Product Description

Product Description

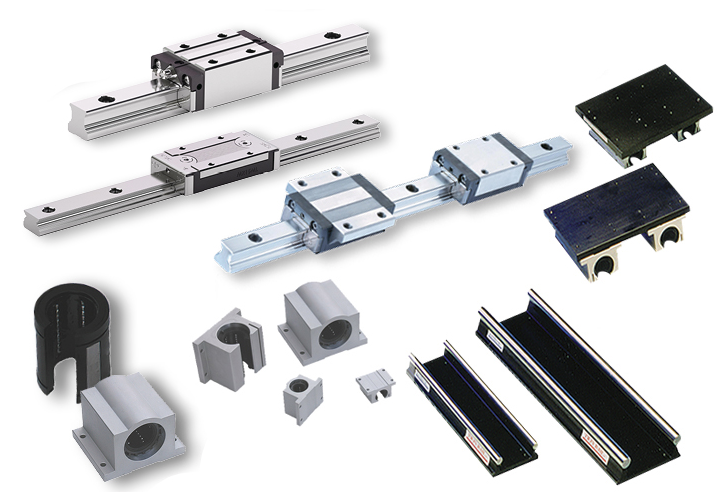

CNC Machines Equipment LMH6LUU LMH8LUU LMH10LUU LMH12LUU LMH13LUU LMH16LUU LMH20LUU LMH25LUU LMH30LUU LMH35LUU LMH40LUU LMH50LUU LMH60LUU Linear Bearing

Introducing The High Sensitivity Linear Bearing, A Cutting-Edge Product Designed To Revolutionize Your Industrial Operations. Crafted With Utmost Precision And Engineered To Perfection, This Linear Bearing Guarantees Unparalleled Performance And Reliability. Whether You Are In The Manufacturing, Automation, Or Robotics Industry, This Product Is An Essential Component That Will Elevate Your Machinery To New Heights.

The High Sensitivity Linear Bearing Boasts Exceptional Durability And Longevity, Ensuring A Prolonged Lifespan Even In The Most Demanding Environments. Its Robust Construction, Coupled With Advanced Materials, Enables It To Withstand Heavy Loads And Resist Wear And Tear, Making It An Ideal Choice For High-Intensity Applications. With This Linear Bearing, You Can Rest Assured That Your Equipment Will Operate Smoothly And Efficiently, Minimizing Downtime And Maximizing Productivity.

| Product name | Linear Bearing |

| Trademark (brand) | ANLD/OEM |

| port | HangZhou/HangZhou/ZheJiang /HangZhou/HangZhou |

| Services | Provide OEM services. |

| payment method | L/C or T/T or D/P or Paypal |

| Feature | Long Life, High Speed, Low Noise,Small friction resistance, not easy to damage |

The High Sensitivity Linear Bearing Is Compatible Making It A Versatile Solution For Various Machinery And Equipment. Its Seamless Integration And Easy Installation Process Make It A Hassle-Free Addition To Your Existing Systems. Furthermore, This Linear Bearing Requires Minimal Maintenance, Saving You Valuable Time And Resources.

Featuring The Latest Technological Advancements, This Linear Bearing Offers Unrivaled Precision And Accuracy. Its High Sensitivity Allows For Precise Linear Motion, Ensuring Optimal Performance And Reducing The Risk Of Errors. This Level Of Precision Is Crucial In Industries Where Accuracy Is Paramount, Such As Cnc Machining, 3d Printing, And Medical Equipment Manufacturing.

Invest In The High Sensitivity Linear Bearing Today And Experience The Difference It Can Make In Your Operations. With Its Exceptional Durability, Precision, And Compatibility, This Product Is A Game-Changer In The World Of Linear Bearings. Trust In Our Expertise And Join Countless Industry Professionals Who Have Already Benefited From This Innovative Solution. Elevate Your Machinery To New Heights With The High Sensitivity Linear Bearing.

We Understand That Reliability And Performance Are Crucial Factors When Choosing A Linear Bearing. That Is Why Our Product Undergoes Rigorous Quality Control Measures To Meet The Highest Industry Standards. We Prioritize Customer Satisfaction And Strive To Provide You With A Product That Exceeds Your Expectations.

Whether You’Re Looking For A Reliable Bearing For Use In Automotive Manufacturing, Or You Need A High-Quality Component For Use In Precision Machinery, The High Precision For Auto Parts Deep Groove Ball Bearing Is The Perfect Choice. With Its Exceptional Performance, Reliability, And Precision, This Ball Bearing Is Sure To Exceed Your Expectations And Deliver Outstanding Results.

So Why Wait? If You’Re Looking For A Top-Quality Deep Groove Ball Bearing That Can Deliver Exceptional Performance And Reliability, Look No Further Than The High Precision For Auto Parts Deep Groove Ball Bearing. Order Yours Today And Experience The Difference For Yourself!

Detailed Photos

Product Parameters

Factory Inspection Is The Final Inspection That Must Be Carried Out On The Formally Produced Products At The Time Of Delivery To Check Whether The Quality Of The Products At The Time Of Delivery Has The Quality Confirmed In The Type Inspection. Products Can Be Delivered As Qualified Products Only After Passing The Factory Inspection.

Furthermore, Our Company Understands The Importance Of Timely Delivery And Excellent Customer Service. We Strive To Provide A Seamless Purchasing Experience, Ensuring That Your Orders Are Processed Efficiently And Delivered Promptly. Our Knowledgeable And Friendly Customer Support Team Is Always Available To Address Any Inquiries Or Concerns You May Have, Ensuring Your Satisfaction With Our Products And Services.

We Will Check All The Quality Before We Deliver The Goods To The Customer.

Packaging & Shipping

Logistics Refers To The Physical Flow Process From The Place Of Supply To The Place Of Receipt. Logistics Industry Is A Compound Or Aggregation Industry Formed By The Industrialization Of Logistics Resources.

Why Is Logistics Important?

• Create Added Value: Logistics Can Help Retailers Create Added Value By Ensuring They Can Deliver The Right Quality And Quantity Of Products To Their Customers. Logistics Means You Can Manage Your Entire Business More Efficiently.

•Increasing Efficiency: As Global Trade Becomes More Popular, Logistics Is Becoming An Important Part Of The Supply Chain, Reducing Costs Through Effective Collaboration With Other Businesses And Suppliers.

•Cost Savings: If You Have A Well-Managed Logistics Strategy, You Reduce The Risk That Something Will Go Wrong And Cause You To Spend Extra Money.

• Provide A Better Customer Experience: Logistics Ensures That Customers Get The Items They Want At The Quality They Expect. By Better Organizing Logistics, Businesses Can Respond Quickly To Customer Needs.

• Enhance Brand Reputation: Logistics Shows That Your Business Processes Have Been Properly Addressed, So You Can Deliver The Amazing Results Your Customers Expect. The Result Is Usually A Better Brand Image And More Sales.

We Have A Professional Logistics Company For Transportation, To Ensure That The Goods Can Be Delivered On Time And Safely

Company Profile

At HangZhou Chaokun Bearing Co.,Ltd, We Take Pride In Delivering Products That Exceed Industry Standards.With Its Exceptional Performance, Durability, And Precision, This Bearing Is Set To Elevate Your Industry Systems To New Heights.

HangZhou Chaokun Bearing Co., Ltd. Is A Research And Development Production And Sales In One Physical Factory,

The Main Products

• Deep Groove Ball Bearings

• Aligning Ball Bearings

• Cylindrical Roller Bearings

• Self-Aligning Roller Bearings

• Outer Spherical Bearings

• Angular Contact Bearings

• Thrust Ball Bearings

• Thrust Roller Bearings

The Chinese Brand CZPT CZPT Hrb C&U 2rs Ball Bearing Is A Top-Notch Product That Delivers Exceptional Performance And Reliability. With Its Advanced Design, Superior Sealing, And Trusted Brand Reputation, This Ball Bearing Is The Ideal Choice For Any B2b Platform. Trust In CZPT CZPT Hrb C&U To Provide You With The Highest Quality Bearings For Your Industrial Needs.

Our Advantages

Our advantage

1. OEM or Non-Stand Bearings: Any requirement for Nonstandard bearings is Easily Fulfilled by us due to its vast knowledge.

2. Genuine products With Excellent Quality: The company has always proved the 100% quality products it provides with genuine intent.

3. After Sales Service and Technical Assistance: The company provides after-sales service and technical assistance as per the

customer’s requirements and needs.

4. Quick Delivery: The company provides just-in-time delivery with its streamlined supply chain.

We Will Give The Factory Wholesale Price

FAQ

OEM policy

1. We can print your brand (logo, artwork) on the shield or laser engraving your brand on the shield.

2. We can customize your packaging according to your design

3. All copyright belongs to the customer, we promise not to disclose any information.

What is the minimum order

•Depending on the model, you can send me information for your calculati.

Are you a factory(manufacturer)

Yes, we have been engaged in bearing development and manufacturing industry for more than 20 years.

Which payment method does your company support

Do our best to meet customer needs, negotiable

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Low Temperature, Corrosion Resistant, High Temperature, High Speed |

|---|---|

| Function: | for Linear Travel |

| Flange Shape: | Square Trimmed Type Circular Ellipse |

| Shape: | Straight Cylinder/Flange/Open |

| Series: | Lmf |

| Material: | Stainless Steel/Bearing Steel |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Considerations for Selecting the Right Type and Size of Linear Bearing

Choosing the appropriate type and size of linear bearing requires careful consideration of various factors to ensure optimal performance and compatibility with the application. Here are important considerations to keep in mind:

- 1. Load Capacity:

Determine the maximum load the linear bearing will need to support. Consider both static and dynamic loads to select a bearing that can handle the expected weight and forces.

- 2. Speed and Acceleration:

Assess the required speed and acceleration of the linear motion. Different linear bearing types have different speed limitations, so choose one that can accommodate the desired motion profile.

- 3. Precision and Accuracy:

If your application requires precise positioning, choose linear bearings that offer high accuracy and repeatability. Linear ball bearings are known for their precision, while linear roller bearings offer higher load capacity.

- 4. Environment:

Consider the operating environment, including temperature, humidity, dust, and potential exposure to chemicals. Select linear bearings that are designed to withstand the specific environmental conditions.

- 5. Rail or Shaft Compatibility:

Ensure that the chosen linear bearing is compatible with the rail or shaft you intend to use. Proper fit and alignment are crucial for smooth motion and long bearing life.

- 6. Space Constraints:

If your application has limited space, choose compact linear bearings that can fit within the available area without compromising performance.

- 7. Maintenance Requirements:

Consider the level of maintenance your application can accommodate. Some linear bearings are self-lubricating, reducing the need for frequent maintenance.

- 8. Noise Level:

For noise-sensitive environments, opt for linear bearings that provide quiet operation to avoid disruptions caused by excessive noise.

- 9. Mounting Options:

Consider how the linear bearing will be mounted and integrated into your system. Different bearings may require specific mounting configurations.

- 10. Cost and Budget:

Balance the desired features and performance with your budget constraints. While high-performance linear bearings may offer advanced features, they can also come at a higher cost.

By carefully evaluating these factors, you can choose the most suitable type and size of linear bearing for your specific application. Consulting with bearing manufacturers and engineers can also provide valuable insights to ensure the optimal selection.

Contribution of Linear Bearings to Smooth Movement of Conveyors and Slides

Linear bearings play a crucial role in ensuring the smooth movement and operation of industrial conveyors and linear slides. Their contributions are as follows:

- Reduced Friction:

Linear bearings are designed to minimize friction between moving components, facilitating smooth motion of conveyors and linear slides. This reduces wear and tear, energy consumption, and the need for frequent maintenance.

- Precision Movement:

Linear bearings enable precise positioning and controlled movement. This precision is vital for conveyors and slides that require accurate placement of materials, products, or components.

- Stability and Load Distribution:

Linear bearings distribute loads evenly across the bearing surface, enhancing stability and preventing uneven wear. This is especially important for conveyors that handle varying loads and linear slides that support heavy components.

- Quiet and Vibration-Free Operation:

Linear bearings contribute to quiet and vibration-free operation. This is crucial in environments where noise reduction and minimal vibrations are essential for the comfort of operators and the integrity of products.

- Efficient Energy Transfer:

Linear bearings ensure efficient energy transfer by reducing energy losses due to friction. This efficiency is particularly beneficial in systems where multiple conveyors or slides are connected, improving overall system performance.

- Longevity and Reliability:

Linear bearings enhance the longevity and reliability of conveyors and slides by reducing wear on moving parts. This results in extended operational lifespans and reduced downtime for maintenance.

- Flexibility and Customization:

Linear bearings come in various designs and sizes, allowing for customization to suit specific conveyor or slide requirements. This adaptability is valuable for accommodating different loads and motion profiles.

- Wide Range of Industries:

Linear bearings find application in industries such as manufacturing, logistics, packaging, and material handling, where conveyors and linear slides are essential components of the workflow.

In summary, linear bearings contribute significantly to the efficient, precise, and reliable movement of industrial conveyors and linear slides. Their ability to reduce friction, ensure stability, and support heavy loads enhances the overall performance of these systems.

Factors to Consider When Selecting a Linear Bearing

Choosing the right linear bearing for a specific application involves considering several critical factors to ensure optimal performance and longevity:

- Load Requirements:

Determine the magnitude and direction of the loads the linear bearing will experience. Consider both static and dynamic loads to select a bearing with an appropriate load capacity.

- Precision and Accuracy:

For applications requiring precise positioning, choose linear bearings with high precision and low backlash. Factors like repeatability and positional accuracy are crucial.

- Speed and Acceleration:

Consider the speed and acceleration at which the linear bearing will operate. Higher speeds may require bearings with lower friction and better heat dissipation.

- Environmental Conditions:

Assess the environmental factors such as temperature, humidity, and exposure to contaminants. Choose linear bearings with suitable materials and seals to withstand the conditions.

- Space Constraints:

Take into account the available space for mounting the linear bearing. Some applications may have limited space, necessitating compact and lightweight bearing options.

- Maintenance Requirements:

Consider the maintenance needs of the bearing. Bearings with self-lubricating properties or easy access for lubrication can reduce maintenance frequency.

- Mounting and Configuration:

Choose a linear bearing that can be easily mounted and integrated into your system’s design. Consider factors like mounting orientation and available mounting surfaces.

- Life Expectancy:

Estimate the expected lifespan of the linear bearing based on the application’s requirements. Select a bearing with a suitable design life to prevent premature failures.

- Cost and Budget:

Balance the desired performance with the available budget. Opt for linear bearings that provide the necessary features without exceeding cost limitations.

- Accessories and Add-ons:

Consider any additional accessories or add-ons, such as seals, lubrication systems, or end caps, that can enhance the bearing’s performance and protection.

- Manufacturer and Supplier:

Choose reputable manufacturers and suppliers that offer reliable products and good customer support. Quality assurance and technical assistance are essential.

Overall, a comprehensive assessment of these factors will help you select the most suitable linear bearing for your specific application, ensuring optimal performance, longevity, and cost-effectiveness.

editor by CX 2024-05-06