Product Description

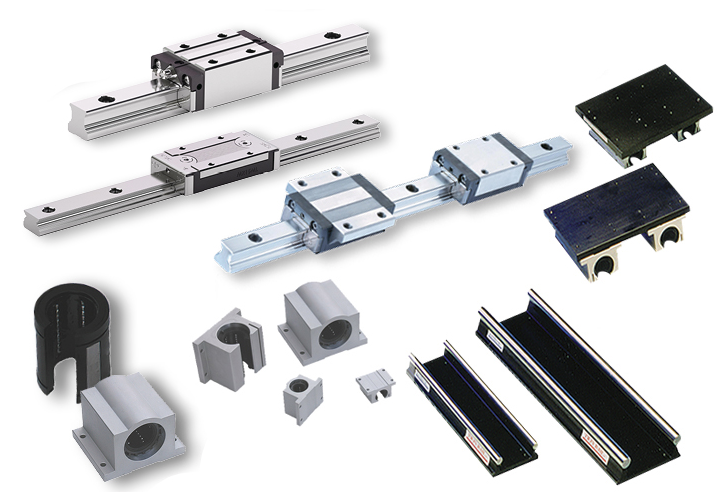

22207 Spherical Roller Bearings/Ball Bearings/Pillow Block Bearings/Linear Xihu (West Lake) Dis. Bearings

About Spherical Roller Bearing

1): CZPT to accommodate misalignment

2): Suitable for high axial and some radial loads

3): Relatively high speed ratings

4): type : YM (CA,CAM,EAS ) ,YMB ,MB,CJ(CC CD RH) ,E (E1)

5): Application examples: Heavy vertical shafts, injection moulding machines, etc.

| New Item | Old Item | Structure | Specifications(dxDxT)mm | Weight/kg |

| 22207 | 3507 | MB/CA/CC/EK/CK/CMW33 | 35x72x23 | 0.43 |

| 22208 | 3508 | MB/CA/CC/E/K/CK/CMW33 | 40X80X23 | 0.55 |

| 22209 | 3509 | MB/CA/CC/E/K/CK/CMW33 | 45X85X23 | 0.59 |

| 22210 | 3510 | MB/CA/CC/E/K/CK/CMW33 | 50X90X23 | 0.64 |

| 22211 | 3511 | MB/CA/CC/E/K/CK/CMW33 | 55X100X25 | 0.88 |

| 22212 | 3512 | MB/CA/CC/E/K/CK/CMW33 | 60X110X28 | 1.19 |

| 22213 | 3513 | MB/CA/CC/E/K/CK/CMW33 | 65X120X31 | 1.6 |

| 22214 | 3514 | MB/CA/CC/E/K/CK/CMW33 | 70X125X31 | 1.68 |

| 22215 | 3515 | MB/CA/CC/E/K/CK/CMW33 | 75X130X31 | 1.75 |

| 22216 | 3516 | MB/CA/CC/E/K/CK/CMW33 | 80X140X33 | 2.12 |

| 22217 | 3517 | MB/CA/CC/E/K/CK/CMW33 | 85X150X36 | 2.79 |

| 22218 | 3518 | MB/CA/CC/E/K/CK/CMW33 | 90X160X40 | 3.78 |

| 22219 | 3519 | MB/CA/CC/E/K/CK/CMW33 | 95X170X43 | 4.31 |

| 22220 | 3520 | MB/CA/CC/E/K/CK/CMW33 | 100X180X46 | 5.06 |

| 22222 | 3522 | MB/CA/CC/E/K/CK/CMW33 | 110X200X53 | 7.4 |

| 22224 | 3524 | MB/CA/CC/E/K/CK/CMW33 | 120X215X58 | 9.267 |

| 22226 | 3526 | MB/CA/CC/E/K/CK/CMW33 | 130X230X64 | 11.5 |

| 22228 | 3528 | MB/CA/CC/E/K/CK/CMW33 | 140X250X68 | 14.5 |

| 22230 | 3530 | MB/CA/CC/E/K/CK/CMW33 | 150X270X73 | 18.4 |

| 22232 | 3532 | MB/CA/CC/E/K/CK/CMW33 | 160X260X80 | 22.3 |

| 22234 | 3534 | MB/CA/CC/E/K/CK/CMW33 | 170X310X86 | 28.7 |

| 22236 | 3536 | MB/CA/CC/E/K/CK/CMW33 | 180X320X86 | 30.5 |

| 22238 | 3538 | MB/CA/CC/E/K/CK/CMW33 | 190X320X92 | 35.55 |

| 22240 | 3540 | MB/CA/CC/E/K/CK/CMW33 | 200X360X98 | 44.7 |

| 22244 | 3544 | MB/CA/CC/E/K/CK/CMW33 | 220X400X108 | 63 |

| 22248 | 3548 | MB/CA/CC/E/K/CK/CMW33 | 240X440X120 | 83.2 |

| 22252 | 3552 | MB/CA/CC/E/K/CK/CMW33 | 260X480X130 | 105 |

| 22256 | 3556 | MB/CA/CC/E/K/CK/CMW33 | 280X500X130 | 126 |

| 22260 | 3560 | MB/CA/CC/E/K/CK/CMW33 | 300X540X140 | 143 |

| 22306 | 3606 | MB/CA/CC/E/K/CK/CMW33 | 30x70x22 | 0.37 |

| 22307 | 3607 | MB/CA/CC/E/K/CK/CMW33 | 35x80x31 | 0.75 |

| 22308 | 3608 | MB/CA/CC/E/K/CK/CMW33 | 40x90x33 | 1.07 |

| 22309 | 3609 | MB/CA/CC/E/K/CK/CMW33 | 45x90x33 | 1.4 |

| 22310 | 3610 | MB/CA/CC/E/K/CK/CMW33 | 50x110x40 | 1.83 |

| 22311 | 3611 | MB/CA/CC/E/K/CK/CMW33 | 55x120x43 | 2.4 |

| 22312 | 3612 | MB/CA/CC/E/K/CK/CMW33 | 60x130x46 | 2.88 |

| 22313 | 3613 | MB/CA/CC/E/K/CK/CMW33 | 65x140x48 | 3.52 |

| 22314 | 3614 | MB/CA/CC/E/K/CK/CMW33 | 70x150x51 | 4.21 |

| 22315 | 3615 | MB/CA/CC/E/K/CK/CMW33 | 75x160x55 | 5.47 |

| 22316 | 3616 | MB/CA/CC/E/K/CK/CMW33 | 80x170x58 | 6.19 |

| 22317 | 3617 | MB/CA/CC/E/K/CK/CMW33 | 85x180x60 | 7.5 |

| 22318 | 3618 | MB/CA/CC/E/K/CK/CMW33 | 90x190x64 | 8.96 |

| 22319 | 3619 | MB/CA/CC/E/K/CK/CMW33 | 95x200x67 | 9.93 |

| 22320 | 3620 | MB/CA/CC/E/K/CK/CMW33 | 100x215x73 | 13 |

| 22322 | 3622 | MB/CA/CC/E/K/CK/CMW33 | 110x240x80 | 17.95 |

| 22324 | 3624 | MB/CA/CC/E/K/CK/CMW33 | 120x246x80 | 22.4 |

| 22326 | 3626 | MB/CA/CC/E/K/CK/CMW33 | 130x280x93 | 28.2 |

| 22328 | 3628 | MB/CA/CC/E/K/CK/CMW33 | 140x300x102 | 35.12 |

| 22330 | 3630 | MB/CA/CC/E/K/CK/CMW33 | 150x320x108 | 43.7 |

| 22332 | 3632 | MB/CA/CC/E/K/CK/CMW33 | 160x340x114 | 52.2 |

| 22334 | 3634 | MB/CA/CC/E/K/CK/CMW33 | 170x360x120 | 60.7 |

Our packing:

* Industrial pakage+outer carton+pallets

* sigle box+outer carton+pallets

* Tube package+middle box+outer carton+pallets

* According to your requirments

We have been engaged in foreign trade for more than 6 years and are well-known enterprises in ZheJiang

Province. The fixed assets of the machine are more than 2 million US dollars, and the annual foreign trade

sales volume exceeds 2 million US dollars.

We have extensive cooperation with countries in Asia, Europe, and the Americas. Including Russia, Ukraine,

elarus, Kazakhstan, Uzbekistan, Tajikistan, Spain, Mexico,India, Pakistan, Turkey, Vietnam and other industrial

areas.

SAMPLES

1.Samples quantity: 1-10 pcs are available.

2.Free samples: It depends on the model NO., material and quantity. Some of the bearings samples need client to pay samples charge and shipping cost.

3.It’s better to start your order with Trade Assurance to get full protection for your samples order.

CUSTOMIZED

The customized LOGO or drawing is acceptable for us.

MOQ

1.MOQ: 10 pcs mix different standard bearings.

2.MOQ: 3000 pcs customized your brand bearings.

OEM POLICY

1.We can printing your brand (logo,artwork)on the shield or laser engraving your brand on the shield.

2.We can custom your packaging according to your design

3.All copyright own by clients and we promised don’t disclose any info.

SUPORT

Please visit our bearings website, we strongly encourge that you can communicate with us through email,thanks!

We have all kinds of bearings, just tell me your item number and quantity,best price will be offered to you soon

The material of the bearings, precision rating, seals type,OEM service,etc, all of them we can make according to your requirement.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Brand: | OEM Service |

|---|---|

| Feature: | Low Price, High Speed, Long Life |

| Vibration: | Z1V1 Z2V2 Z3V3 |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Differences between Open-Type and Closed-Type Linear Bearings

Open-type and closed-type linear bearings are two common variations used in linear motion systems, each with its own advantages and considerations:

- 1. Open-Type Linear Bearings:

Open-type linear bearings, as the name suggests, have an open design that allows easy access to the bearing’s rolling elements and raceways. These bearings are characterized by:

- Quick Maintenance: Open-type bearings are easier to clean, lubricate, and inspect due to their open structure, making maintenance more convenient.

- Increased Contamination Risk: Because they are exposed, open-type bearings are more susceptible to dust, debris, and contamination, which can affect their performance and lifespan.

- 2. Closed-Type Linear Bearings:

Closed-type linear bearings are enclosed within a housing or carriage that provides protection from external elements. These bearings offer the following features:

- Enhanced Contamination Protection: Closed-type bearings are less vulnerable to contaminants and offer improved protection against dust, dirt, and debris, leading to longer service life.

- Reduced Accessibility: Maintenance and inspection of closed-type bearings might be more complex due to the need to disassemble the housing or carriage for access.

- Reduced Noise: The enclosed design of closed-type bearings can contribute to reduced noise levels, which is advantageous in noise-sensitive applications.

Choosing between open-type and closed-type linear bearings depends on the specific requirements of the application. If easy maintenance and accessibility are crucial, open-type bearings might be preferred. On the other hand, closed-type bearings offer better protection against contaminants and reduced noise, making them suitable for environments where cleanliness and quiet operation are essential.

Recent Advancements in Linear Bearing Technology

Recent years have seen significant advancements in linear bearing technology, leading to improved performance, reliability, and versatility. Some notable developments include:

- Nanotechnology: The integration of nanotechnology has allowed for the development of ultra-precision linear bearings with nanometer-scale accuracy. These bearings are ideal for applications requiring extremely fine movement and positioning.

- Smart Bearings: Advances in sensor technology have enabled the creation of smart linear bearings that can monitor parameters like temperature, load, and vibration in real time. This data helps in predictive maintenance and optimizing operational efficiency.

- Materials Innovation: New materials with enhanced properties, such as self-lubricating and corrosion-resistant coatings, have extended the lifespan of linear bearings and reduced the need for frequent lubrication and maintenance.

- Compact Designs: Manufacturers are designing more compact linear bearings to suit space-constrained applications while maintaining high load capacity and precision.

- Environmental Sustainability: There’s a growing emphasis on developing linear bearings with reduced environmental impact, including using eco-friendly materials and designs that require less energy to operate.

- Integration of IoT: Linear bearings are being integrated into the Internet of Things (IoT) networks, allowing them to communicate with other equipment and systems for seamless automation and optimization.

- Magnetic Levitation Bearings: Magnetic levitation (maglev) technology is being applied to linear bearings to create frictionless movement, reducing wear and enabling smoother and more precise motion.

- Advanced Coatings: Coatings with enhanced wear resistance, low friction, and improved thermal properties are being applied to linear bearings, extending their service life in challenging environments.

These advancements have contributed to the expanding range of applications where linear bearings can be used, from aerospace and automotive industries to medical devices and consumer electronics. As technology continues to evolve, linear bearings will play a crucial role in enabling more efficient and precise motion control across various sectors.

Linear Bearings: Definition and Applications

Linear bearings are mechanical components designed to facilitate smooth and controlled linear motion in a single direction. They are widely used across various industries to provide precise movement and guidance in applications where traditional rotary bearings are not suitable. Linear bearings offer several advantages and find use in a diverse range of applications:

- Precision Machinery:

Linear bearings are a fundamental part of precision machinery such as CNC machines, laser cutting equipment, and coordinate measuring machines. They ensure accurate movement and positioning of tools and components, enabling high-quality and intricate work.

- Industrial Automation:

In automated manufacturing and assembly lines, linear bearings play a critical role in moving robotic arms, conveyors, and various stages along predefined paths. Their ability to provide smooth and repeatable motion contributes to increased production efficiency.

- Medical Devices:

Linear bearings are essential in medical devices like diagnostic machines, imaging systems, and robotic surgical equipment. They enable precise movement and positioning required for accurate diagnoses and minimally invasive procedures.

- Packaging Machinery:

In packaging industries, linear bearings guide the motion of conveyor belts, sealing mechanisms, and labeling devices. These bearings ensure consistent and reliable packaging processes.

- Material Handling:

Linear bearings are used in various material handling equipment such as pick-and-place systems, automated warehouses, and sorting machines. They enable efficient movement of goods and materials with reduced friction and wear.

- Semiconductor Manufacturing:

In semiconductor fabrication, where extreme precision is crucial, linear bearings are employed in wafer handling, chip assembly, and inspection equipment. They ensure contamination-free motion and positioning of delicate components.

- Textile Machinery:

Textile machines use linear bearings for guiding yarn paths, thread tensioning, and controlling the movement of fabric during weaving and knitting. These bearings contribute to the quality and efficiency of textile production.

- Automotive Manufacturing:

Linear bearings are found in automotive assembly lines for tasks such as welding, painting, and component installation. They provide accurate movement and positioning of vehicle parts, contributing to the production process.

- Aerospace and Defense:

In aerospace applications, linear bearings are used in various mechanisms, including aircraft seats, control surfaces, and satellite deployment systems. Their reliability and precision are crucial in these demanding environments.

- Renewable Energy:

In wind turbines and solar panel manufacturing, linear bearings are used to adjust the positioning of blades, solar panels, and tracking systems. They contribute to the efficiency of renewable energy generation.

Overall, linear bearings offer precise, controlled, and smooth linear motion in diverse applications across industries. Their ability to guide and support loads while minimizing friction and wear makes them essential components for achieving accurate movement and improved operational efficiency.

editor by CX 2024-05-15

China best Customized Stainless Steel Bearing Linear Pillow Block Ball Bearing Spherical Roller Bearings with high quality

Product Description

Product Description

Product Description:

| Type | • Single Row Four Point Contact Ball Slewing Bearing • Single Row Crossed Cylindrical Roller Slewing Bearings • Double Row Ball Slewing Bearings •Double Row Roller/Ball Combination Slewing Bearing •Three-Row Roller Slew Ring Bearing |

| Rolling elements | Steel ball / Cylinder Roller |

| Rolling elements Material | GCr5/GCr15SiMn/Customized |

| Bearing Material | 50Mn/42CrMo/42CrMo4V /Stainless Steel,Alu,Customized |

| Cage Material | Nylon 1571/ Steel /Brass |

| Structure | Taper pin , Mounting holes,Inner ring ,Grease fitting,Load plug, Seals , Roller ,Spacer Balls or separators |

| Outer diameter | 50-10000mm |

| Bore size | 50-10000mm |

| Mounting hole | Through Hole/Tapped hole/Counterbore |

| Raceway hardness | 55-62HRC |

| Inner and outer ring modulation hardness |

229-269HB/Customized |

| Gear type | No gear ,Internal gear , External gear. |

| Embellish grease | EP2 lithium lubricating grease |

| Certificate | ABS.BV,DNV,ISO9001,GL,3.1,3.2 |

| Application area | Ladle turret,Stacker crane,Bucket wheel machine,Solar heliostat Tracking System,port crane, Cabling machine,tower crane , off shore platform,ferris wheel, Palletizing robot,Rotary metallurgical furnace,can packing machine,Wind blade transporter,shield tunneling machine,tube push bench,excavator |

| Brand Name | SoCare-MSI |

| Place of Origin | China |

| Warranty | 18 months |

| Payment term | T/T is our first choice |

|

Packing details |

1,Filling with anti-rust oil 2.Corved with Plastic paper 3.Corved with kraft paper 4.Corved with Blue tie 5.Put in wooden box |

Slewing ring bearings are large-size rolling bearings that can accommodate axial, radial and moment loads acting either singly or in combination and in any direction .They can perform both slewing (oscillating) movements as well as rotational movements. A slewing ring bearing consist of an inner ring, an outer ring and rolling elements (balls or cylindrical rollers) that are separated by polyamide spacers .The rings, 1 of which usually incorporates a gear ,are provided with holes to accommodate attachment bolts. The holes may be threaded. Generally , only the raceways in the rings are hardened and precision-ground.Integral seals made of acrylonitrile-butadiene rubber (NBR) keep the lubricant in, and contaminants out of the bearing. Slewing ring bearings are re-lubricated through grease fittings to reduce maintenance and operating costs.

Compared to traditional pivot arrangements, slewing ring bearing arrangements provide many design and performance advantages. The compactness and large inner diameter simplify the design of the bearing arrangement and its associated components .The low sectional height of these bearings means that the pinion lever can be kept short. In most cases only flat mounting surfaces on the associated components are needed.

Slewing ring bearings were originally designed to be mounted only on horizontal support structure, but can now be used successfully in vertical bearing arrangements .

Slewing ring bearings perform extremely well in a variety of applications such as:

¤ Access platforms

¤ Bucket wheel excavators

¤ Conveyor booms

¤ Cranes of all type

¤ Small ,medium and large excavators

¤ InHangZhou tables

¤ Ladle turrets

¤ Offshore applications

¤ Robots

¤ Railway bogies

¤ Rotary platforms

¤ Stackers

¤ Solar mirrors

¤ Tunnel boring machines

¤ Wind turbines

Introduction

SCB-TR Tri-Roller Bearings

Increased stiffness and capacity over SCB-XR and SCB-DT

OD size range up : 48″- 275″

Construction

-Three separate rows of rollers

-Top and bottom rollers transmit thrust and moment load

-Middle roller transmits radial loading

-Sealed

-Ring Configuration:

Non geared

External gear

Internal gear

-Grease fittings for lubrication

Applications

-Mining

-Stackers and reclaimers

-Heavy equipment

-Cranes

-Radar

-Boring machines

Company Profile

Company Profile:

About SoCare :

The SoCare brand is synonymous with quality.

Now, we have become an even greater resource for our business partners. Due to embracing technical advances, product support, and service, we have become a truly solutions-oriented supplier.

SoCare is creating greater value for our partners.

These advances all work together to bring our customers the added benefit of higher productivity. In addition, we provide application specific products, leading edge design simulation tools, on sight engineering support, plant asset efficiency programs, and advanced supply chain management.

With SoCare you can expect more!

Application:

Slewing ring bearings can be widely used in lifting & transport machinery, mining machinery, construction machinery, port hoisting machinery, port oil transfer equipment, onshore and offshore crane, excavator, concrete machine, paper machine, plastic and rubber machine, weave machine, steel plant, electronic power plant, wind power generator, other construction and industry machines or equipments and other large rotary device.

Packaging & Shipping

Packing & Shipping:

Bearing surface is covered with the anti-rust oil first; and then wrapped with the plastic film;

And then packed with kraft paper and professional belts;

At last, with wooden box totally at the outer packing to invoid the rust or the moist;

We can depend on the customers demand to be packed.

After Sales Service

Our Service:

♥ 1. Your inquiry will be reply within 2 hours.

♥ 2.Fast delivery,within 15 working days.

♥ 3.Packing: you will receive a Perfect product with strong outside packing.

♥ 4.With advanced first-level facilities and testing equipment,to insure no mistake on the dimension of the bearings.

♥ 5.MOQ is 2 sets, Because we are manufacturer.

♥ 6.24 hours on line,no limited to talk to us.

♥ 7.Return Policy:We gladly accept returns for item purchased within a 15 day period, provided it is still in the original package, not used nor damaged.

♥ 8.Warranty Claims :The Warranty covers any Defect of the product for a period of 18 months. It does not cover items that are not correctly installed or over tightened which may cause premature failure. Installation or any other fee’s are not refundable.

FAQ

FAQ:

1.Q: Are you trading company or manufacturer ?

A: We are a manufacturing enterprise focusing on bearings and integrating research, production and sales with 20 years’ experience.

2.Q: How long is your delivery time?

A: Generally it is 7 days if the goods are in stock. or it is 15 days if the goods are not in stock, Also it is according to quantity.

3.Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance, balance before shipment.

4.What are the company’s delivery terms?

A:We can accept EXW,FOB,CFR,CIF,etc. You can choose the 1 which is the most convenient cost effective for you.

5.Q: Can you provide special customization according to the working conditions?

A: Sure, we can design and produce the slewing bearings for different working conditions.

6.How many the MOQ of your company?

A:Depending on the size of the bearing, the MOQ is variable, if you are interested, you can contact me for a quote.

7.Does the company accept OEM or customized bearings?

A:In addition to standard products, we also supply non-standard and modified standard products for special application. Meanwhile, we provide OEM service.

8.Can the company provide free samples?

A:We can provide samples for free. You only need to provide shipping.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | High Speed, Corrosion-Resistant, Heat-Resistant |

| Sealing Gland: | Sealed On Both Sides |

| Rolling-Element Number: | Single-Row |

| Roller Type: | Spherical Raceway |

| Material: | Alloy |

| Samples: |

US$ 0/Set

1 Set(Min.Order) | |

|---|

Challenges and Solutions for Addressing Friction and Wear in Linear Bearings

Friction and wear are common challenges in linear bearings that can impact their performance and lifespan. Here are the challenges and some solutions to address them:

- 1. Challenge: Friction:

Friction between the bearing components can lead to increased energy consumption, heat generation, and reduced efficiency.

- Solution: Lubrication:

Proper lubrication is essential to minimize friction. Lubricants reduce the contact between moving parts, allowing smoother motion and reducing wear. Choosing the right lubricant and applying it correctly can significantly mitigate friction-related issues.

- 2. Challenge: Wear:

Continuous movement can lead to wear on the bearing surfaces, affecting precision and performance over time.

- Solution: Regular Maintenance:

Implementing a regular maintenance schedule can help monitor wear and replace worn components before they compromise performance. This includes cleaning, re-lubrication, and periodic inspection of the bearing’s condition.

- 3. Challenge: Contaminants:

Dust, debris, and foreign particles can enter the bearing system, leading to increased friction and accelerated wear.

- Solution: Sealing and Protection:

Using seals, covers, or protective enclosures can help prevent contaminants from entering the bearing system. These protective measures maintain the integrity of the lubricant and extend the bearing’s lifespan.

- 4. Challenge: Improper Installation:

If linear bearings are not installed correctly, misalignment and uneven load distribution can contribute to friction and wear.

- Solution: Precise Installation:

Follow manufacturer guidelines for proper installation, ensuring accurate alignment and even load distribution. This reduces the risk of premature wear and ensures optimal performance.

- 5. Challenge: Inadequate Lubrication:

If the linear bearings are under-lubricated or over-lubricated, it can lead to increased friction and wear.

- Solution: Lubrication Management:

Monitor and manage lubrication levels to ensure they are within the recommended range. Regularly assess the lubricant’s condition and replenish as needed to maintain optimal performance.

- 6. Challenge: High Loads and Speeds:

High loads and speeds can increase friction and wear on linear bearings.

- Solution: Proper Selection:

Select linear bearings that are designed to handle the specific loads and speeds of the application. This ensures that the bearings can operate effectively under the given conditions.

Addressing friction and wear challenges in linear bearings requires a combination of proper maintenance practices, appropriate lubrication, protective measures, and careful selection of bearings. By implementing these solutions, the performance and longevity of linear bearings can be optimized.

Recent Advancements in Linear Bearing Technology

Recent years have seen significant advancements in linear bearing technology, leading to improved performance, reliability, and versatility. Some notable developments include:

- Nanotechnology: The integration of nanotechnology has allowed for the development of ultra-precision linear bearings with nanometer-scale accuracy. These bearings are ideal for applications requiring extremely fine movement and positioning.

- Smart Bearings: Advances in sensor technology have enabled the creation of smart linear bearings that can monitor parameters like temperature, load, and vibration in real time. This data helps in predictive maintenance and optimizing operational efficiency.

- Materials Innovation: New materials with enhanced properties, such as self-lubricating and corrosion-resistant coatings, have extended the lifespan of linear bearings and reduced the need for frequent lubrication and maintenance.

- Compact Designs: Manufacturers are designing more compact linear bearings to suit space-constrained applications while maintaining high load capacity and precision.

- Environmental Sustainability: There’s a growing emphasis on developing linear bearings with reduced environmental impact, including using eco-friendly materials and designs that require less energy to operate.

- Integration of IoT: Linear bearings are being integrated into the Internet of Things (IoT) networks, allowing them to communicate with other equipment and systems for seamless automation and optimization.

- Magnetic Levitation Bearings: Magnetic levitation (maglev) technology is being applied to linear bearings to create frictionless movement, reducing wear and enabling smoother and more precise motion.

- Advanced Coatings: Coatings with enhanced wear resistance, low friction, and improved thermal properties are being applied to linear bearings, extending their service life in challenging environments.

These advancements have contributed to the expanding range of applications where linear bearings can be used, from aerospace and automotive industries to medical devices and consumer electronics. As technology continues to evolve, linear bearings will play a crucial role in enabling more efficient and precise motion control across various sectors.

Advantages of Linear Bearings over Other Bearing Types

Linear bearings offer several distinct advantages when compared to other types of bearings, particularly in applications that require controlled linear motion. These benefits contribute to their widespread use across various industries:

- Precise Linear Motion:

Linear bearings are designed specifically for linear motion, providing accurate and controlled movement along a defined path. This precision is essential in applications that demand accurate positioning and repeatability.

- Low Friction:

Linear bearings are designed to minimize friction during motion. The reduced friction translates to smoother movement, reduced wear, and improved efficiency, making them suitable for applications requiring consistent motion.

- High Load Capacity:

Linear bearings can handle significant loads in both radial and axial directions. This capability allows them to support heavy components and maintain stability under various loads.

- Minimal Maintenance:

Due to their design and minimal contact between moving parts, linear bearings require less maintenance compared to other types of bearings. This is particularly advantageous in hard-to-reach or inaccessible areas.

- Guided Motion:

Linear bearings provide guided and constrained motion along a single axis. This guidance eliminates the need for complex guiding mechanisms, reducing design complexity and simplifying assembly.

- Compact Design:

Linear bearings have a compact form factor, making them suitable for applications with limited space. Their small footprint allows for efficient use of available area.

- Low Noise and Vibration:

Linear bearings generate minimal noise and vibration during operation, contributing to quieter and more comfortable working environments in applications such as medical devices and precision machinery.

- Smooth Movement:

Linear bearings offer smooth and consistent movement, essential for applications requiring continuous and controlled motion, such as robotic systems and conveyor belts.

- Customization:

Linear bearings can be designed to fit specific application requirements, including load capacity, travel distance, and environmental conditions. This customization enhances their suitability for diverse applications.

- Reduced Wear:

The low friction and guided motion of linear bearings result in reduced wear on both the bearing and the mating surface, leading to longer service life and reduced maintenance costs.

Overall, the benefits of using linear bearings make them a preferred choice in applications that demand accurate linear motion, efficient load handling, and reduced maintenance. Their ability to deliver precision, stability, and reliability contributes to improved performance across various industries.

editor by CX 2024-03-27

China manufacturer CZPT CZPT CZPT CZPT Roller Bearings Distributor 22211cc/W33 Spherical Roller Bearing Ball Bearing/Roller Bearing/Linear Bearing/ Auto Bearing bearing example

Product Description

SKF CZPT CZPT Roller Bearings Distributor 22324cc/W33 Spherical Roller Bearing

NO 1. our adwantages:

1. 14 years bearing products manufacturing and 4 years exporting experiences.

2. OEM order and non-standard bearing order can be accepted.

3. Our main bearing products include Deep groove ball bearings, tapered roller bearings, cylindrical roller bearings, angular contact bearings, needle roller bearings, thrust ball bearings, spherical bearings, automotive bearings pump bearings, and many nonstandard bearings are also in our product range.

4. Sample available

NO 2. Description: Spherical roller bearing

Race: we use the most advanced technology-cold extrusion process. Besides, the race will make two or three times temper to guarantee its high precision.

Rolling element: we use the rolling technology to process the roller and the steel ball of high precision bearing, the most advantage of our technology is to promote productive and productive efficiency. At the same time, our technology can prolong the bearing working life. The hardness and the diamention stability will also promote.

Steel cage: in order to avoid avoid cracks and guarantee the hardness, we use pattern “high temperature+long time”, our cage of high precision bearing have reached advanced level in china at surface abrasion resistance and fatigue strength.

C(J), CC–Two window-type steel cages, flangeless inner ring and CZPT ring centred on the inner ring

EC(J), ECC(J)–Two window-type steel cages, flangeless inner ring, CZPT ring centred on the inner ring and reinforced roller complement.

CA–One-piece machined brass cage, double-pronged, retaining flanges on the inner ring and CZPT ring centred on the inner ring

CAF– As CA, but with a steel cage.

ECA, ECAC– Reinforced roller complement, one-piece machined brass cage, double-pronged, retaining flanges on the inner ring, CZPT ring centred on the inner ring.

ECAF– As ECA, but with a steel cage.

E– For bearings with a bore diameter d ≤ 65 mm: Two pressed window-type steel cages, flangeless inner ring and CZPT ring centred on the inner ring

CAFA– One-piece machined steel cage, double-pronged, centred on the outer ring raceway, retaining flanges on the inner ring and CZPT ring centred on the inner ring

Features:

- Double row spherical roller bearing for applications that support radial and oscillating axial loads

- C4 radial clearance allows thermal expansion for continuous operating temperatures up to 200 degrees C/392 degrees F

- Straight bore for fitting to a conventional cylindrical shaft

- Outer ring-guided brass cage evenly spaces rollers for reduced friction, vibration, and noise

- Open design, circumferential groove and 3 lubrication holes in the outer ring allow for lubrication in place

NO 3. OEM all brand bearing

1. deep groove ball bearing 6000,6200,6300,6400,61800,61900,Z,RS,ZZ,2RS

2. spherical roller bearing 22200,22300,23000,24000,23100,24100,CA,CC,E,W33

3. cylindrical roller bearing N,NU,NJ,NN,NUP,E,ECP,ECM,ECJ

4. taper roller bearing 35710,30300,32200,32300,31300,32000

5. Aligning ball bearing 1200,1300,2200,2300,

6. needle roller bearing NA,NAV,NK,NKI,RNA,NK,RNAV,ZKLF,ZKLN,ZARF,ZARN

7. thrust ball bearing 51100,51200,51300,51400,E,M

8. angular contact ball bearing7000,7100,7200,7300,AC,BECBM,C

9. spherical plain bearing GE,GEG,GEEW,U,UC,UG,GX,GAC,SA,SABP

10.Wheel hub bearing /ceramic bearing/plastic bearing/lazy susan bearing

NO 4. Spherical Roller Bearing Specification:

| Seals Types | 2RS,OPEN |

| Vibration Level | Z1V1,Z2V2,Z3V3 |

| Clearance | C2,C0,C3,C4,C5 |

| Tolerance Codes | ABEC-1,ABEC-3,ABEC-5 |

| Materral | GCr15-China/AISI52100-USA/Din100Cr6-Germany |

| MOQ | 1Set at least |

| Delivery Time | 5-15 days after contract |

| Payment Terms | TT/PAPAL/WESTERN UNION |

| Package | Tube package+outer carton+pallets; Single box+outer carton+pallets; Tube packge+middle box+outer carton+pallets; According to your requirement |

NO 5. Spherical roller bearing Models and Size:

|

Designation |

Principal Dimension |

(kN) |

(r/min) |

Mass |

|||||

|

d |

D |

B |

r |

Dynamic |

Static |

Grease |

Oil |

kg |

|

|

23032 |

160 |

240 |

60 |

2.1 |

376 |

730 |

1500 |

1900 |

13.5 |

|

24032CA |

160 |

240 |

80 |

2.1 |

636 |

1164 |

1100 |

1500 |

12.9 |

|

24132CA |

160 |

270 |

109 |

2.1 |

1571 |

1700 |

700 |

900 |

25.4 |

|

2638 |

190 |

280 |

67 |

2.5 |

542 |

978 |

1200 |

1500 |

13.7 |

|

23038K |

190 |

290 |

75 |

2.1 |

626 |

1100 |

1200 |

1500 |

20.5 |

|

23038CA |

190 |

290 |

75 |

2.1 |

765 |

735 |

1300 |

1700 |

16.9 |

|

24038CA |

190 |

290 |

100 |

2.1 |

980 |

1000 |

950 |

1300 |

22.8 |

|

23144CA |

220 |

370 |

120 |

4 |

1570 |

1520 |

900 |

1200 |

54.7 |

|

23144K |

220 |

370 |

120 |

4 |

1330 |

1330 |

900 |

1200 |

54.8 |

|

22244 |

220 |

400 |

108 |

4 |

1200 |

2100 |

850 |

1200 |

57.6 |

|

23244 |

220 |

400 |

144 |

4 |

1800 |

2820 |

670 |

850 |

94.6 |

|

22344/W33 |

220 |

460 |

145 |

5 |

1700 |

3090 |

670 |

850 |

129 |

|

23948CA |

240 |

320 |

60 |

2.1 |

635 |

710 |

1300 |

1700 |

14.9 |

|

23048 |

240 |

360 |

92 |

3 |

820 |

1800 |

900 |

1200 |

37.6 |

|

23048K/W33 |

240 |

360 |

92 |

3 |

820 |

1800 |

900 |

1200 |

37.4 |

|

23148 |

240 |

400 |

128 |

4 |

1200 |

2560 |

760 |

990 |

77.2 |

|

24148/W33 |

240 |

400 |

160 |

4 |

1200 |

3300 |

430 |

540 |

81.6 |

We can accept customized bearing service,besides,we can supply bearing with brand SKF, ZKL, NTN, NSK, KOYO, TIMKEN,NACHI, LYC, HCH, ZWZ

product-list-1.html

NO 6. Our Bearing Factory:

NO 8. Our Bearing Warehouse:

NO 9. Our Bearing Packaging Box:

Why Choose Us:

l HangZhou SFNB bearing company has 14 years manufacture experience and is one of the biggest adjustment center in north of China.

l We have large stock of original brand and our own brand bearing.

l Sample is available.

l We can accept OEM service.

l HangZhou SFNB Bearing Co., Ltd. Was founded in March 2008. We were principally engaged in the research, development and manufacture of bearings in the early stage. Now we are mainly engaged in the sales of internationally-famous brand bearings. Our products are sold in Britain, America, Japan, Italy and Southeast Asia, well appreciated by their purchasers.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Inner: | 55mm |

|---|---|

| Outer: | 100mm |

| Thickness: | 25mm |

| Rolling Body: | Roller Bearings |

| The Number of Rows: | Double |

| Outer Dimension: | Small and Medium-Sized (60-115mm) |

| Customization: |

Available

| Customized Request |

|---|

Considerations for Selecting the Right Type and Size of Linear Bearing

Choosing the appropriate type and size of linear bearing requires careful consideration of various factors to ensure optimal performance and compatibility with the application. Here are important considerations to keep in mind:

- 1. Load Capacity:

Determine the maximum load the linear bearing will need to support. Consider both static and dynamic loads to select a bearing that can handle the expected weight and forces.

- 2. Speed and Acceleration:

Assess the required speed and acceleration of the linear motion. Different linear bearing types have different speed limitations, so choose one that can accommodate the desired motion profile.

- 3. Precision and Accuracy:

If your application requires precise positioning, choose linear bearings that offer high accuracy and repeatability. Linear ball bearings are known for their precision, while linear roller bearings offer higher load capacity.

- 4. Environment:

Consider the operating environment, including temperature, humidity, dust, and potential exposure to chemicals. Select linear bearings that are designed to withstand the specific environmental conditions.

- 5. Rail or Shaft Compatibility:

Ensure that the chosen linear bearing is compatible with the rail or shaft you intend to use. Proper fit and alignment are crucial for smooth motion and long bearing life.

- 6. Space Constraints:

If your application has limited space, choose compact linear bearings that can fit within the available area without compromising performance.

- 7. Maintenance Requirements:

Consider the level of maintenance your application can accommodate. Some linear bearings are self-lubricating, reducing the need for frequent maintenance.

- 8. Noise Level:

For noise-sensitive environments, opt for linear bearings that provide quiet operation to avoid disruptions caused by excessive noise.

- 9. Mounting Options:

Consider how the linear bearing will be mounted and integrated into your system. Different bearings may require specific mounting configurations.

- 10. Cost and Budget:

Balance the desired features and performance with your budget constraints. While high-performance linear bearings may offer advanced features, they can also come at a higher cost.

By carefully evaluating these factors, you can choose the most suitable type and size of linear bearing for your specific application. Consulting with bearing manufacturers and engineers can also provide valuable insights to ensure the optimal selection.

Advancements in Linear Bearing Technology

Recent years have witnessed significant advancements in linear bearing technology, leading to improved performance and expanded applications. Some notable advancements include:

- Rolling Element Innovations:

Manufacturers are introducing new types of rolling elements, such as ceramic balls and specialized coatings, to enhance load capacity, reduce friction, and extend the lifespan of linear bearings.

- Lubrication Solutions:

Advanced lubrication techniques, including self-lubricating materials and greases with extended lifetimes, are being developed to optimize the performance of linear bearings while reducing maintenance needs.

- Smart and Sensor-Integrated Bearings:

Linear bearings with built-in sensors provide real-time data on temperature, vibration, and wear. This enables predictive maintenance, early fault detection, and optimization of bearing performance.

- Improved Corrosion Resistance:

New materials and coatings are being employed to enhance the corrosion resistance of linear bearings. This is particularly beneficial in environments where exposure to moisture and corrosive substances is a concern.

- Reduced Friction and Energy Consumption:

Advanced engineering and design techniques are leading to lower friction coefficients and reduced energy consumption in linear bearings. This not only improves efficiency but also contributes to sustainability efforts.

- High-Speed Capabilities:

Linear bearings capable of operating at higher speeds are being developed to meet the demands of applications requiring rapid and precise movements, such as in the semiconductor and electronics industries.

- Enhanced Sealing and Contaminant Management:

New sealing technologies are being employed to provide better protection against contaminants and debris. This is critical for applications where cleanliness is paramount.

- Integration with Industry 4.0:

Linear bearings are increasingly designed to be compatible with Industry 4.0 principles, allowing them to be integrated into digital manufacturing and automation systems for improved overall efficiency.

- Material Advancements:

Novel materials with improved mechanical properties, wear resistance, and temperature tolerance are being used in the production of linear bearings, expanding their operating capabilities.

These recent advancements in linear bearing technology are enabling industries to achieve higher levels of precision, efficiency, reliability, and predictive maintenance, making linear bearings an essential component of modern machinery and systems.

Linear Bearings: Definition and Applications

Linear bearings are mechanical components designed to facilitate smooth and controlled linear motion in a single direction. They are widely used across various industries to provide precise movement and guidance in applications where traditional rotary bearings are not suitable. Linear bearings offer several advantages and find use in a diverse range of applications:

- Precision Machinery:

Linear bearings are a fundamental part of precision machinery such as CNC machines, laser cutting equipment, and coordinate measuring machines. They ensure accurate movement and positioning of tools and components, enabling high-quality and intricate work.

- Industrial Automation:

In automated manufacturing and assembly lines, linear bearings play a critical role in moving robotic arms, conveyors, and various stages along predefined paths. Their ability to provide smooth and repeatable motion contributes to increased production efficiency.

- Medical Devices:

Linear bearings are essential in medical devices like diagnostic machines, imaging systems, and robotic surgical equipment. They enable precise movement and positioning required for accurate diagnoses and minimally invasive procedures.

- Packaging Machinery:

In packaging industries, linear bearings guide the motion of conveyor belts, sealing mechanisms, and labeling devices. These bearings ensure consistent and reliable packaging processes.

- Material Handling:

Linear bearings are used in various material handling equipment such as pick-and-place systems, automated warehouses, and sorting machines. They enable efficient movement of goods and materials with reduced friction and wear.

- Semiconductor Manufacturing:

In semiconductor fabrication, where extreme precision is crucial, linear bearings are employed in wafer handling, chip assembly, and inspection equipment. They ensure contamination-free motion and positioning of delicate components.

- Textile Machinery:

Textile machines use linear bearings for guiding yarn paths, thread tensioning, and controlling the movement of fabric during weaving and knitting. These bearings contribute to the quality and efficiency of textile production.

- Automotive Manufacturing:

Linear bearings are found in automotive assembly lines for tasks such as welding, painting, and component installation. They provide accurate movement and positioning of vehicle parts, contributing to the production process.

- Aerospace and Defense:

In aerospace applications, linear bearings are used in various mechanisms, including aircraft seats, control surfaces, and satellite deployment systems. Their reliability and precision are crucial in these demanding environments.

- Renewable Energy:

In wind turbines and solar panel manufacturing, linear bearings are used to adjust the positioning of blades, solar panels, and tracking systems. They contribute to the efficiency of renewable energy generation.

Overall, linear bearings offer precise, controlled, and smooth linear motion in diverse applications across industries. Their ability to guide and support loads while minimizing friction and wear makes them essential components for achieving accurate movement and improved operational efficiency.

editor by CX 2024-01-09

China Hot Sell 23026 caw33 Spherical Roller Bearings China Supply Bearing with Best Sales

Sort: Roller

Construction: Spherical

Applicable Industries: Hotels, Garment Stores, Building Materials Shops, Production Plant, Machinery Repair Outlets, Meals & Beverage Factory, Farms, Cafe, Residence Use, Retail, Foods Store, Printing Shops, Design works , Power & Mining, Food & Beverage Outlets, 1hp 1.5hp 2hp 3hp 4hp 5hp 7.5hp 10hp Electric powered AC Motor YE2Y2YMS Promoting Company

Model Variety: 23026 ca/w33, Spherical Roller Bearing

Precision Rating: P6

Seals Kind: Open

Number of Row: Double row

Item identify: Sizzling Market 23026 ca/w33 Spherical Roller Bearings China Source Bearing

Materials: Chrome Steel GCR15

Cage: Metal /Brass

Within Diameter:: one hundred thirty mm

Outdoors Diameter: 200 mm

Thickness: 52 mm

Vibration: V1, V2, V3, V4 /Z1, Z2, Z3, Z4

Clearance: C0,C2,C3, or as requested

Services: OEM Tailored Providers

Packaging Particulars: 1.Industrial packaging: Plastic tube (10pcs in 1 tube)+ carton + plywood pallets plastic bag + kraft paper + carton + plywood pallets 2.Industrial packing: 1pc/plastic bag+ one shade box+ carton + plywood pallets 3.According to customer’s demands

Port: HangZhou

A spherical roller bearing is a rolling-component bearing that permits rotation with minimal friction, and permits angular misalignment.Normally these bearings support a rotating shaft in the bore of the internal ring that may be misaligned in regard to the outerring.

| Product Title | Hot Promote 23026 ca/w33 Spherical Roller Bearings China Supply Bearing |

| Model | 23026 ca/w33 |

| Size | 130x200x2 mm |

| Type | Spherical Roller Bearing |

| New Product | Old Product | Structure | Specifications(dxDxT)mm | Weight/kg |

| 22207 | 3507 | MB/CA/CC/EK/CK/CMW33 | 35x72x23 | 0.forty three |

| 22208 | 3508 | MB/CA/CC/E/K/CK/CMW33 | 40X80X23 | 0.fifty five |

| 22209 | 3509 | MB/CA/CC/E/K/CK/CMW33 | 45X85X23 | 0.59 |

| 22210 | 3510 | MB/CA/CC/E/K/CK/CMW33 | 50X90X23 | 0.sixty four |

| 22211 | 3511 | MB/CA/CC/E/K/CK/CMW33 | 55X100X25 | 0.88 |

| 22212 | 3512 | MB/CA/CC/E/K/CK/CMW33 | 60X110X28 | 1.19 |

| 22213 | 3513 | MB/CA/CC/E/K/CK/CMW33 | 65X120X31 | 1.six |

| 22214 | 3514 | MB/CA/CC/E/K/CK/CMW33 | 70X125X31 | 1.68 |

| 22215 | 3515 | MB/CA/CC/E/K/CK/CMW33 | 75X130X31 | 1.seventy five |

| 22216 | 3516 | MB/CA/CC/E/K/CK/CMW33 | 80X140X33 | 2.twelve |

| 22217 | 3517 | MB/CA/CC/E/K/CK/CMW33 | 85X150X36 | 2.79 |

| 22218 | 3518 | MB/CA/CC/E/K/CK/CMW33 | 90X160X40 | 3.78 |

| 22219 | 3519 | MB/CA/CC/E/K/CK/CMW33 | 95X170X43 | 4.31 |

| 22220 | 3520 | MB/CA/CC/E/K/CK/CMW33 | 100X180X46 | 5.06 |

| 22222 | 3522 | MB/CA/CC/E/K/CK/CMW33 | 110X200X53 | 7.4 |

| 22224 | 3524 | MB/CA/CC/E/K/CK/CMW33 | 120X215X58 | 9.267 |

| 22226 | 3526 | MB/CA/CC/E/K/CK/CMW33 | 130X230X64 | 11.5 |

| 22228 | 3528 | MB/CA/CC/E/K/CK/CMW33 | 140X250X68 | 14.5 |

| 22230 | 3530 | MB/CA/CC/E/K/CK/CMW33 | 150X270X73 | 18.four |

| 22232 | 3532 | MB/CA/CC/E/K/CK/CMW33 | 160X260X80 | 22.three |

| 22234 | 3534 | MB/CA/CC/E/K/CK/CMW33 | 170X310X86 | 28.seven |

| 22236 | 3536 | MB/CA/CC/E/K/CK/CMW33 | 180X320X86 | 30.5 |

| 22238 | 3538 | MB/CA/CC/E/K/CK/CMW33 | 190X320X92 | 35.55 |

| 22240 | 3540 | MB/CA/CC/E/K/CK/CMW33 | 200X360X98 | 44.7 |

| 22244 | 3544 | MB/CA/CC/E/K/CK/CMW33 | 220X400X108 | 63 |

| 22248 | 3548 | MB/CA/CC/E/K/CK/CMW33 | 240X440X120 | 83.two |

| 22252 | 3552 | MB/CA/CC/E/K/CK/CMW33 | 260X480X130 | 105 |

| 22256 | 3556 | MB/CA/CC/E/K/CK/CMW33 | 280X500X130 | 126 |

| 22260 | 3560 | MB/CA/CC/E/K/CK/CMW33 | 300X540X140 | 143 |

| 22306 | 3606 | MB/CA/CC/E/K/CK/CMW33 | 30x70x22 | 0.37 |

| 22307 | 3607 | MB/CA/CC/E/K/CK/CMW33 | 35x80x31 | 0.seventy five |

| 22308 | 3608 | MB/CA/CC/E/K/CK/CMW33 | 40x90x33 | 1.07 |

| 22309 | 3609 | MB/CA/CC/E/K/CK/CMW33 | 45x90x33 | 1.4 |

| 22310 | 3610 | MB/CA/CC/E/K/CK/CMW33 | 50x110x40 | 1.83 |

| 22311 | 3611 | MB/CA/CC/E/K/CK/CMW33 | 55x120x43 | 2.four |

| 22312 | 3612 | MB/CA/CC/E/K/CK/CMW33 | 60x130x46 | 2.88 |

| 22313 | 3613 | MB/CA/CC/E/K/CK/CMW33 | 65x140x48 | 3.52 |

| 22314 | 3614 | MB/CA/CC/E/K/CK/CMW33 | 70x150x51 | 4.21 |

| 22315 | 3615 | MB/CA/CC/E/K/CK/CMW33 | 75x160x55 | 5.forty seven |

| 22316 | 3616 | MB/CA/CC/E/K/CK/CMW33 | 80x170x58 | 6.19 |

| 22317 | 3617 | MB/CA/CC/E/K/CK/CMW33 | 85x180x60 | 7.5 |

| 22318 | 3618 | MB/CA/CC/E/K/CK/CMW33 | 90x190x64 | 8.ninety six |

| 22319 | 3619 | MB/CA/CC/E/K/CK/CMW33 | 95x200x67 | 9.ninety three |

| 22320 | 3620 | MB/CA/CC/E/K/CK/CMW33 | 100x215x73 | 13 |

| 22322 | 3622 | MB/CA/CC/E/K/CK/CMW33 | 110x240x80 | 17.ninety five |

| 22324 | 3624 | MB/CA/CC/E/K/CK/CMW33 | 120x246x80 | 22.4 |

| 22326 | 3626 | MB/CA/CC/E/K/CK/CMW33 | 130x280x93 | 28.2 |

| 22328 | 3628 | MB/CA/CC/E/K/CK/CMW33 | 140x300x102 | 35.twelve |

| 22330 | 3630 | MB/CA/CC/E/K/CK/CMW33 | 150x320x108 | 43.7 |

| 22332 | 3632 | MB/CA/CC/E/K/CK/CMW33 | 160x340x114 | 52.2 |

| 22334 | 3634 | MB/CA/CC/E/K/CK/CMW33 | 170x360x120 | 60.seven |

| 22338 | 3640 | MB/CA/CC/E/K/CK/CMW33 | 190x400x132 | 85.5 |

Industrial applications of casing

For rotating and sliding parts, bushings are an important part of the machine. Due to their anti-friction properties and load-carrying capacity, they are an important part of many different industrial processes. Bushings play a vital role in industries such as construction, mining, hydropower, agriculture, transportation, food processing and material handling. To learn more about the benefits of bushings, read on. You’ll be amazed how much they can help your business!

type

When comparing enclosure types, consider the material and how it will be used. Oilite bushings are made of porous material that draws lubricant into the liner and releases it when pressure is applied. These are manufactured using a sintered or powered metal process. Copper and tin are the most commonly used materials for making copper bushings, but there are other types of metal bushings as well.

Another popular type is the plain bearing. This type reduces friction between the rotating shaft and the stationary support element. This type provides support and load bearing while relying on soft metal or plastic for lubrication. Journal bearings are used to support the linear motion of the engine crankshaft in large turbines. They are usually babbitt or hydrodynamic with a liquid film lubricant between the two halves.

The oil-impregnated paper sleeve is made of high-quality kraft insulating paper. These bushings contain two layers of capacitor grading, with the innermost layer electrically connected to the mounting flange. These are mature processes and are widely used in different voltage levels. CZPT Electric (Group) Co., Ltd. provides UHV DC and AC oil-impregnated paper wall bushings for environmental control rooms.

Electrical bushings are used to transmit electricity. These can be transformers, circuit breakers, shunt reactors and power capacitors. The bushing can be built into the bushing or through the bushing. The conductors must be able to carry the rated current without overheating the adjacent insulation. A typical bushing design has a conductor made of copper or aluminum with insulation on all other sides. If the bushing is used in a circuit, the insulation needs to be high enough to prevent any leakage paths.

Voltage and current ratings of electrical bushings. Solid type electrical bushings typically have a center conductor and a porcelain or epoxy insulator. These bushings are used in small distribution transformers and large generator step-up transformers. Their test voltage is typically around 70 kV. Subsequent applications of this bushing may require a lower halfway release limit. However, this is a common type for many other applications.

application

Various industrial applications involve the use of casing. It is an excellent mechanical and chemical material with a wide range of properties. These compounds are also packaged according to national and international standards. Therefore, bushings are used in many different types of machines and equipment. This article will focus on the main industrial applications of casing. This article will also explain what a casing is and what it can do. For more information, click here. Casing application

Among other uses, bushing assemblies are used in aircraft and machinery. For example, a fuel tank of an aircraft may include baffle isolator 40 . The bushing assembly 16 serves as an interface to the fuel tank, allowing electrical current to flow. It can also be used to isolate one component from another. In some cases, bushing assemblies are used to provide a tight fit and reduce electrical resistance, which is important in circuits.

The benefits of casing go beyond reducing energy transmission. They reduce lubrication costs. If two metal parts are in direct contact, lubrication is required. Thus, the bushing reduces the need for lubrication. They also allow parts of the car to move freely. For example, rubber bushings may begin to deteriorate due to high internal temperatures or cold weather. Also, oil can affect their performance.

For example, bushing CTs in oil and gas circuit breakers are used as window current transformers. It consists of a toroidal core and secondary windings. The center conductor of the bushing acts as the single-turn primary of the BCT. By tapping the secondary winding, the ratio between primary and secondary can be changed. This information can be found on the asset nameplate.

Among other uses, bushings are used in diagnostic equipment. These components require precise positioning. Fortunately, air sleeves are perfect for this purpose. Their frictionless operation eliminates the possibility of misalignment. In addition, products based on porous media help minimize noise. A casing manufacturer can advise you on the best product for your equipment. Therefore, if you are looking for replacement bushings for your existing equipment, please feel free to contact Daikin.

Material

Dry ferrule cores were selected for study and examined under an Olympus polarizing microscope (BX51-P). Core slices showing layers of aluminum foil with a distance of approximately 2 cm between adjacent capacitor screens. The aluminum foil surface has a multi-layered structure with undulations due to shrinkage and crepe. Differences between the two types of foils are also revealed.

A typical metal bushing material consists of a high-strength metal backing and a solid lubricant. These materials have higher load-carrying capacity and low friction during operation. Additionally, they are precision machined to tight tolerances. They also offer better thermal conductivity and better fatigue resistance. The accuracy of the metal bushing is improved due to the re-machining process that takes place after the bearing is assembled. Additionally, metal bushing materials are more resistant to wear than plastic bushing materials.

Plastic bushings are relatively inexpensive and readily available off the shelf. Also, the price of custom plastic bushings is relatively low. However, they are not recommended for heavy duty applications. Plastics degrade under high loads and can damage mating parts. Also, if the plastic bushings are not manufactured accurately, they can become misaligned. These are just some of the reasons for choosing metal bushings over plastic.

A mechanically bonded bushing 40 is placed over the stabilizer bar and compressed into the outer sleeve/bracket assembly. The outer metal member includes slotted holes that compensate for the tolerance stacking between the first and second bushing assemblies. Pre-assembly allows the assembly plant to receive a complete assembly ready for vehicle assembly, rather than sub-assembly at the vehicle manufacturing plant.

cost

Control arm bushings are a major component of modern vehicle suspension systems. Damaged bushings can negatively affect the handling and performance of your car. Replacing bushings on a car can cost $200 to $500. While that’s pretty cheap for a handful of control bushings, replacing the entire suspension system could set you back over $1,200. Thankfully, if you want to repair or replace the bushing yourself, you can do it yourself for a fraction of the cost.

If you decide to replace the control arm bushing yourself, it’s best to shop around for the best price. Many auto parts stores offer cheaper bushings that you don’t have to spend a fortune on. Even if you don’t drive for years, rubber can degrade and create cracks in the material. These cracks can be as deep as three-eighths of an inch. This makes it dangerous to drive a car with damaged control arm bushings.

Hiring a mechanic might be a good idea if you don’t like doing the work yourself. You can save money and time by repairing the control arm yourself, but you may have to hire a mechanic to do the job. Replacing the front sway bar bushing alone can cost between $450 and $900. While these components are relatively inexpensive, you can replace them for a better-handling car.

In some cases, sizing the bushings is a more economical option, but if you want to replace your entire suspension system, it’s better to buy a brand new lower limit. You can even save labor by buying a replacement part fork with a good lower portion. In addition to improving your car’s handling and ride, new bushings will add to your car’s overall value. If you are not sure which parts you need, ask your mechanic for a quote.

While the cost of replacing control arm bushings is relatively low, it’s a good idea to compare quotes from multiple mechanics. By getting multiple quotes for the same repair, you can save as much as $50 to $100 on the total cost of your car. In addition to labor costs, parts and labor can vary, so shop around to find the mechanic best suited for your car. There’s no reason to settle for sub-par service when you can save $50 or more!

editor by czh 2023-02-19

China Best Sales Ball Bearing Tapered Roller Bearing Spherical Roller Bearing Wheel Hub Bearing Needle Roller Linear Bearing Single Roller Bearings with high quality

Solution Description

Solution Description

Our precision deep groove ball bearings are designed for high precision, minimal sound, small vibration, high dependability and extended existence. They are mainly used in numerous types of electrical motors. They are also known as EMQ (Electrical Motor High quality) bearings.

EMQ bearings are commonly used in family appliances, toys, electrical energy resources, automobile motors and other fields. With best style, substantial dependability warmth remedy, precision manufacturing processes and high-quality grease, these goods perform much better on trustworthiness, vibration and sound amounts than common products generating them much more appropriate for electrical motor programs. These products can also be applied to most gearbox apps as properly.

About this item

- 6201-2RS Ball Bearing: This is the most well-known items thanks to its adaptability in programs. It is wonderful for apps that need higher speeds, small routine maintenance and lower running sounds.

- 6201 Deep Groove Metric Ball Bearings: is made up of an inner ring, outer ring, cage and the ball bearings, the bearings have deep raceway grooves. can provide substantial efficiency and large load ability.

- Ball bearing reward: Ball bearings is made of chrome steel highlighted spin at large speeds require lubrication and a clear atmosphere By having the ball bearings shielded ensure far better safety in opposition to grime and grease with a longer lifespan.

- 6201-2RS bearing is employed in a range of purposes from agricultural CZPT to conveying tools, electrical motors, CNC machinery, trucks, mining gear, teach, robotics, dental tools, elevators, rolling mills, ship rudder shafts, and family appliances.

- Our Service: 100% satification, To make positive our honest buyers have the very best purchasing experience, we supply 30-day return/ alternative service.If you are not pleased with the product, remember to make contact with us, we will refund you unconditionally.

- Extensive Software:Rolling bearings are used in a selection of programs from agricultural CZPT to conveying tools, robotics,dental tools, elevators, ship rudder shafts, skateboards, inline skates, scooters and , amongst other people.

- 6201-2RS Dimension:Interior Dia.=.47 inch, Outer Dia.=1.26 inch, Thickness=.39 inch

- Material:The bearing is produced of large top quality bearing steel, very good toughness and resistance to heavy loads(Artificial Grease Method included Wear-Resistant Additives and Substantial Temperature Grease can be rated to 410 F)

- Characteristics:Pre-lubricated, normal accuracy, less friction, higher speed, smooth and low noise

- Strictly Shielded:Shields on both sides of the bearing help to keep dust out.Premium Support & twelve Months Guarantee

- 6201-2RS (I.D.=12mm, O.D.=32mm, Thickness=10mm)

- The bearing is made of substantial high quality chrome steel (not carbon metal) for sturdiness and resistance to deformity below large masses.

- Equipment polished interior & outer race for the final in smooth large speed rolling

- Deep Groove Ball Bearings are 1 of the most extensively employed rolling bearings. They are utilized to accommodate radial and axial masses in each directions.

- Excellent for CZPT load uses: skateboards, Inline skates, scooters, inline blade electric motors, wheels of bicycle, motorcycle, electric powered CZPT electricity tool ect. in several other rolling programs

Specification

Model: 6201RS

Sealed Variety: Double Sealed

Substance: Bearing Steel

Warmth Remedy: Quenching

Dimension

Thick:10mm/ .4″

Internal Dia:12mm/ .forty seven”

Outer Dia:32mm / 1.26″

Bundle Content

5pcs x 6201RS Ball Bearing

Our Guarantee

Refund is confirmed if the product you received has any problem. ”

Welcome to Get in touch with Us

Your satisfation is our initial priority. We aims to provide our customers a happy searching encounter and concluded Soon after Sale Support. If you have any concern to solution, remember to feel free to make contact with us.

Thorough Pictures

Packaging & Shipping and delivery

Packaging Information

Packaging

A.Polybag +Box+Carton

B.B.Tube+Box+Carton

C.As for each customer’s request

We have sorts of deals, this sort of as plastic baggage, cartons, special packing containers. We use distinct deals dependent on the goods and our customers’ needs.

Port :ZheJiang

Lead Time:Shipped in thirty days soon after payment

Firm Profile

Our Positive aspects

The use of our deep groove ball bearing:

FAQ

If you have any other questions, you should come to feel free of charge to make contact with us as follows.

Q: Why CZPT you select us?

A. We offer the greatest good quality bearings with sensible price tag, reduced friction, lower sound and prolonged service existence.

B. With sufficient inventory and quickly delivery, you can choose our freight forwarder or your freight forwarder.

C. The greatest services offered by a well-trained global sales team.

Q: Do you take tiny orders?

100% good quality examine, as soon as your bearings are common dimensions bearings, even 1, we also settle for.

Q: How extended is your shipping and delivery time?

Normally speaking, if the merchandise are in stock, it is 1-3 days. If the products are out of stock, it will take 6-10 times, relying on the quantity of the order.

Q: Do you give samples? Is it totally free or extra?

Of course, we can supply a small sum of free samples. Do you thoughts having to pay the freight?

Q: What need to I do if I don’t see the kind of bearings I need?

We have too a lot of bearing sequence numbers. At times we can’t place them all on world wide web. Just ship us the inquiry and we will be quite content to send out you the bearing information.

Welcome to speak to me anytime!

Advantages of Ball Bearings

What is a ball bearing? A ball bearing is a type of rolling-component bearing that makes use of balls to sustain separation in between two bearing races. Its speak to angle in between the balls and the races aids it lessen friction amongst the masses. There are a number of rewards to ball bearings, like their capability to stand up to drinking water. Study on to understand much more. Right here are a couple of of the benefits. You can use them in your everyday life, from your car to your boat.

Ball bearings lessen friction amongst hundreds

Ball bearings reduce friction in between loads by constraining the relative movement among transferring components. These bearings consist of a ring of small metallic balls that reduce friction in between transferring objects. The name “ball bearing” is derived from the verb “to bear.” The lubricant in the bearing lowers friction in between shifting particles. In a equipment, ball bearings minimize friction between moving elements and improve linear motion all around a fixed axis.

These bearings are generally utilized to decrease friction among hundreds in rotating machines. They have two tracks, a single mounted to the rotating portion and 1 stationary. The rolling balls of a ball bearing have decrease friction than flat surfaces. Because of this, they are valuable for bar stool bearings. They minimize friction in between surfaces and preserve the separation among bearing races. That’s why, small surface area make contact with is possible. Ball bearings have the prospective to increase the life of equipment and decrease energy use.

Ball bearings can be as little as a wrist view or as big as an industrial motor. They operate the identical way, lowering friction between masses. Amongst their numerous makes use of, ball bearings are essential for daily functions. Clocks, air conditioners, supporters, and auto axles all use ball bearings. In simple fact, anything at all that utilizes a motor demands ball bearings. It really is no ponder they’re getting acceptance in industries and each day existence.

They help radial and axial masses

Radial ball bearings are employed mostly for radial hundreds, but they also have a ability for axial load. This load ability is usually offered as a proportion of the radial load ranking. Axial load potential is usually higher for a bearing with a more substantial big difference in between the internal and outer ring diameters. The axial load potential is also afflicted by the bearing’s raceway depth, with shallow raceways becoming much more ideal for heavier axial loads.

The two primary varieties of axial and radial hundreds are described by their orientation. Axial loads use forces in a single course whilst radial loads act on the opposite route. In equally circumstances, the bearing need to assistance the forces that are imposed. Axial hundreds utilize forces to a bearing in a one course, even though radial hundreds implement forces in each directions. No matter of the type of load, axial and radial masses must be regarded when picking a bearing for a provided application.

Angular and radial ball bearings differ in their resources. Radial ball bearings are manufactured mainly of via-hardened materials. They normally have a Rockwell hardness ranking of fifty eight Rc. The raceways and balls of these bearings are created of 440C stainless steel. They may also contain shields and seals. SAE 52100 metal is the most frequent material for the raceway, even though molybdenum steels are exceptional for higher temperatures.

They have a speak to angle in between the balls and the races

When evaluating axial load bearings with their radial counterparts, the angular get in touch with angle is more crucial. Axial load bearings, have a contact angle between the balls and the races of 35 levels. They are suitable for axial hundreds and a constrained radial load. The make contact with angle of these bearings is a outcome of the condition of the internal and outer rings. Every single rolling component arrives into make contact with with the interior and outer rings only at one stage, forming a thirty degree angle with the radial plane. The radial drive of the axial load on these bearings is for that reason increased by rising the contact angle in between the balls and the races.

This speak to angle establishes the volume of friction between the balls and the races, and allows angular get in touch with bearings to withstand hefty radial and thrust hundreds. In addition, the more substantial the get in touch with angle, the higher the axial load assistance. Angular get in touch with bearings appear in standard imperial (inch) and metric (mm) dimensions. The angular contact angle is identified by the cost-free radial engage in worth and the curvature of the inner monitor.

They are drinking water-resistant

In addition to their h2o-resistant traits, corrosion-resistant ball bearings can also defend in opposition to the detrimental consequences of corrosive environments. Generally, standard metals, this kind of as metal, are inclined to rust, which can significantly reduce their functionality and prolong the life of parts. Nonetheless, plastics, stainless steel, and ceramics can provide corrosion-resistant ball bearings. And due to the fact these resources are much much more durable, they provide other benefits, such as being straightforward to sustain.

Amid the advantages of plastic ball bearings is their higher resistance to excessive temperatures, substantial speeds, and corrosion. Based on their design, plastic bearings are usually able to resist corrosion and anti-static qualities. They are lightweight and inexpensive when compared to steel ball bearings. CZPT Income Corporation was recognized in 1987 with a modest turnover of four lacs. As of the previous financial yr, it has developed to five hundred lacs in sales.

Other rewards of h2o-resistant ball bearings consist of corrosion resistance, which is a crucial consideration in several apps. Although stainless metal is highly corrosion-resistant, it decreases the bearing’s load-carrying capacity. Also, corrosion-resistant deep groove ball bearings are usually created with a specified inside clearance, which absorbs reduction in clearance during mounting and shaft expansion. This issue impacts their overall performance, and if these are compromised, a substitute could be required.

They are tough

A few things make ball bearings hard: they’re made of genuine resources, which indicates that they have inherent imperfections. Grade-1 balls are created particularly for large-pressure programs, this sort of as Formula One particular engines. Quality-3 balls, on the other hand, strike the ideal balance in between functionality and price. Ceramic balls, for case in point, are manufactured to spin at a large fee of 400 RPM, and they are concluded with a mirror complete.

A metal carbon ball bearing is a single of the toughest types of ball bearings accessible. The material is extremely sturdy, but the contact between the balls just isn’t the greatest. Low-carbon steel is very best for linear shafting and is normally coated with a polymer to avert damage. Metal ball bearings with average amounts of carbon are hard, sturdy, and h2o-resistant. They’re ideal for gears, but their high-carbon metal counterparts are particularly difficult and can resist corrosion.

A ceramic ball bearing is another choice. This type has steel interior and outer rings but ceramic balls. Ceramic balls can withstand larger temperatures than metal and are also electrically insulating. Ceramic ball bearings also are inclined to be lighter and are much more resistant to put on and tear. They’re also excellent for applications in which grease is not an selection, such as in room shuttles. Regardless of the truth that ceramic ball bearings are tough, they are nevertheless more affordable than steel ball bearings.

They are conductive

You could have read the time period “ball bearing” if you’ve examined introductory physics. What does that mean? Essentially, ball bearings are conductive due to the fact of their potential to perform electrical power. This potential is reflected in the charge distribution on the floor of the ball. Positive charges are drawn toward the positive plate, while adverse fees are drawn absent from the positively charged ball bearing. You could have even noticed a ball bearing in action.

Nonetheless, regardless of their conductive nature, ball bearings can nevertheless grow to be ruined by electrical discharge. A increased voltage can result in the balls to pit, and the raceways to turn out to be uneven. These uneven surfaces will first demonstrate up as abnormal sound, and sooner or later result in the bearing to malfunction. Thankfully, engineers have located a way to counter this difficulty: conductive grease. This grease allows current to stream by means of the ball bearing, preventing the two heat and voltage buildup.

The distinction amongst steel and ceramic ball bearings is their density. Steel bearings are more conductive than glass or hybrid ceramics. Metal ball bearings have an even grain framework and are conductive for resonance movement. When shifting fast, the air encompassing the metal ball bearing carries resonance from the inner ring to the outer. This makes them perfect for higher-velocity resonance transfer. In addition to being conductive, glass microbeads are more challenging and lighter than metal.

They are employed in pulley techniques

Pulley programs use ball bearings to transfer the sprocket, which is a wheel that rotates. These bearings are set up on the heart mounting gap of the pulley wheel. They safeguard the entire technique from warmth, although allowing increased velocity and clean operation. They distribute the weight of the load evenly, reducing friction and wobbling, and ensure a smooth rotation. Ball bearings are usually created from steel and are set up inside the pulley wheel.

The minute of inertia and bearing friction are measured to inside of ten per cent accuracy. These two variables influence the velocity of the pulley program, which can guide to crashes if the excess weight holders are not balanced. As a result, ball bearings are utilized to reduce the likelihood of this kind of crashes. When you want to know far more about ball bearings in pulley systems, here are the positive aspects they provide.