years have seen significant advancements in linear bearing technology, leading to improved performance, reliability, and versatility. Some notable developments include:

- Nanotechnology: The integration of nanotechnology has allowed for the development of ultra-precision linear bearings with nanometer-scale accuracy. These bearings are ideal for applications requiring extremely fine movement and positioning.

- Smart Bearings: Advances in sensor technology have enabled the creation of smart linear bearings that can monitor parameters like temperature, load, and vibration in real time. This data helps in predictive maintenance and optimizing operational efficiency.

- Materials Innovation: New materials with enhanced properties, such as self-lubricating and corrosion-resistant coatings, have extended the lifespan of linear bearings and reduced the need for frequent lubrication and maintenance.

- Compact Designs: Manufacturers are designing more compact linear bearings to suit space-constrained applications while maintaining high load capacity and precision.

- Environmental Sustainability: There’s a growing emphasis on developing linear bearings with reduced environmental impact, including using eco-friendly materials and designs that require less energy to operate.

- Integration of IoT: Linear bearings are being integrated into the Internet of Things (IoT) networks, allowing them to communicate with other equipment and systems for seamless automation and optimization.

- Magnetic Levitation Bearings: Magnetic levitation (maglev) technology is being applied to linear bearings to create frictionless movement, reducing wear and enabling smoother and more precise motion.

- Advanced Coatings: Coatings with enhanced wear resistance, low friction, and improved thermal properties are being applied to linear bearings, extending their service life in challenging environments.

These advancements have contributed to the expanding range of applications where linear bearings can be used, from aerospace and automotive industries to medical devices and consumer electronics. As technology continues to evolve, linear bearings will play a crucial role in enabling more efficient and precise motion control across various sectors.

Design Principles and Functionalities of Linear Bearings

Linear bearings are designed with specific principles to facilitate controlled linear motion along a single axis. These design principles contribute to their functionalities, making them essential components in various applications:

- Rolling Elements:

Linear bearings typically feature rolling elements, such as balls or rollers, that move along a track or rail. These rolling elements reduce friction and enable smooth linear motion.

- Guiding Mechanism:

Linear bearings incorporate a guiding mechanism to constrain the motion to a single axis. This guiding mechanism ensures that the linear bearing moves precisely along the desired path.

- Load Distribution:

The design of linear bearings allows for effective distribution of loads, both in the radial and axial directions. This load distribution ensures stability and prevents excessive stress on individual components.

- Rail or Track:

Linear bearings typically run along a rail or track that provides a smooth and accurate path for the rolling elements. The rail is designed to resist wear and maintain its precision over time.

- Cage or Carriage:

Linear bearings use a cage or carriage to house the rolling elements and maintain their proper spacing. This arrangement ensures even load distribution and smooth movement.

- Sealing and Lubrication:

Linear bearings often incorporate sealing mechanisms to protect the rolling elements from contaminants and to retain lubrication. Proper lubrication ensures smooth motion and extends the bearing’s lifespan.

- Mounting Options:

Linear bearings are designed to be mounted in various ways, depending on the application’s requirements. Mounting options include flange-mounted, base-mounted, or end-supported configurations.

- Adjustability:

Many linear bearings are designed with provisions for adjustment, allowing users to fine-tune the preload or clearance to optimize performance and minimize play.

- Materials:

Linear bearings are constructed from materials that offer high wear resistance, durability, and corrosion resistance. Common materials include steel, stainless steel, and various engineering plastics.

- Accessories:

Accessories such as end caps, seals, and lubrication systems can enhance the functionality and lifespan of linear bearings by providing protection and ensuring proper maintenance.

Functionalities of linear bearings include providing precise linear motion, guiding components along a defined path, minimizing friction, distributing loads, and maintaining stability. The design principles ensure reliable operation and make linear bearings indispensable in applications requiring controlled and accurate linear motion.

editor by CX 2024-04-30